Sleeve connection device and construction method for lightning protection and grounding of structural steel bars in industrialized buildings

A sleeve connection, lightning protection and grounding technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of inability to form conductive paths, achieve reliable mechanical properties, ensure grouting channels, and increase contact areas. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

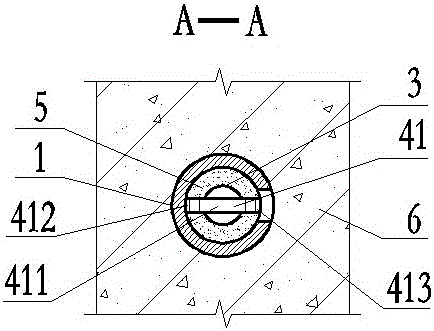

[0039] Such as figure 1 , figure 2 As shown, a sleeve connection device for lightning protection and grounding of structural reinforcement in industrialized buildings includes a grouting sleeve 1, structural reinforcement A2, structural reinforcement B3, metal shrapnel 41, and grouting material 5. One end of the grouting sleeve 1 is connected to the One end of the structural steel bar A2 is threaded or welded, and the two are pre-embedded in the structural member A6, the other end of the grouting sleeve 1 is flush with the end face of the structural member A6, and the structural steel bar B3 is pre-embedded in the structural member B7, And one end protrudes from the end surface of the structural member B7. The metal elastic piece 41 is a strip-shaped inverted V-shaped metal elastic piece 41, which has a connecting portion 411 and free ends 412, 413. The connecting portion 411 is located in the middle section of the belt-shaped inverted V-shaped metal elastic piece. , the fre...

Embodiment 2

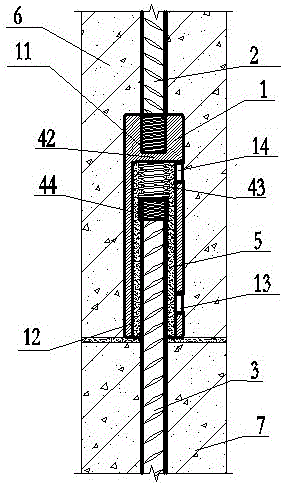

[0050] Such as image 3 As shown, a sleeve connection device for lightning protection and grounding of structural steel bars in industrialized buildings includes a grouting sleeve 1, structural steel bars A2, structural steel bars B3, limiters 42, springs 43, nuts 44, and grouting materials 5. One end of the grouting sleeve 1 is screwed or welded to one end of the structural steel bar A2, and the two are pre-embedded in the structural member A7, and the grouting sleeve 1 is provided with a limiting member 42, and the limiting member 42 is made of a metal material , and integrally processed with the grouting sleeve 1, the other end of the grouting sleeve 1 is flush with the end face of the structural member A7, the structural steel bar B3 is pre-embedded in the structural member B8, and one end protrudes from the end face of the structural member B8 A nut 44 is welded or threaded on one end of the structural steel bar B3 protruding from the structural member B8, and a spring 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com