Soldering machine for manganese-copper terminals

A technology for soldering machines and terminals, which is applied in the direction of tin feeding devices, welding equipment, auxiliary devices, etc., can solve the problems of inaccessibility, inaccurate positioning, instability, etc., achieve reasonable structural design, improve work efficiency, and good soldering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

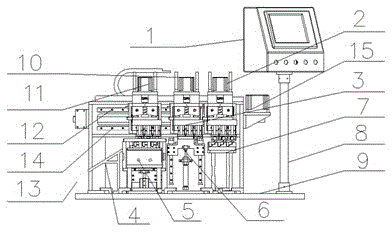

[0013] Such as figure 1 As shown, a manganin terminal soldering machine includes a body 13, the body 13 includes a control box 1, a base 9, a first conveying motor 2 and a second conveying motor 10, and a base 9 is provided under the body 13; The surface of the base 9 is provided with a control box 1; the left side of the control box 1 is provided with an upper rosin workbench 6; the right of the upper rosin workbench 6 is provided with a manual discharging table 7; the upper rosin workbench 6 A first conveying motor 2 is provided above; a second conveying motor 10 and a third conveying motor 11 are respectively provided on the left side of the first conveying motor 2; and the first conveying motor 2, the second conveying motor 10 and the third conveying motor The output part of the conveying motor 11 is connected with a conveying mechanism 3; a soldering furnace 5 is provided on the left side of the upper rosin worktable 6; a buffer rail is provided above the soldering furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com