Coordinated control method for clutch combination of hybrid power system

A hybrid power system and coordinated control technology, applied in the field of hybrid hybrid power system clutch combined with coordinated control, can solve the problems of large steady-state error and dynamic error, long speed adjustment time, and inability to reduce battery charge and discharge current, etc. Achieve the effect of reducing the charging and discharging current and preventing the temperature from rising too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

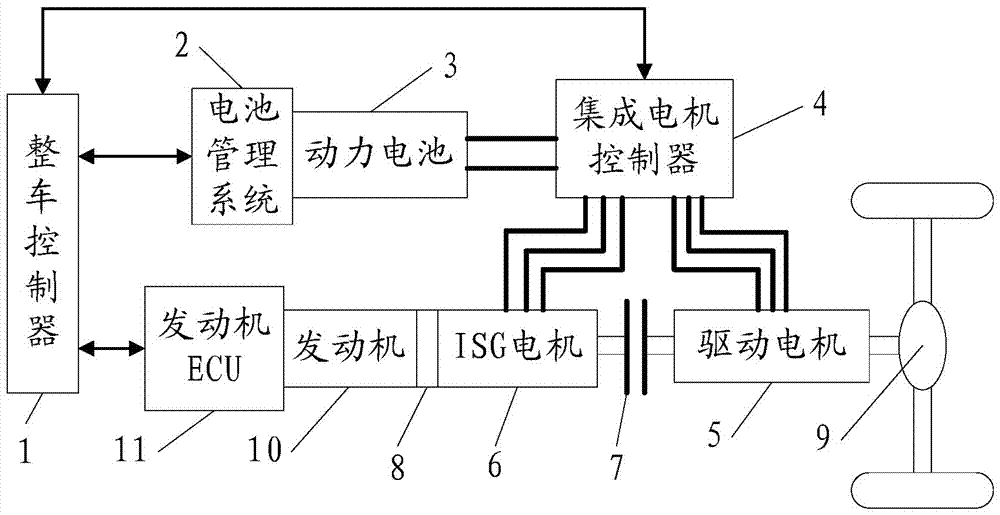

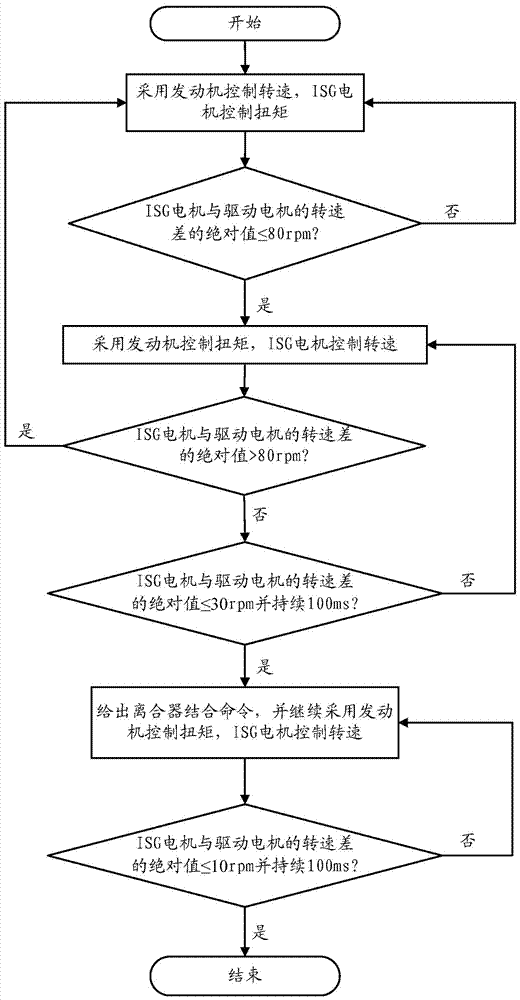

[0021] Please refer to figure 1 and figure 2 As shown, a clutch combination coordinated control method of a hybrid hybrid power system includes the following steps:

[0022] Step 10, before the clutch 7 is combined, first use the engine 10 to control the speed, and the ISG motor 6 to control the torque (during implementation, the vehicle controller 1 sends the torque control command to the integrated motor controller 4 and the engine ECU 11 sends the speed control command respectively , and the torque of the ISG motor 6 is controlled by the integrated motor controller 4, and the speed of the engine 10 is controlled by the engine ECU11); the engine 10, the torsional shock absorber 8, the ISG motor 6, the clutch 7 and the drive motor 5 are connected in sequence and coaxially distributed , wherein, the engine 10 adjusts the speed with the current speed of the drive motor 5 as the target speed to reduce the speed difference between the engine 10 and the drive motor 5; and if the...

specific Embodiment 2

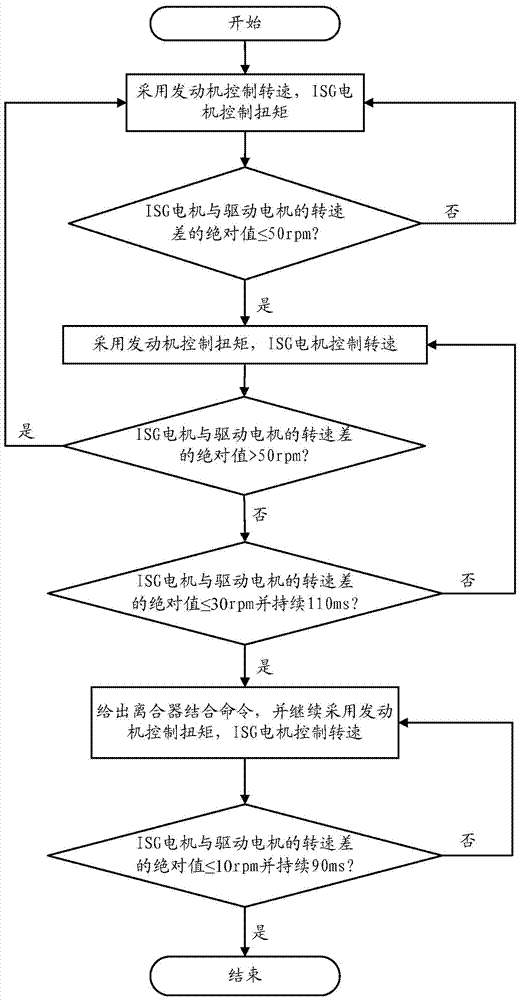

[0027] see figure 1 and image 3 As shown, the difference from the first embodiment is that the value of n0 is 50 rpm, the value of T1 is 110 ms, and the value of T2 is 90 ms.

specific Embodiment 3

[0028] see figure 1 and Figure 4 As shown, the difference from the first embodiment is that the value of n0 is 100 rpm, the value of T1 is 90 ms, and the value of T2 is 110 ms.

[0029] In a word, the present invention can achieve the following beneficial effects: 1. The speed difference between the ISG motor and the drive motor can be controlled within a certain range as soon as possible before the clutch is engaged, so that the time from engine idling up to before the clutch is engaged is less than 1.5 s, the time from high-speed power generation to down-speed adjustment to clutch engagement is less than 2s; 2. Under the premise of realizing normal functions, the charging and discharging current of the battery can be reduced as much as possible to prevent the battery from heating up too quickly or even overheating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com