Self-sinking filter residue device of slag extractor

A self-sinking, slag removal technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve problems such as increased cost, slag blockage and ineffectiveness, and inability to separate slag and iron, and achieves stability and reliability. The effect of the filter residue remains stable and the effect of ensuring the effect of the filter residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

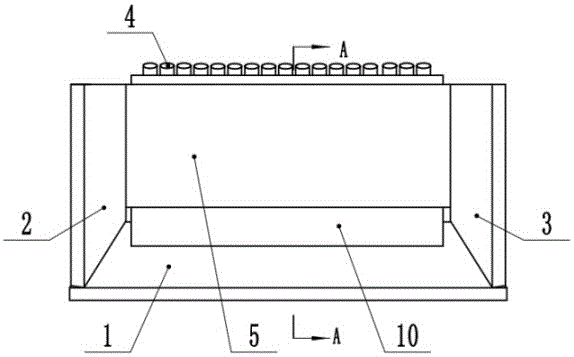

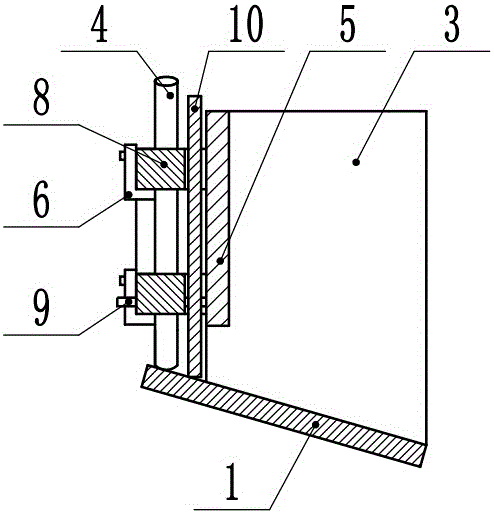

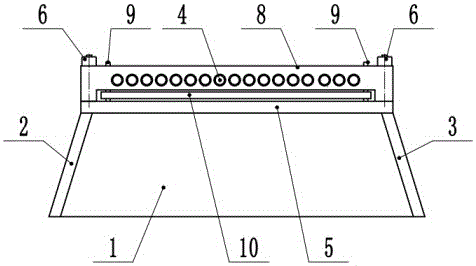

[0034] Such as Figures 1 to 3 , each upright bar 4 is individually movable and installed in the positioning groove of the grid bracket 8 to ensure that the upright bar 4 can sink freely when gravity or external force impacts, so as to ensure that the bottom end of each upright bar 4 is always in contact with the bottom plate 1 ; The present embodiment also includes a vertical plate 5 located inside the grid, the front and rear ends of the vertical plate 5 are connected to the front end plate 2 and the rear end plate 3 respectively, and the lower edge of the vertical plate 5 is connected to the bottom plate 1 There is a gap between them; the grid support 8 is fixed on the vertical plate 5 through the card slot 6. The bottom plate 1 , the front end plate 2 , the rear end plate 3 and the vertical plate 5 form a slag filter device in the form of a slag rake with openings on the inner surface and the upper end surface.

[0035] On the inner side of the grid, there is also a slag ...

specific Embodiment 2

[0041] Such as Figure 4-6 , the vertical bar 4 is fixed on the grid bracket 8, and the grid is installed in the vertical guide groove to ensure that the grid can sink freely when the gravity or external force impacts, so as to always ensure that the bottom end of the grid is in contact with the bottom plate 1; The vertical guide groove is arranged on the front end plate 2 and the rear end plate 3 . The bottom plate 1, the front end plate 2, the rear end plate 3 and the grill form a slag filter device in the form of a slag rake with openings on the inner surface and the upper end surface.

[0042] In order to ensure the strength of the device at high temperature, a number of reinforcing plates 7 are also arranged between the front end plate 2 and the rear end plate 3, the reinforcing plates 7 are located above the bottom plate 1 and there is a gap between the lower edge of the reinforcing plate 7 and the bottom plate 1. The front and rear ends of the reinforcing plate 7 are c...

specific Embodiment 3

[0049] The specific embodiment 2 may also include a vertical plate located inside the grid, the front and rear ends of the vertical plate are respectively connected to the front end plate and the rear end plate, and there is a gap between the lower edge of the vertical plate and the bottom plate. The bottom plate, the front end plate, the rear end plate and the vertical plate enclose a slag filter device in the form of a slag rake with openings on the inner surface and the upper end surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com