Assembly used for protecting and dismounting high-speed input shaft and output shaft

A technology of input shaft and output shaft, which is applied in the field of high-speed shaft protection, can solve the problems of long time for bearing clearance adjustment, fast wear of the outer circle of the journal, and delay in production time, so as to eliminate oil leakage, prolong the working cycle, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

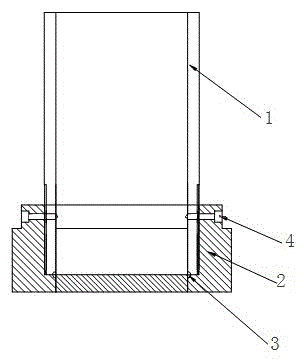

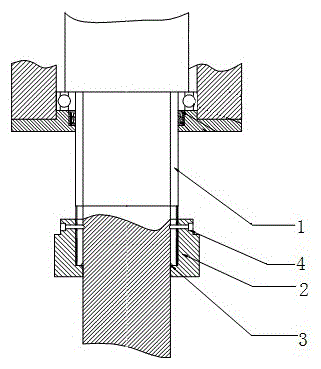

[0030] An assembly for protecting and dismounting high-speed input and output shafts , including hollow protective sleeve 1, special nut 2, O-ring 3 and anti-loosening screw 4.

[0031] The material of the hollow protective sleeve 1 is bearing steel, and the surface of the hollow protective sleeve 1 is evenly provided with fastening screw holes along its radial direction; the special nut 2 is connected with the external thread of the hollow protective sleeve 1, and a circle of concave holes is provided on the inner side of the bottom. Groove; the outside of the top is provided with a circle of inward step surface; the O-ring 3 is co-located in the groove; the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com