Optimization method for underground single-hole drainage of high-pressure coal seam floor water

A coal seam floor and optimization method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high total drainage and failure to achieve optimization goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

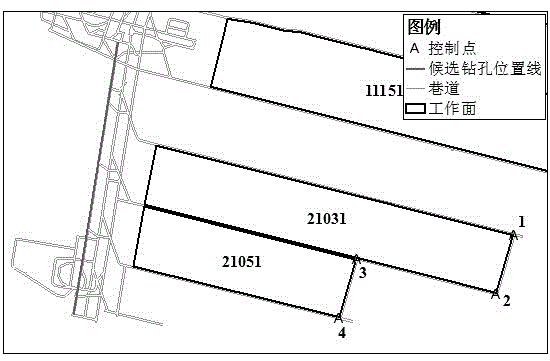

[0068] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

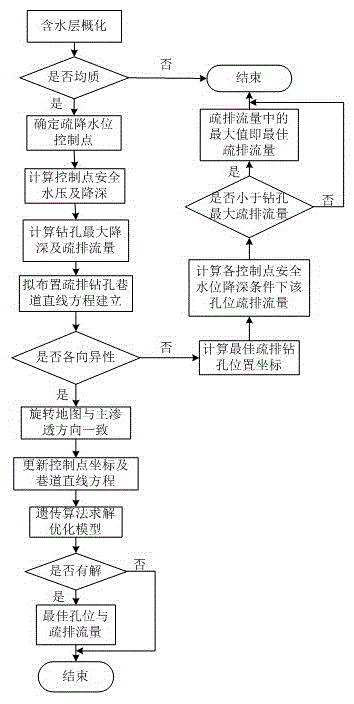

[0069] Such as figure 1 As shown, the coal seam floor high pressure water underground single hole dredging optimization method of the present invention comprises the following steps:

[0070] a. Data Collection and Aquifer Generalization:

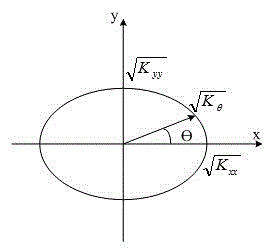

[0071] Collect geological, hydrological, and exploration information of the mining area, and generalize the hydrogeological conditions of the dewatering area according to the collected information, that is, simplify or reduce the actual boundary characteristics, internal structure, permeability, hydraulic characteristics, and path-filling conditions of the aquifer. Abstract; according to the existing well-known permeability coefficients obtained from borehole pumping tests in different geographic locations, compare whether there are significant differences in the conductivity values of the aquifers to be dredged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com