Adjustable shoe material rack

An adjustable and shoe-material technology, applied to footwear, shoe-making machinery, clothing, etc., can solve the problems of lower shoe-making efficiency, limited load-bearing area, and increased number of pallet layers, so as to improve shoe-making efficiency and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

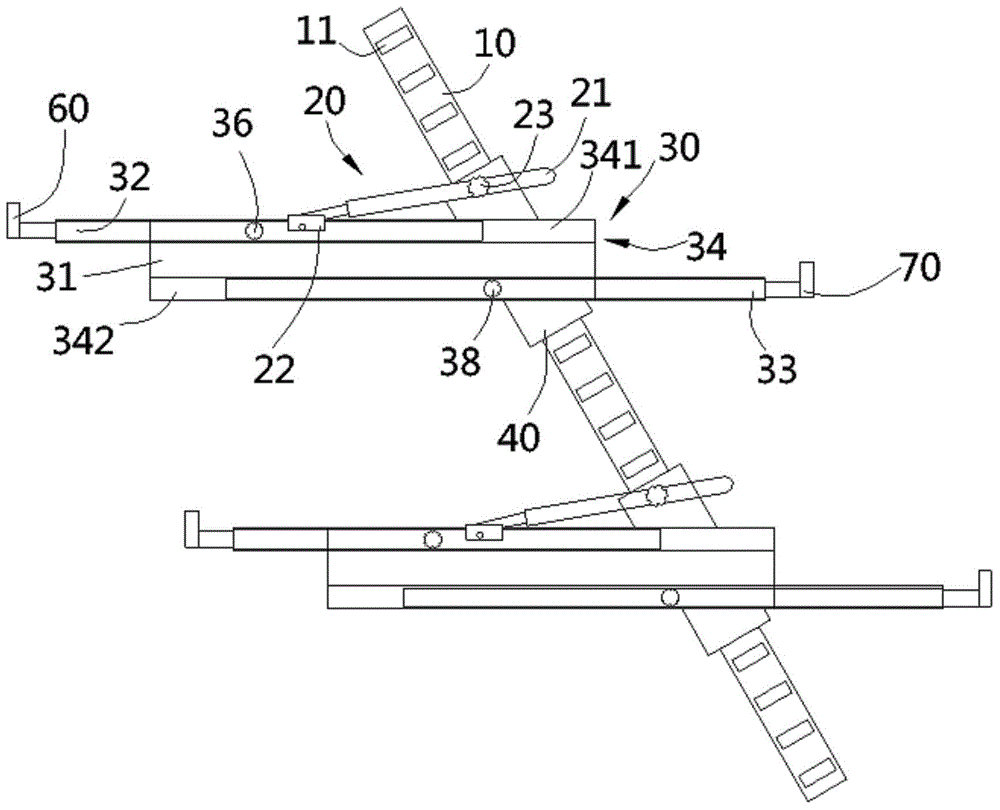

[0022] see figure 1 , a kind of adjustable shoe material placement shoe rack according to the present invention, comprises two inclined supporting columns 10, several groups of tray brackets 20 fixed on the said supporting columns and fixed on each group of tray brackets Several pallets 30 fixed on the support column 10;

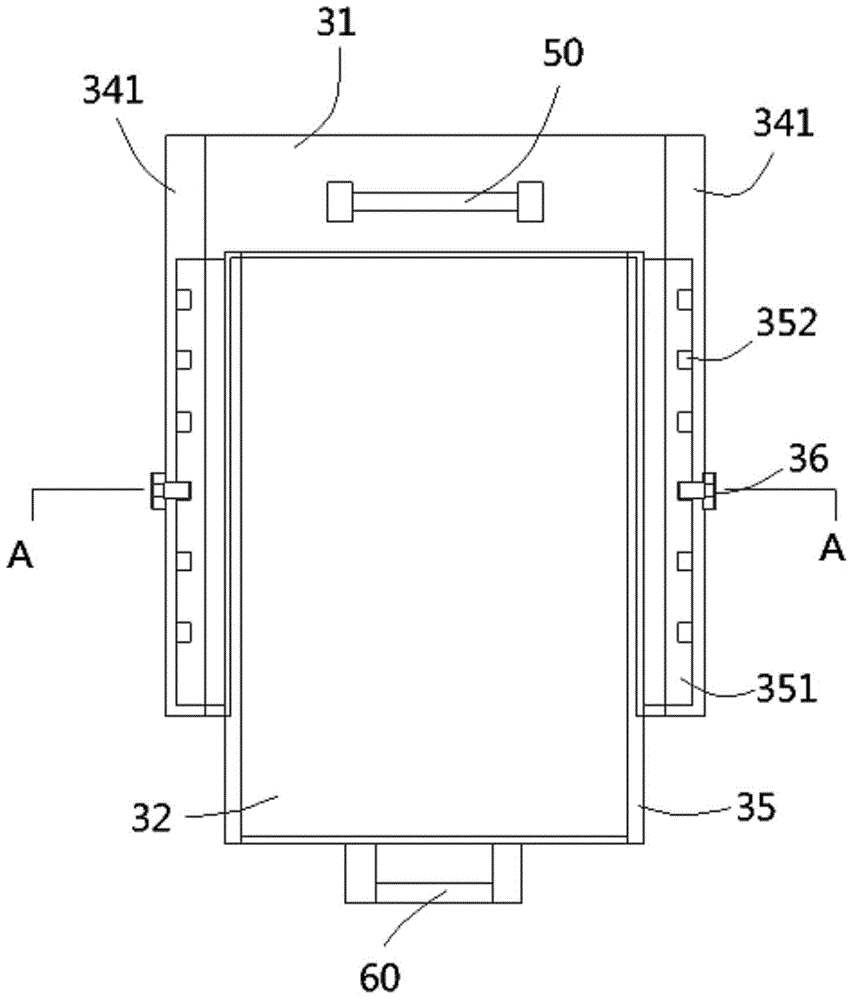

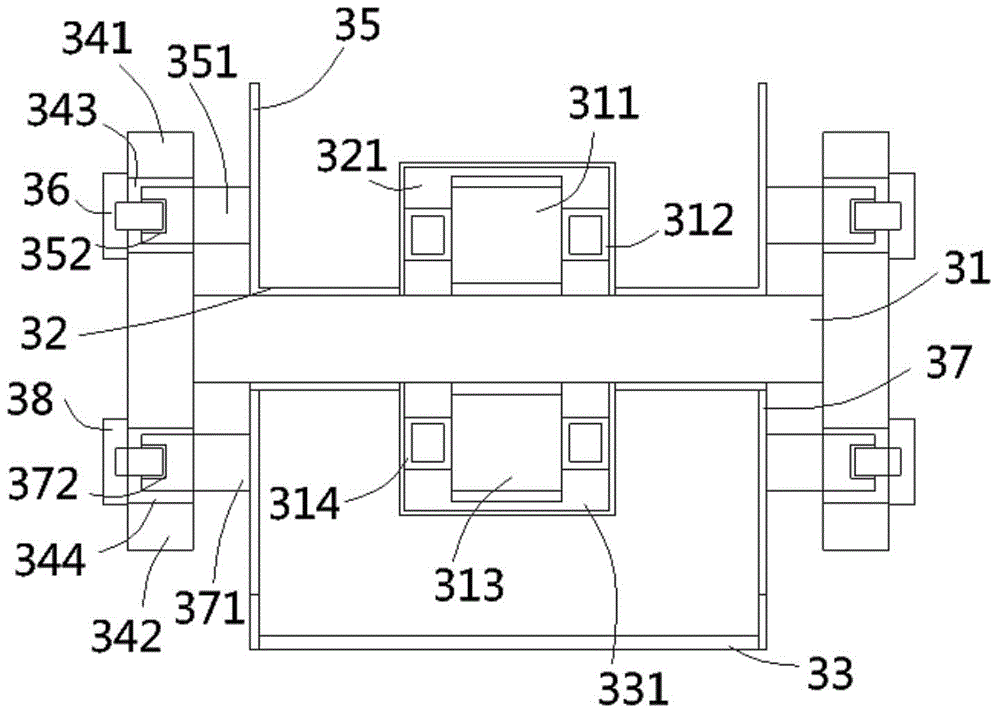

[0023] see Figure 1 to Figure 3 , the tray 30 includes a base plate 31, an upper adjustment plate 32 arranged above one side of the base plate and a lower adjustment plate 33 arranged under the other side of the base plate, and two surrounding plates are formed on the left and right sides of the base plate 31 34. The upper and lower end surfaces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com