Large-scale equipment automatically centering method

A technology for automatic alignment of medium and large equipment, applied in the field of control, can solve the problems of immature technology and much preparation work, and achieve the effect of simple principle, less supporting equipment, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following describes in detail an embodiment of a method for automatic centering of large equipment according to the present invention with reference to the accompanying drawings.

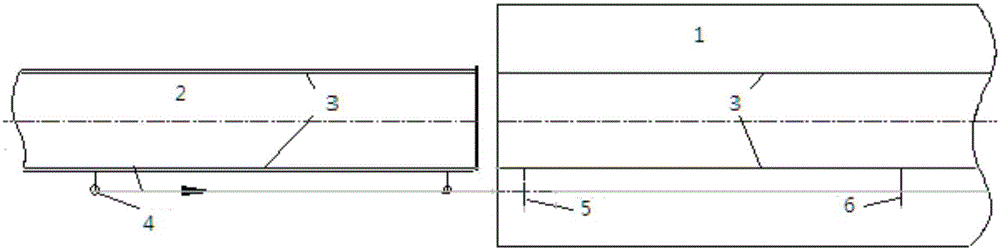

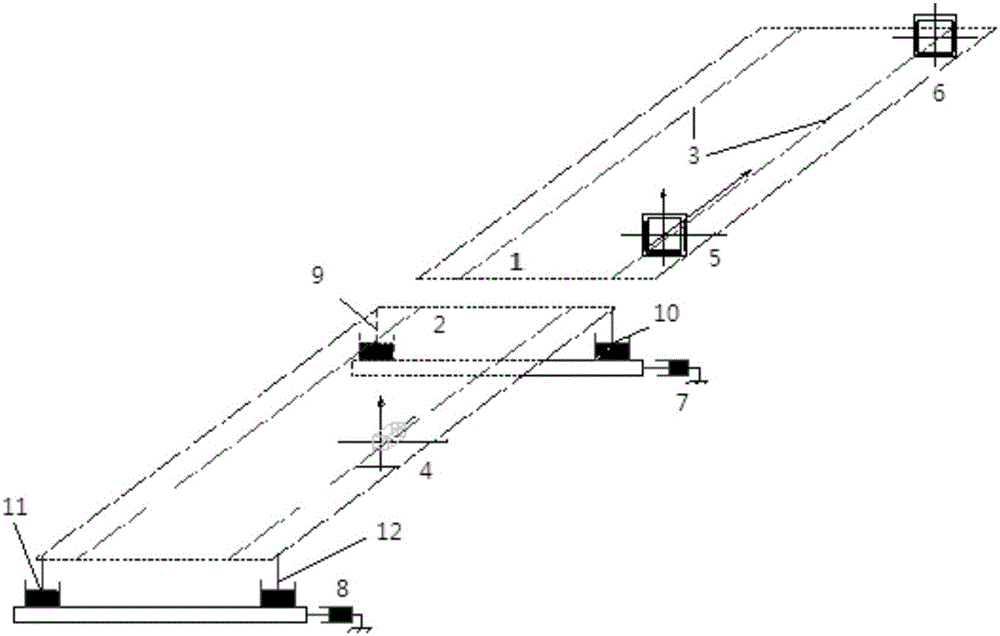

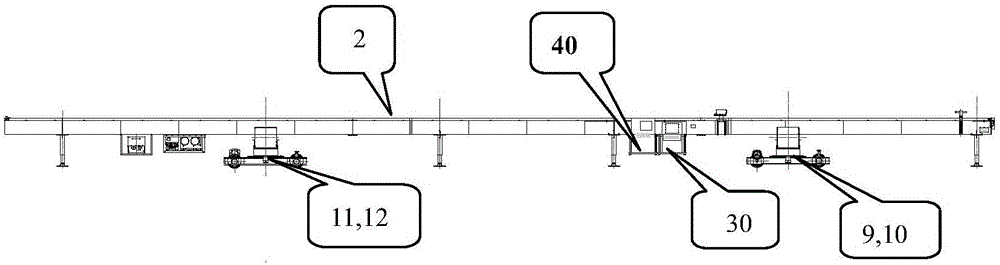

[0027] Such as Figure 1 to Figure 4 As shown, a method for automatic centering of large equipment provided by the present invention applies automatic centering technology, including a measurement system 30, a control system 40 and an adjustment device, so that the centering device 2 has the ability to measure deviations and adjust multiple degrees of freedom. Control ability to complete the posture measurement and alignment adjustment with the target device 1.

[0028] The measurement system 30 includes an observer 4 and front and rear targets 5 and 6. Two targets are installed on the target device 1, and the center line represents the characteristic posture of the target device 1. The observer 4 is installed on the centering equipment 2, and the sight line of the observer is calibrated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com