Powder bagging control method

A control method and powder technology, applied in the direction of packaging automatic control, packaging, solid materials, etc., can solve the problems of easy scattering, environmental pollution, affecting packaging quality, etc., and achieve the effect of ensuring environmental quality and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

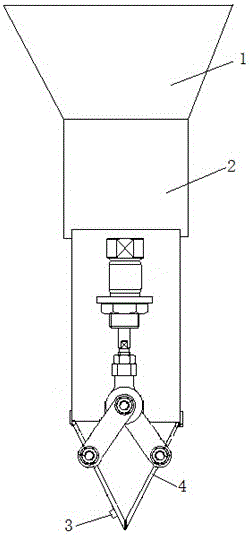

[0010] See figure 1 , a control method for powder bagging, the main controller first controls the telescopic feeding pipe 2 to extend the overall pipe length, when the position sensor 3 senses the packaging bag, the main controller controls the telescopic feeding pipe 2 to stop extending, and then After the main controller controls the bag opening mechanism 4 to start and open the opening end of the packaging bag, the length of the telescopic feeding pipe 2 is extended again, and the extended length is 1 / 5 to 1 / 4 of the height of the packaging bag, and finally the feeding The valve of the bucket 1 is opened, and the powder enters the inside of the packaging bag through the telescopic feeding pipe 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com