Differential current measuring module

A technology for measuring components and differential currents, applied to electrical components, measuring devices, measuring electrical variables, etc., can solve problems such as expensive and unfavorable differential current measuring equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

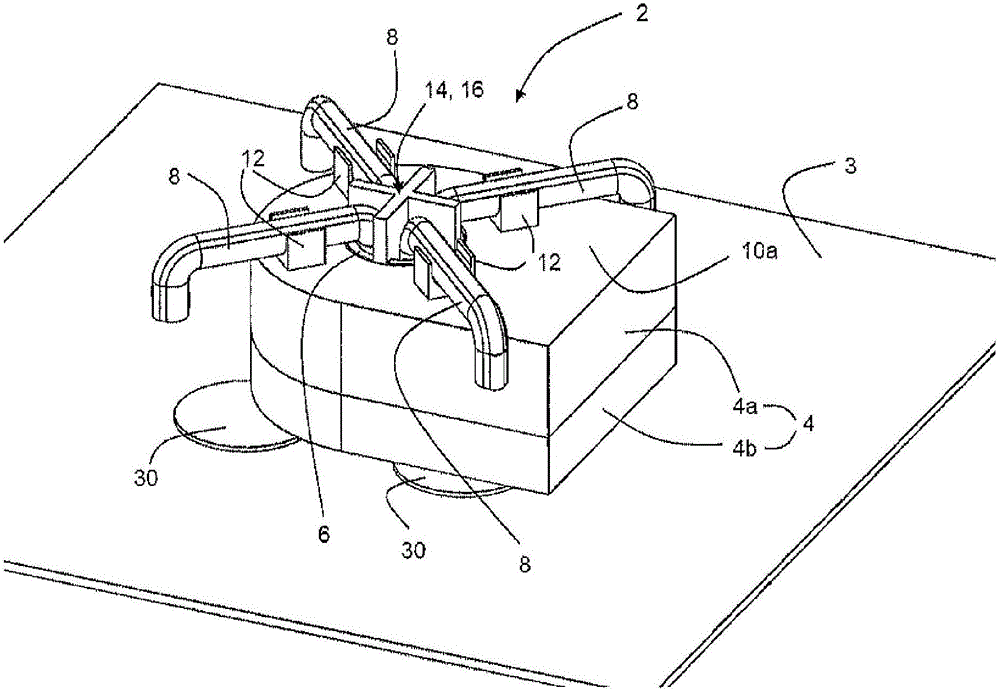

[0048] figure 1 An external view of a differential current measuring assembly 2 according to the invention is shown, which is mounted on a printed mounting board 3 . The differential current measurement assembly 2 is an integrated assembly for differential current measurement which can be equipped with a printed mounting board 3 .

[0049] In the embodiment example shown, the differential current measurement assembly 2 consists of a split housing 4 with an upper housing part 4a and a lower housing part 4b. The housing 4 has a cylindrical conduit 6 in which four primary conductors 8 are arranged as part of the differential current measuring assembly 2 .

[0050] The four primary conductors 8 thus form a line section through which the feeder to be monitored with three phase conductors (L1, L2, L3) and a neutral conductor (N) runs in the conduit 6 for registering differential currents .

[0051] Furthermore, in single-phase or two-phase power supply systems with high current l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com