Serial sequential segmental deformation monitoring sensor device

A deformation monitoring and sensing device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of small monitoring range and incomplete function, and achieve the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

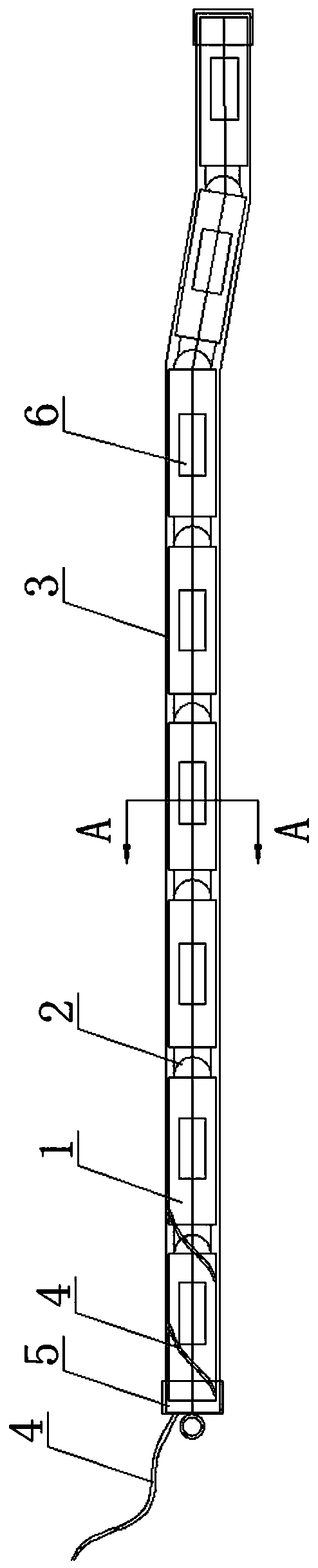

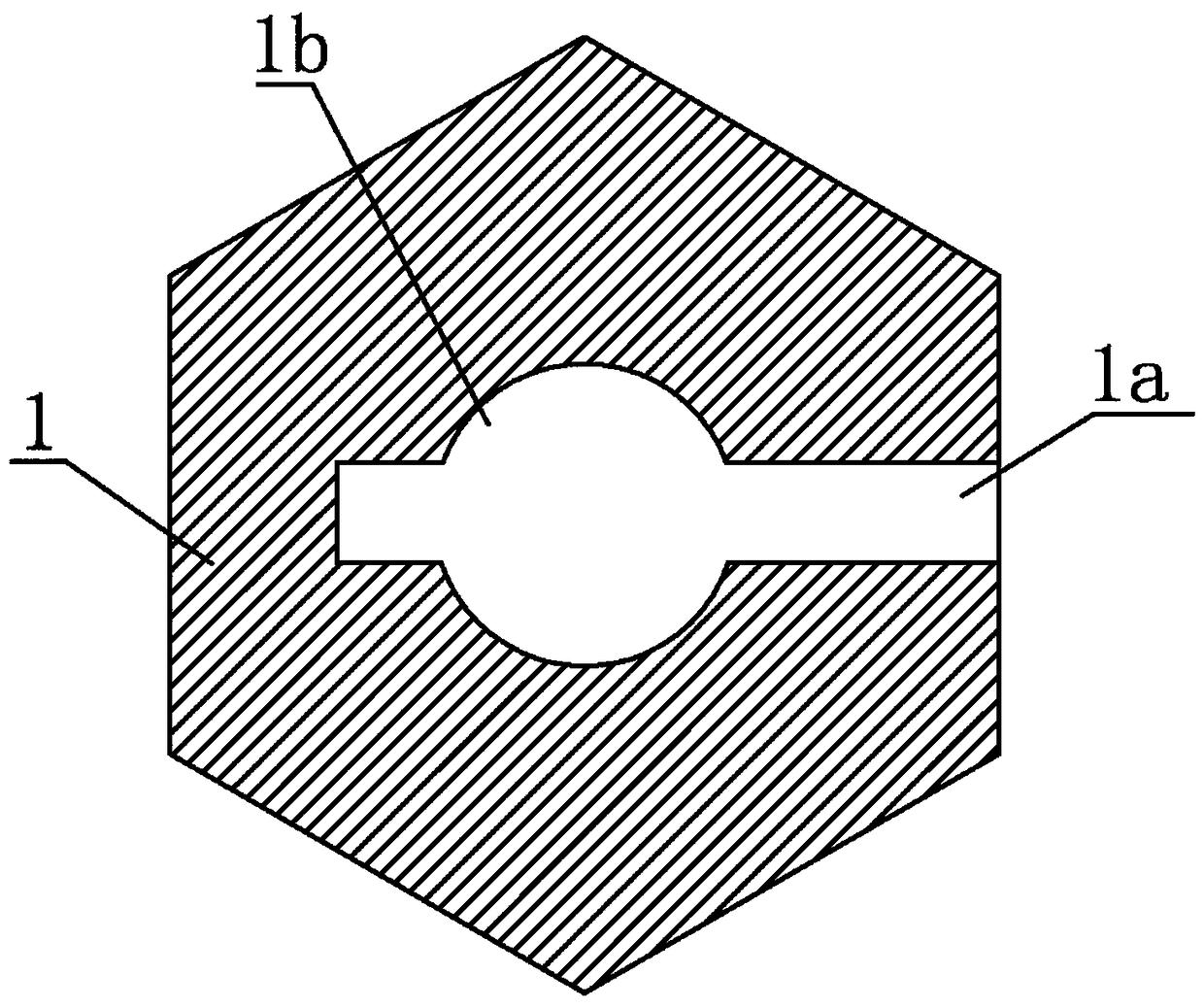

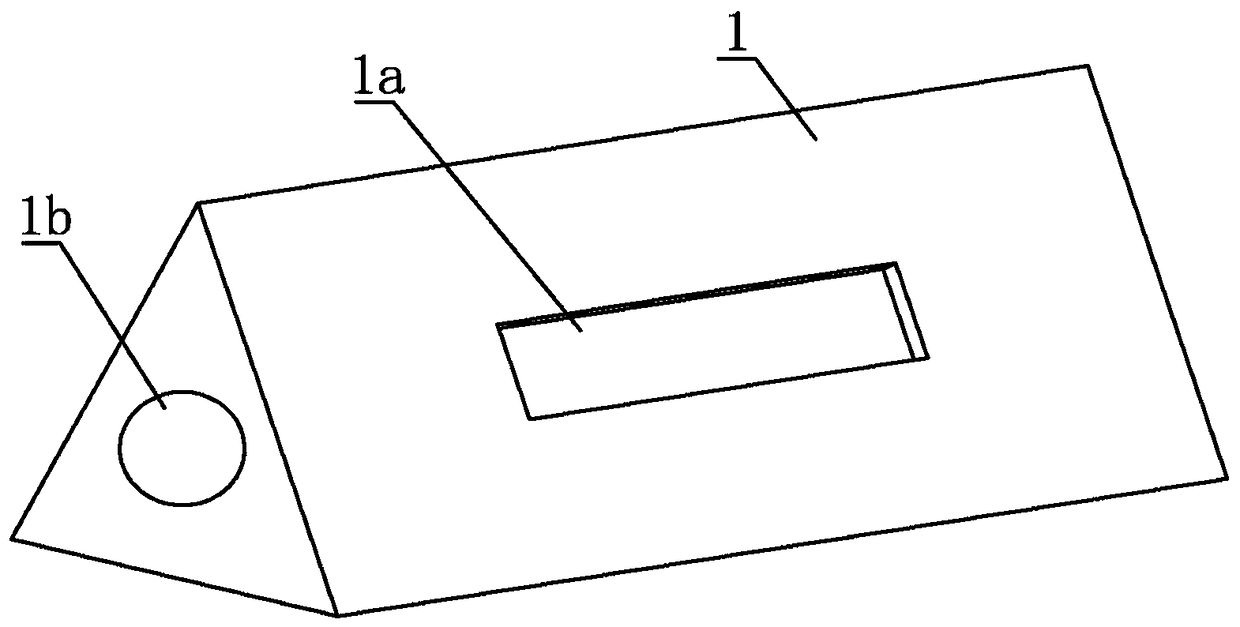

[0031] Embodiment 1: A serial serial segment deformation monitoring sensor device (Serialized Deformation Data Collector or SDDC), see Figure 1-5 , a plurality of unit sections 1 are connected by a universal joint 2 to form a test strip that can be bent arbitrarily, and the main body of the unit section 1 is a triangular prism. Due to the large length range of the unit section, the longer unit section is half a meter to several meters long, and the cylindrical unit section itself is weak in bending resistance, and it is easy to affect the detection data due to its own deformation. In the present invention, the main body of the unit section is set as a triangular prism, which can obviously improve the bending resistance strength.

[0032] The triangular prism is provided with a central hole 1b, and one side of the triangular prism is provided with an installation groove 1a, the depth of the installation groove 1a is larger than the diameter of the central hole 1b; the installa...

Embodiment 2

[0038] Embodiment two: see Image 6 , the second serial serial segment deformation monitoring sensor device, on the basis of the first embodiment, the universal joint 2 is improved, and the N limit holes 2f are arranged crosswise along the axial and radial directions of the shaft tube 2a. This arrangement makes it more precise to adjust the angle of the universal joint.

Embodiment 3

[0039] Embodiment three: see Figure 7-8 , the third serial serial segment deformation monitoring sensing device, on the basis of the first embodiment, the unit section 1 is improved, the installation groove 1a in the third embodiment is larger than the opening size of the installation groove 1a in the first embodiment, The installation groove 1a is fitted with an elastic cover plate 1c, and the elastic cover plate 1c is clamped in the installation groove 1a through the tongue 1d provided at the front end. The effect of unit section 1 strength is minimized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com