Industrial distillation still facilitating pouring-out

A distillation kettle and industrial technology, applied in the field of industrial distillation equipment, can solve the problems of high labor intensity and low efficiency of obtaining distillation products, and achieve the effects of reducing labor costs, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail below by specific embodiments:

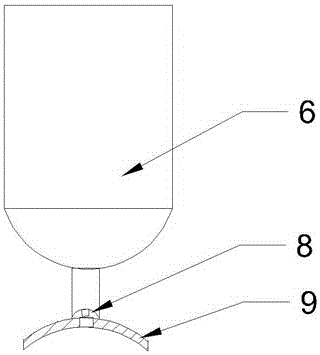

[0013] Reference numerals in the accompanying drawings include: kettle body 1, frame 2, clamping member 3, rotating shaft 4, first air cylinder 5, second air cylinder 6, infrared transmitter 7, infrared receiver 8, arc pusher plate 9.

[0014] The example is basically as attached figure 1 , figure 2 Shown: an industrial distillation kettle that is easy to pour, including a kettle body 1 and a frame 2, including a fixing mechanism and a control mechanism, the fixing mechanism includes a clamping member 3, and the kettle body 1 is fixedly installed with a sheath on the upper circumference, and the clamp The holder 3 is fixedly connected to the kettle body 1 by means of bolts. The width of the holder 3 is between 1 / 4-1 / 3 of the length of the kettle body 1. If the width of the holder 3 is less than 1 / 4 of the length of the kettle body 1, the effect of the holder 3 on the kettle body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com