Serialized multidimensional deformation data collection device

A data acquisition and serialization technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of incomplete function and small monitoring range, and achieve the effect of compact structure, good effect and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

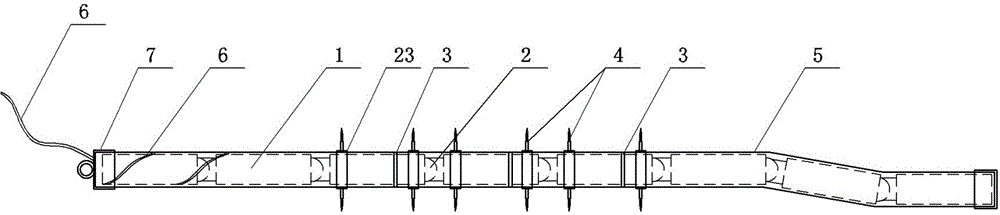

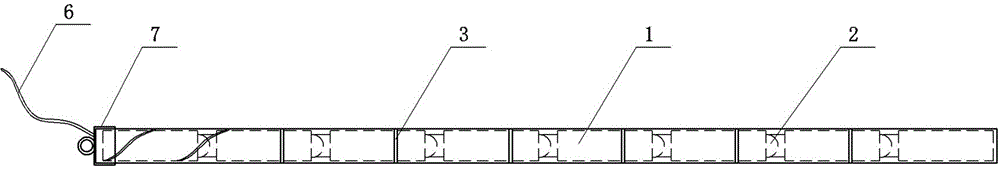

[0032] Embodiment 1: The first serialized multi-dimensional deformation data collection device (SerializedDeformationDataCollector or SDDC), see figure 1 , multiple short joints 1 are connected by universal joints 2 to form a test strip that can be bent arbitrarily, and the short joints 1 can use PVC short pipes or pipe fittings made of other materials, or special solid rods. A flexible outer sleeve 5 is sheathed on the outer side of the arbitrary curved test strip. And it is waterproof and airtight.

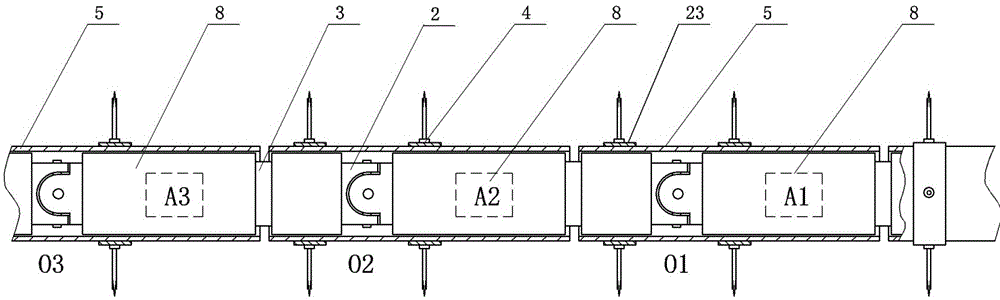

[0033] see image 3, embed bidirectional MEMS sensors 8 and power sources in all short joints 1 or part of short joints 1, and the signal lines of each bidirectional MEMS sensor 8 are collected in the cable 6 and then connected to the wireless transmission device. MEMS (MicroelectroMechanicalSystems) is a new type of sensor manufactured by microelectronics and micromachining technology. Compared with traditional sensors, it has the characteristics of small size, light weight,...

Embodiment 2

[0040] Embodiment 2: The second serialized multi-dimensional deformation data acquisition device. On the basis of Embodiment 1, the rotating parts are improved, such as Figure 5 As shown, the rotating part is provided with a telescopic slot 9 at the end of the pup joint assembly 1a, and a slider 10 is provided at the end of the pup joint assembly 2 1b. A positioning groove 12 is arranged at the center of the inner wall of the telescopic groove 9 , and a positioning ring 13 is arranged on the outer wall of the slider 10 , and the positioning ring 13 cooperates with the positioning groove 12 for positioning. Under normal circumstances, it can be ensured that puppet assembly one 1a and puppet assembly two 1b are neither stretched nor compressed. The flexible outer sleeve 5 is sealed and fixed on the surface of the pup joint at the position of the rotating part.

Embodiment 3

[0041] Embodiment 3: The third serialized multi-dimensional deformation data acquisition device, on the basis of Embodiment 1, improves the positioning mechanism 4 and designs it as a movable positioning mechanism 4 . like Figure 7 and Figure 8 As shown, the fixed bracket 24 is set on the outer side of the flexible outer sleeve 5, and the positioning mechanism 4 is provided with a guide groove inside the fixed bracket 24. A toothed positioning fork 4c is matched and installed in the guide groove, and a rack 19 is provided on its side. , and a ring gear 25 is installed in the center of the pup joint assembly 1a or pup joint assembly 2 1b, the ring gear 25 is engaged with the rack 19 for transmission, and the ring gear 25 is installed on the motor shaft.

[0042] In addition, a supporting sleeve 22 is fitted on the outer side of the tooth type positioning fork 4c. After the formation is drilled, the detection strip is inserted into the drilled hole, and each tooth type posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com