Converter station with diode rectifier

A diode rectifier and converter station technology, applied in the field of converter stations, can solve the problems of high manufacturing cost, space occupation, and weight of converter stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

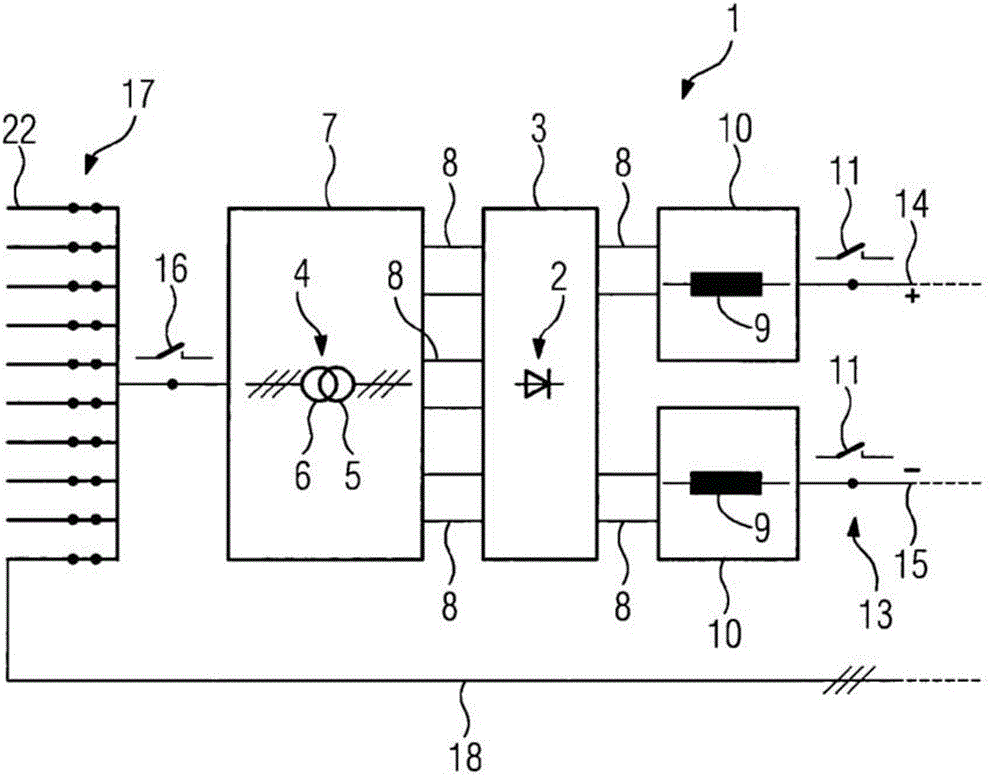

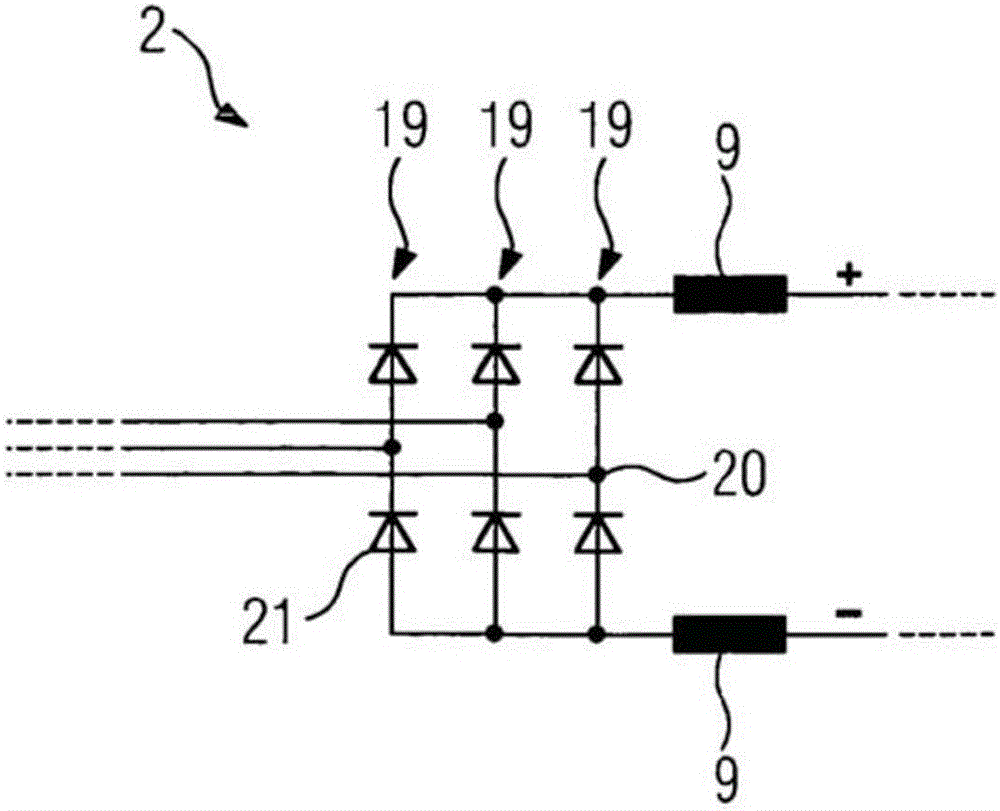

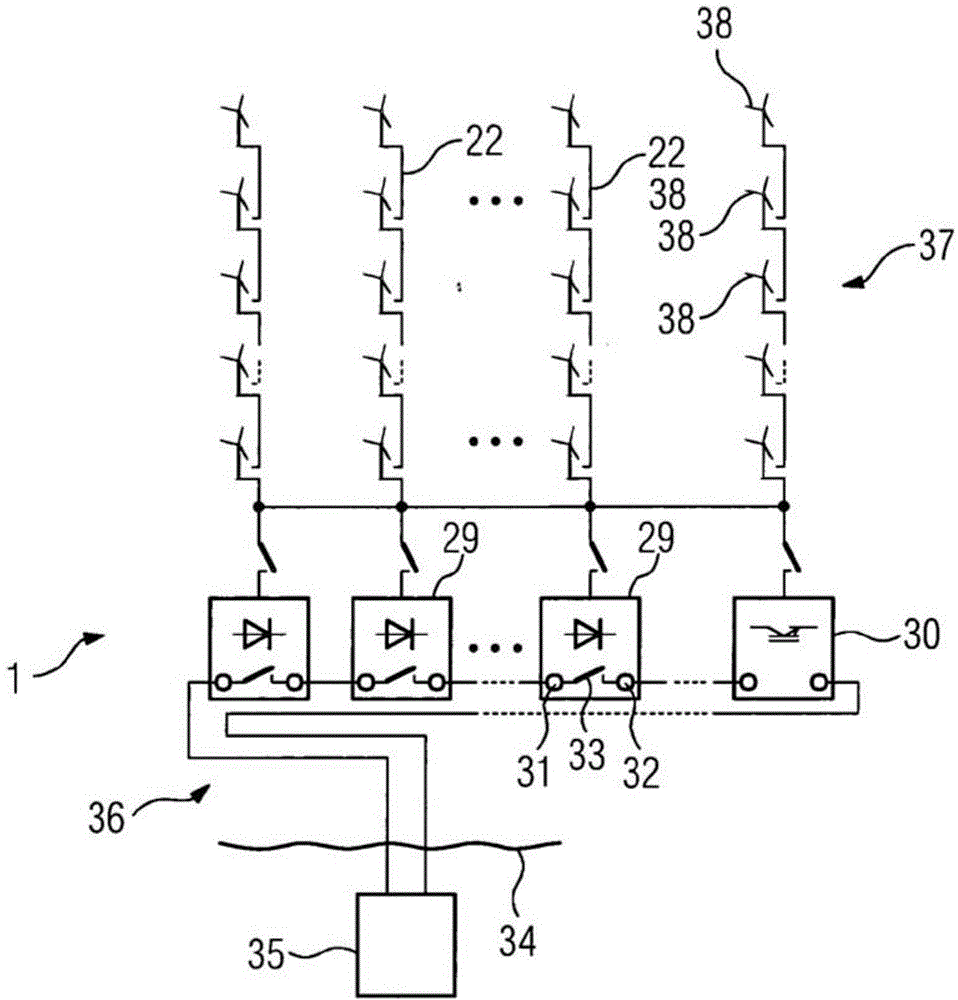

[0034] figure 1 An embodiment of a converter station 1 according to the invention is shown having a diode rectifier 2 arranged in an encapsulation housing 3 filled with insulating material. insulating material in figure 1 The example shown is insulating oil. Furthermore, the converter station 1 comprises a transformer 4 having a primary winding 5 and a secondary winding 6 which are inductively coupled to one another. The transformer 4 is arranged in an encapsulation case 7 filled with the same insulating oil. A hollow-cylindrical supply line 8 , likewise filled with insulating oil, is used for routing the phase conductors connected on the AC voltage side between the transformer 4 and the converter 2 . The encapsulation housings 3 , 7 are at ground potential.

[0035] The converter station 1 also has two smoothing inductors 9 , which are each connected to the two DC voltage connections of the diode rectifier 2 . Each smoothing inductor 9 is arranged in a separate encapsula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com