Method and device for recycling acetylene during production process of vinyl acetate

A vinyl acetate and recovery method technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve problems such as loss of acetylene raw materials, achieve the effects of improving utilization rate, easy implementation, and reducing unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

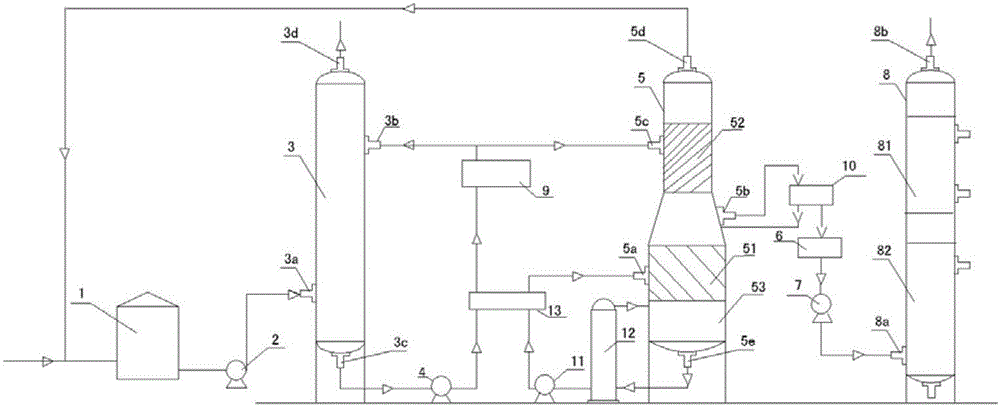

[0039] like figure 1 As shown, the present embodiment first sets up the following recovery device: comprising exhaust gas collection tank 1, first pressurization equipment 2, absorption tower 3, first pump 4, degassing tower 5, recovery gas collection tank 6, second pressurization Equipment 7, water washing tower 8, absorption liquid condenser 9, brine condenser 10, second pump 11, reboiler 12 and heat exchanger 13;

[0040] The absorption tower is sequentially provided with an outlet 3c at the bottom of the absorption tower, an inlet 3a at the bottom of the absorption tower, an inlet 3b at the top of the absorption tower and an outlet 3d at the top of the absorption tower;

[0041] The degassing tower 5 is arranged in three sections, from bottom to top, it is the absorption liquid storage section 53, the degassing tower desorption section 51 and the degassing tower absorption section 52; the bottom of the absorption liquid storage section 53 is the bottom outlet 5e of the deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com