Mixed feeding device of metallurgical powder

A technology of feeding device and metallurgical powder, applied in the field of powder metallurgy production tools, can solve problems such as affecting the consistency of output products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

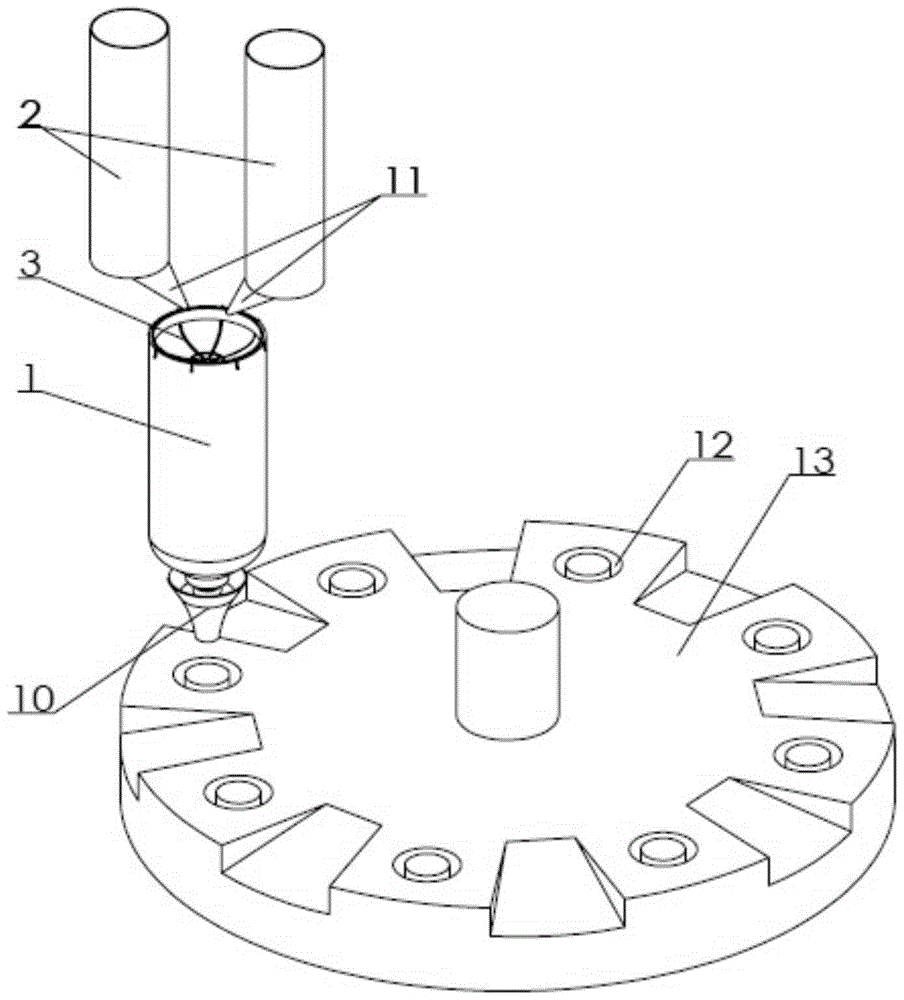

[0014] Examples of the present invention figure 1 , 2 As shown, the metallurgical powder mixing and feeding device is provided with a receiving barrel 1 and an injection barrel 2. The receiving barrel is a rotating body, and the upper opening is provided with circumferentially distributed ribs 3 embedded in it for impacting the incoming powder. , so that the route can be changed, and multi-layer staggered distribution can be set during implementation, so that the powder fall tends to be more natural and dispersed, and the mixing is more complete. The bottom axis of the receiving barrel is provided with a discharge port 4, and the discharge port is provided with a spindle-shaped Flow regulating body 5, the flow regulating body is connected with a bracket 7 in the material receiving barrel through the screw rod 6 extending upwards, the flow rate can be adjusted by adjusting the distance between the flow regulating body and the discharge port, and the outflowing powder is dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com