Flexible clamping device for cylindrical cabin butt assembly

A flexible clamping and cylindrical technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of low efficiency and poor adaptability of cylindrical compartment positioning and clamping devices, and achieve good adaptability, flexible use, and satisfaction The Effect of Accuracy Requirements and Automation Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

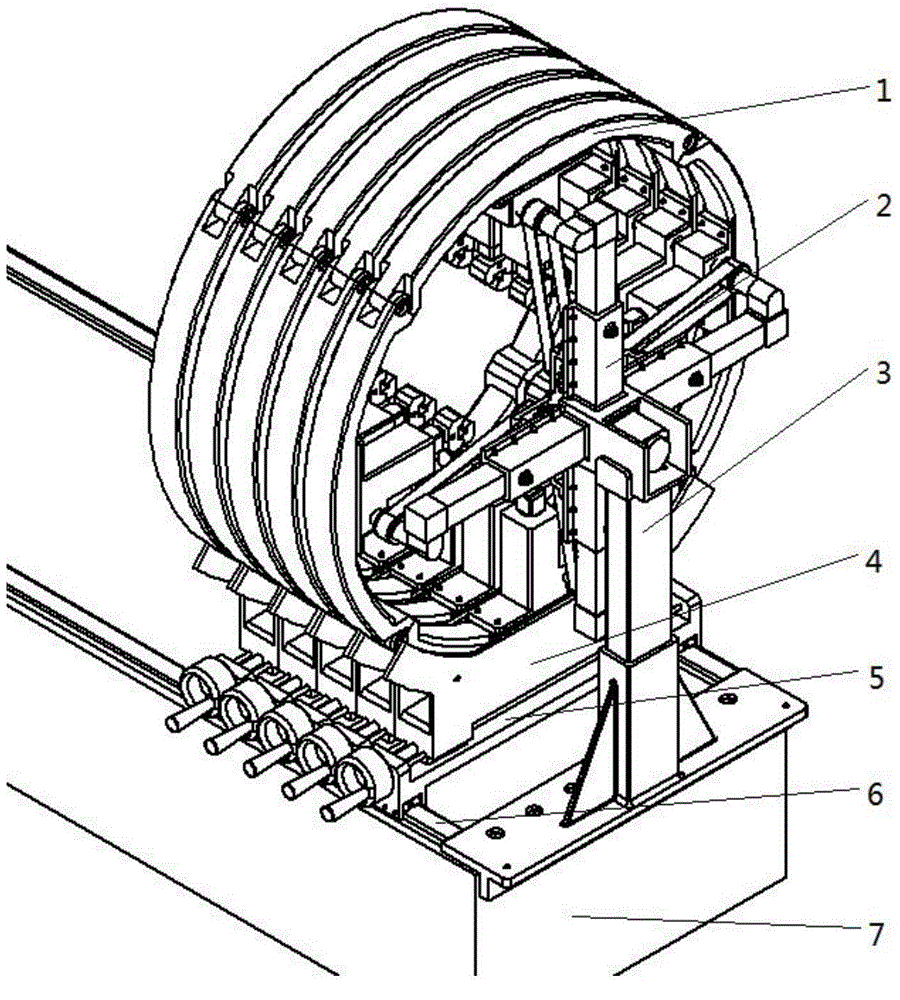

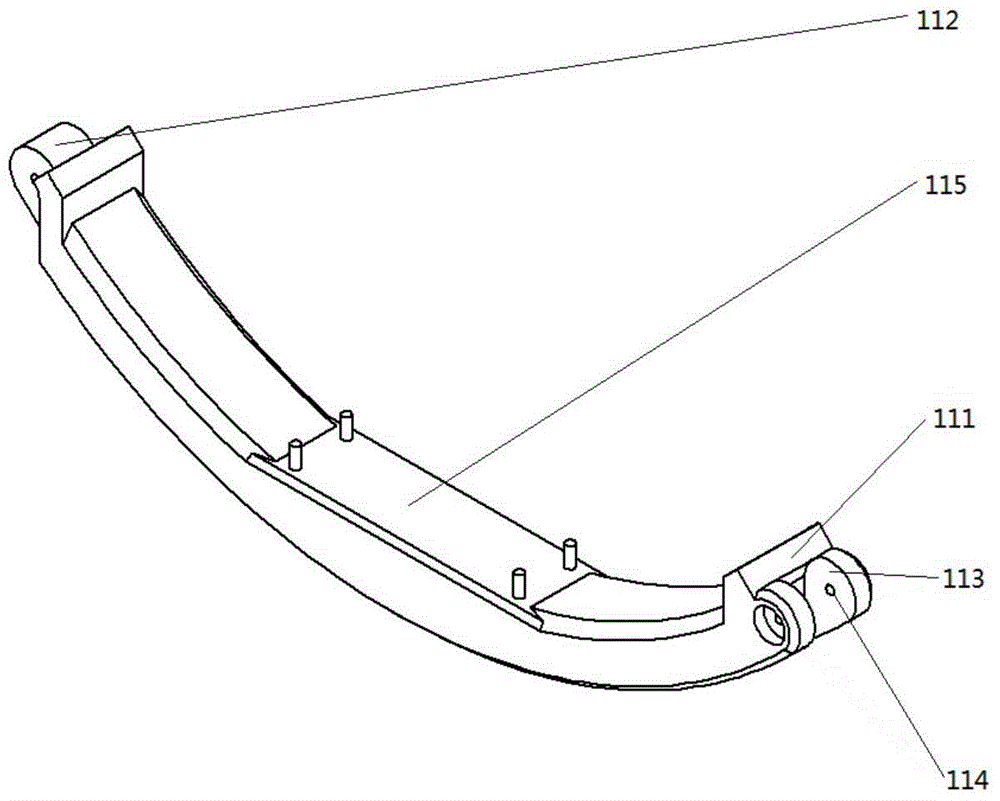

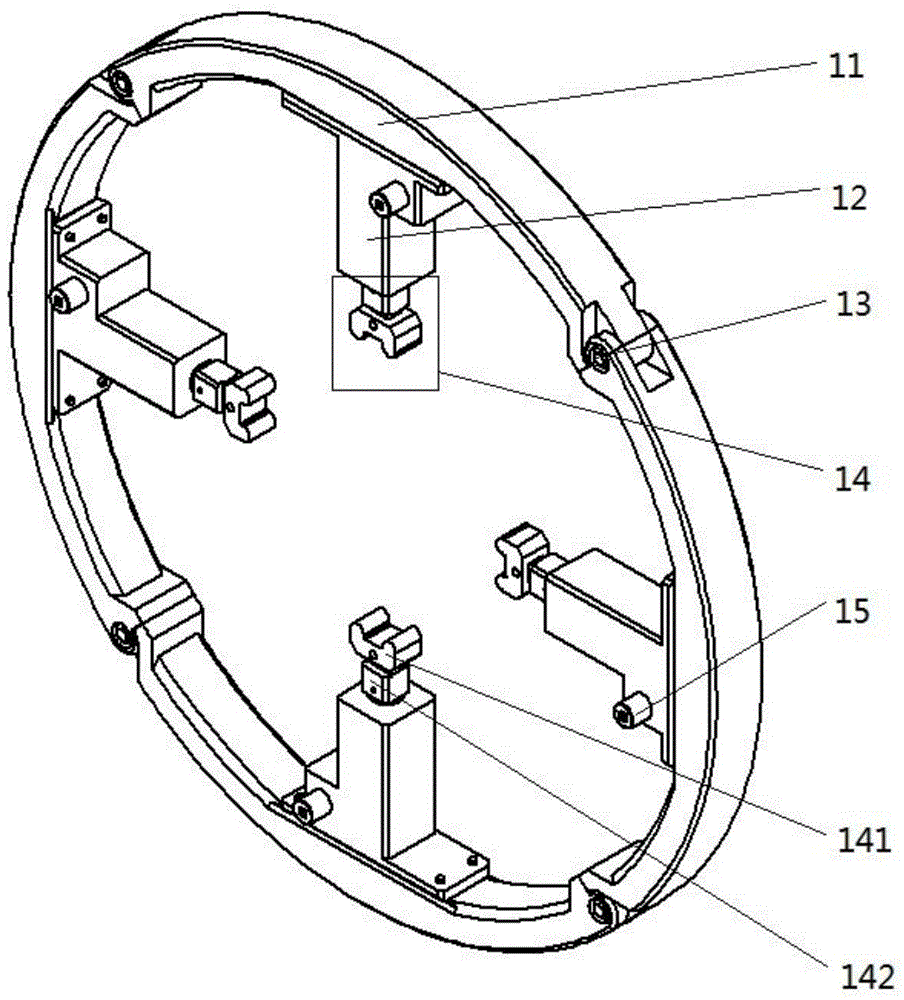

[0034] refer to figure 1 , The present invention includes an annular adjustable clamp 1, a clamp adjustment device 2, a clamp adjustment device bracket 3, a clamp support 4, a carriage slide 5, a guide rail 6 and a base 7. The annular adjustable clamp 1 includes an outer ring frame 11, a telescopic device 12, a quick release pin 13, a claw 14 and a transmission sleeve 15, and the four outer ring frames 11 are movably connected from the end to the end by the quick release pin 13 to form an annular adjustable clamp body. In order to rotate the annular adjustable clamp 1 around the axis on the clamp support 4 . A telescopic device 12 is installed radially in the middle of the inner side of the outer ring frame 11, and a transmission sleeve 15 is installed on the side of the lower end of the telescopic device 12. The worm 126 is connected, and the transmission sleeve 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com