A steel truss assembly support adjustment device

An adjustment device and steel truss technology, applied in the preparation of pillars and building components on site, construction, etc., can solve the problems of increased operating costs, low work efficiency, occupation, etc., and achieve simple disassembly, low cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

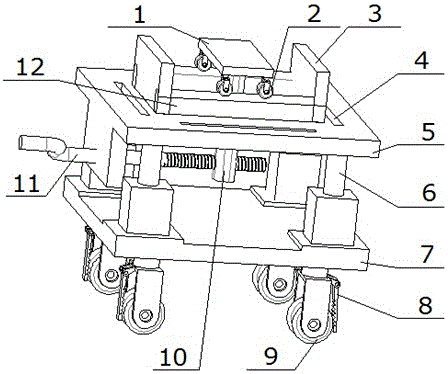

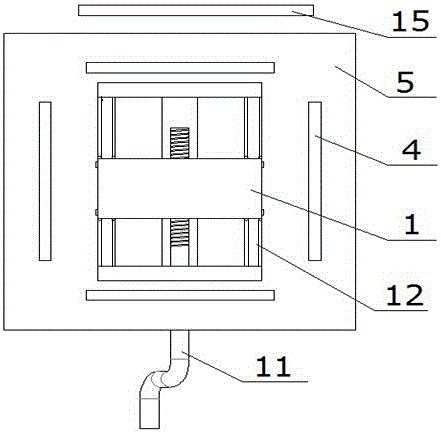

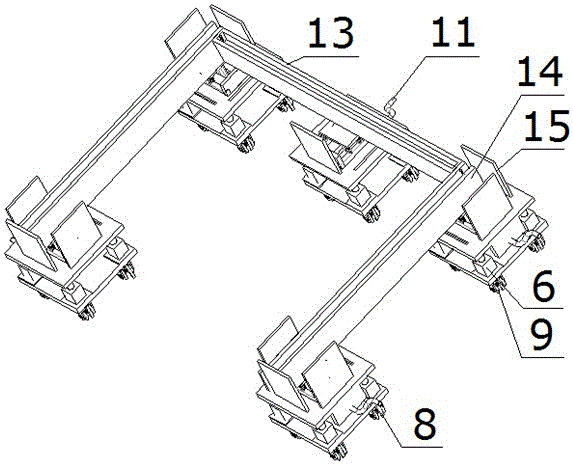

[0021] see figure 1 , a steel truss assembly support adjustment device, the assembly support adjustment device includes a movable platform 1, a fixed base 7, a mobile base 5, an adjustment assembly and a mobile assembly, the mobile base is arranged on the fixed base 7, The moving assembly is arranged under the fixed base, and the adjusting assembly is arranged between the movable platform and the fixed base. The adjusting assembly includes a rail wheel 2, a guide rail 12, a threaded column 10, a threaded rocker 11, two The guide rail 12 is fixedly installed on the mobile base, the support limit plate 3 is fixedly installed on both ends of the guide rail 12, the guide rail wheels are installed under the movable platform 1 and placed on the guide rail 12; the upper end of the threaded column 10 is fixedly installed on the movable platform 1 Below, the lower end is provided with a threaded hole; threaded rocker 11 has one end threaded through the threaded hole at the lower end of...

Embodiment 2

[0023] see figure 1 , figure 2 , as an improvement of the present invention, the number of moving components is four, and the moving components include movable wheels 9 and brake blocks 8, and the brake blocks are arranged on the movable wheels. The movable wheel can make the device move back and forth, and the brake block fixes the device when the device is assembled. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0025] see figure 1 , figure 2 , as an improvement of the present invention, the splicing support adjustment device further includes a support limit plate 3, and the limit plate is installed at both ends of the guide rail 12 to play a position limit function. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com