Door distribution system for refrigerator production line

A production line and door body technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve problems such as inaccurate door inventory information, unsuitable boxes and doors, and affect production efficiency, so as to improve delivery The efficiency of storage, the realization of door body informatization, and the effect of improving distribution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

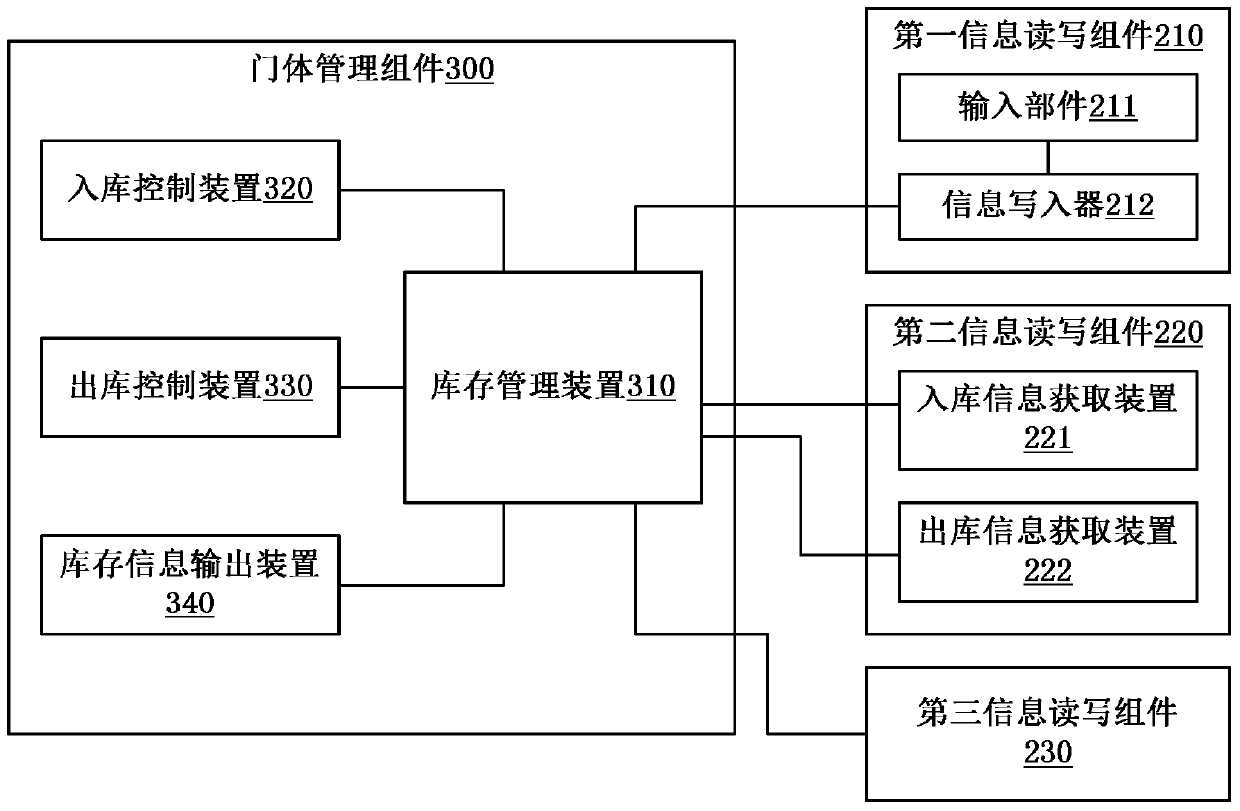

[0028] An embodiment of the present invention provides a door delivery system for a refrigerator production line. figure 1 It is a schematic structure diagram of a door delivery system for a refrigerator production line according to an embodiment of the present invention. The refrigerator door distribution system in this embodiment at least includes: a transmission track 100, a carrying device 110, a first information reading and writing component 210, a second information reading and writing component 220, a third information reading and writing component 230, and a door management component 300( figure 1 not shown).

[0029] The conveying track 100 runs through the door assembly area 10 , the door storage area 20 , and the refrigerator assembly area 30 in the refrigerator production line. A plurality of carrying devices 110 are arranged on the conveying track 100 to be respectively driven to move along the route set in the conveying track 100, and each carrying device 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com