Method for measuring detonation pressure of explosive in blast hole

A measurement method and technology of detonation pressure, applied in the direction of measuring blasting force, etc., to achieve the effect of improving reliability, reliable test results, and suitable for large-dose testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

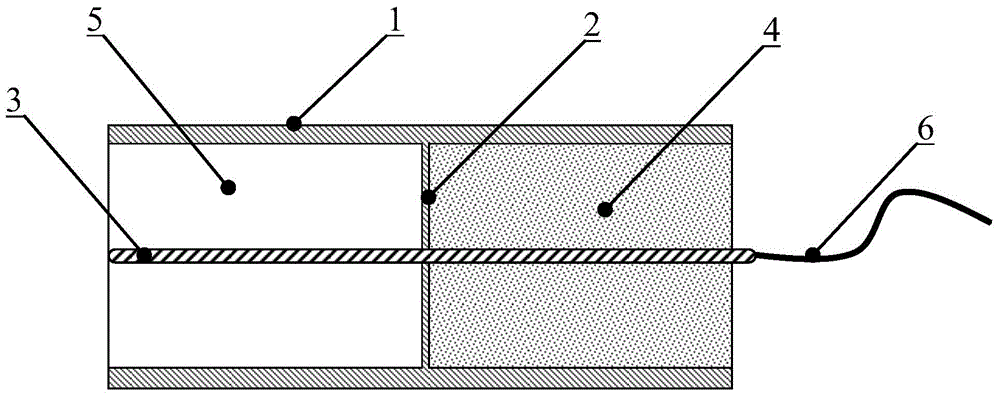

[0027] ①Prefabrication of the explosion pressure lumped sensor 7: take a PVC plastic pipe with a diameter of 110mm and a wall thickness of 3.0mm as the cylindrical shell container 1, in which the length of the charge section is 200mm, the length of the contrast medium section is 292mm, the contrast medium 4 is paraffin, and the continuous resistance wire probe The total length of the needle 3 is 492.5 mm, and the total resistance is 275 ohms. The calculated resistivity of the resistance wire probe per unit length is 275 Ω / 492.5 mm=0.5584 Ω / mm. First use a plastic sheet as the partition 2, fix the continuous resistance wire probe 3 on the central axis of the PVC pipe, then melt the paraffin, cast it in the 4th section of the contrast medium reserved at the 6 places at the end of the PVC pipe probe, and wait for the paraffin to solidify Remove the plastic partition 2, and measure the paraffin wax density as ρ W0 =0.88g / cm 3 , compared to its theoretical density of 0.917g / cm 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com