Bending mechanism of aluminum strip bending machine

A bending mechanism and bending machine technology, applied in the field of aluminum bending, can solve problems affecting the life and quality of insulating glass, low degree of automation, poor rigidity of aluminum frames, etc., to achieve small error, high degree of automation, and good rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

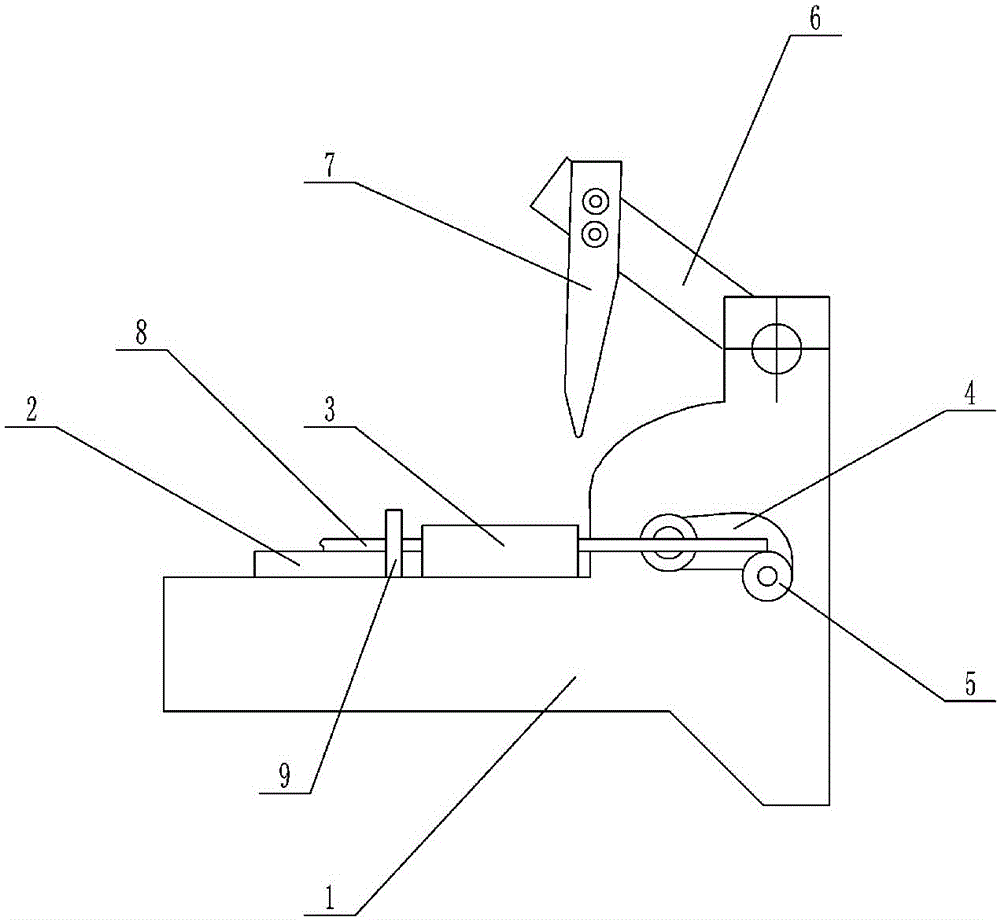

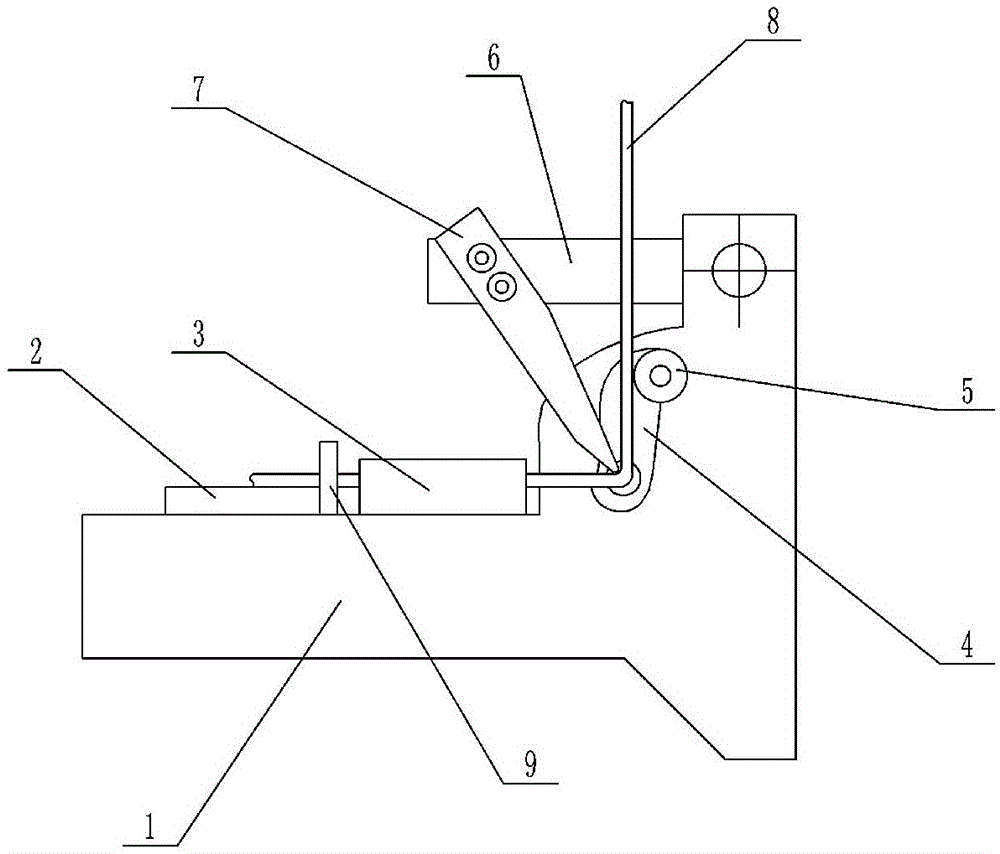

[0017] The reference signs in the accompanying drawings of the specification include: frame 1, support block 2, guide plate 3, bending block 4, guide wheel 5, strut 6, pressing bar 7, aluminum bar 8, displacement sensor 9.

[0018] Such as figure 1 As shown, the bending mechanism of the aluminum strip bending machine includes a frame 1, a support block 2, a displacement sensor 9, a controller, a bending block 4, a first servo motor, a support rod 6, a pressure rod 7 and a second servo motor. The motor, the support block 2 is welded on the frame 1, the displacement sensor 9 is installed on the frame 1, and is located on the side of the support block 2, the bending block is 7-shaped, and the bending block 7 is installed on the output shaft of the first servo motor superior. The guide wheel 5 is rotatably installed on the bending block 7, and one end of the pole 6 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com