Friction plate and wet multi-plate clutch provided with friction plate

一种摩擦片、离合器的技术,应用在湿式多片离合器领域,能够解决拖曳转矩变大、拖曳转矩大、不容易排出等问题,达到提高冷却效率、降低效果好、降低拖曳转矩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

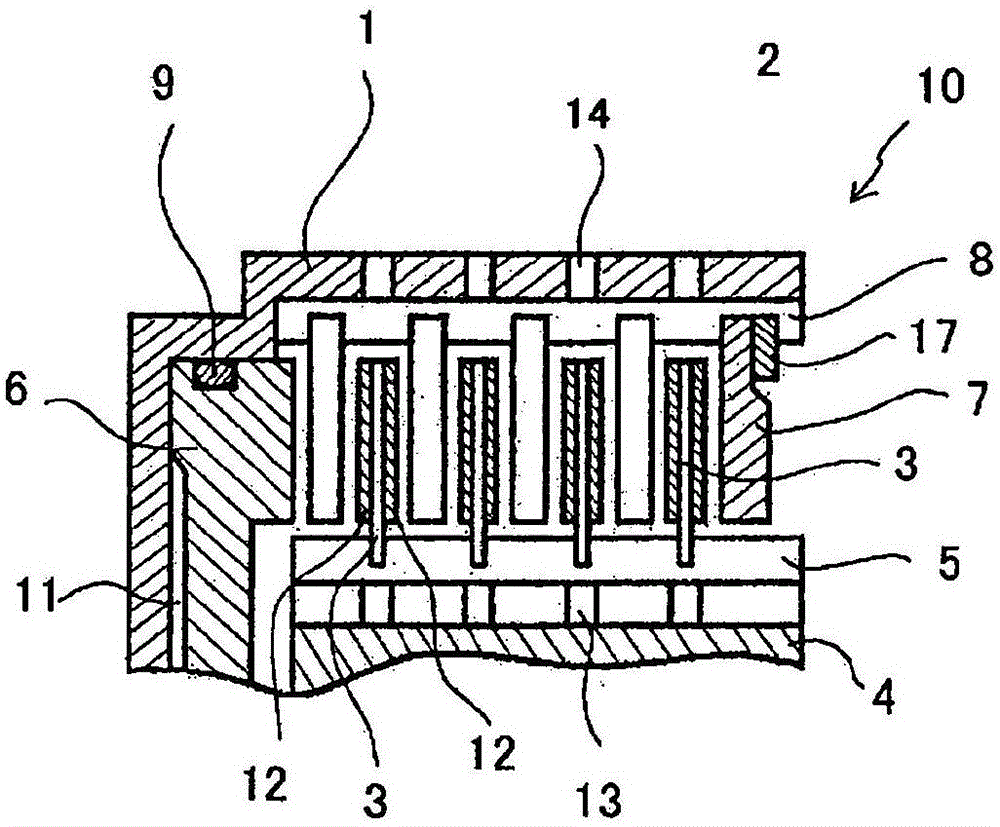

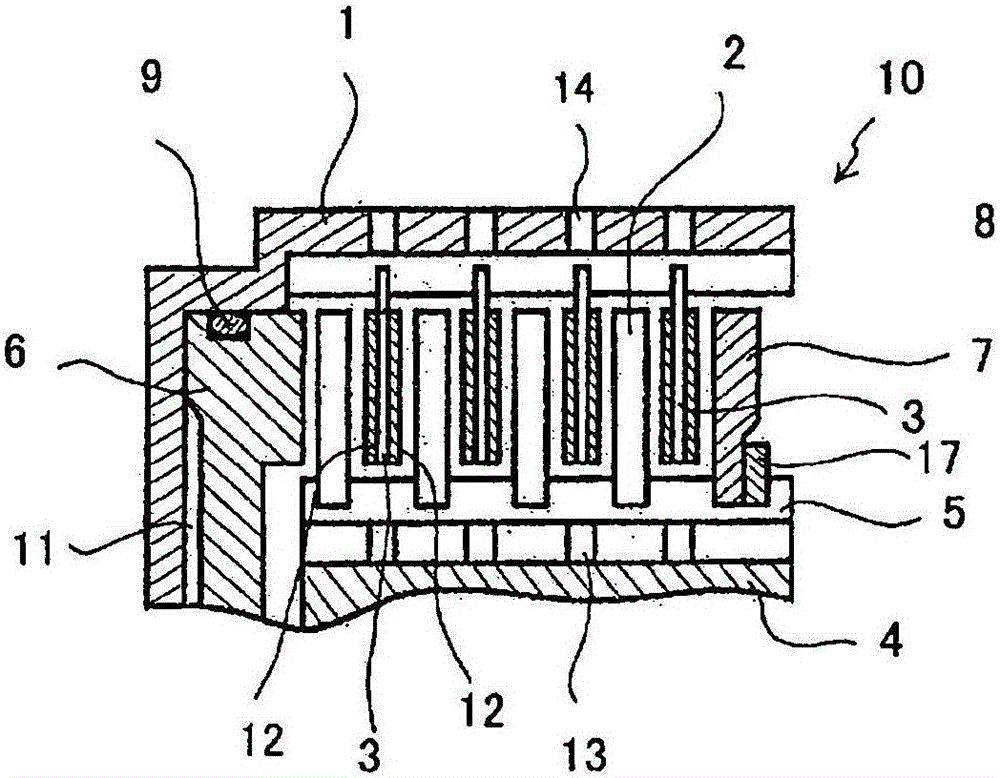

[0054] image 3 It is a partial front view of the friction plate 3 showing the first embodiment of the present invention. The friction sheet 3 has a friction surface 25 formed by attaching a plurality of friction material segments 21 arranged substantially equally in the circumferential direction with an adhesive or the like on a substantially annular core plate 20 . The core plate 20 has splines 20 a engaged with the splines 5 of the bushing 4 on the inner periphery.

[0055] Such as image 3 As shown, one friction material segment 21 is provided with an oil groove 23 having an opening 23a opening in the direction of the outer periphery 27 of the friction plate 3 and a closed end 23b terminating between the inner and outer periphery. One oil groove 23 not penetrating in the inner diameter direction is provided on the friction material segment 21 .

[0056] A gap having a predetermined circumferential width is provided between adjacent friction material segments 21 . At th...

no. 2 example

[0064] Figure 4 It is a partial front view of the friction plate 3 showing the second embodiment of the present invention. In the second embodiment, the shapes of the friction material segments attached and fixed on the core plate 20 are different. In the second embodiment, friction material segments of two shapes are fixed to the core plate 20 as in the first embodiment. The friction material segment 31 has an opening 33 a that opens toward the outer peripheral edge of the friction sheet 3 , and a closed end 33 b that ends between the inner and outer peripheral edges. The radial length of the oil groove 33 is 1 / 2 or more of the radial width of the friction material segment 31 . Therefore, the end portion 33b of the oil groove 33 exceeds half of the width in the radial direction and is located at a position deviated to the radially inner side.

[0065] From Figure 4 It can be seen that the oil groove 33 is arranged to deviate from one end 35 of the friction surface 25 of t...

no. 3 example

[0081] Figure 5 It is a partial front view of a friction plate showing a third embodiment of the present invention. The third embodiment is a modified example of the second embodiment. The structures of the friction material segment 31 and the friction material segment 32 are the same as those of the second embodiment. In the third embodiment, between a pair of friction material segments composed of adjacent friction material segments 31 and 32 , a friction material block 50 not provided with an oil groove is disposed.

[0082] Such as Figure 5 As shown, the friction material block 50 is not formed with the oil grooves opening in the outer peripheral direction that the friction material segments of the first embodiment and the second embodiment have. The friction material block 50 has a shape in which the width in the circumferential direction becomes smaller from the outer diameter portion 50a toward the inner diameter portion 50b. Therefore, if the friction material bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com