High performance electronic system with first and second subsystem

A technology of power electronics and subsystems, which is applied in the direction of circuits, electrical components, and electric solid-state devices, and can solve problems such as inability to construct units, inability to scale, and inability to match

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

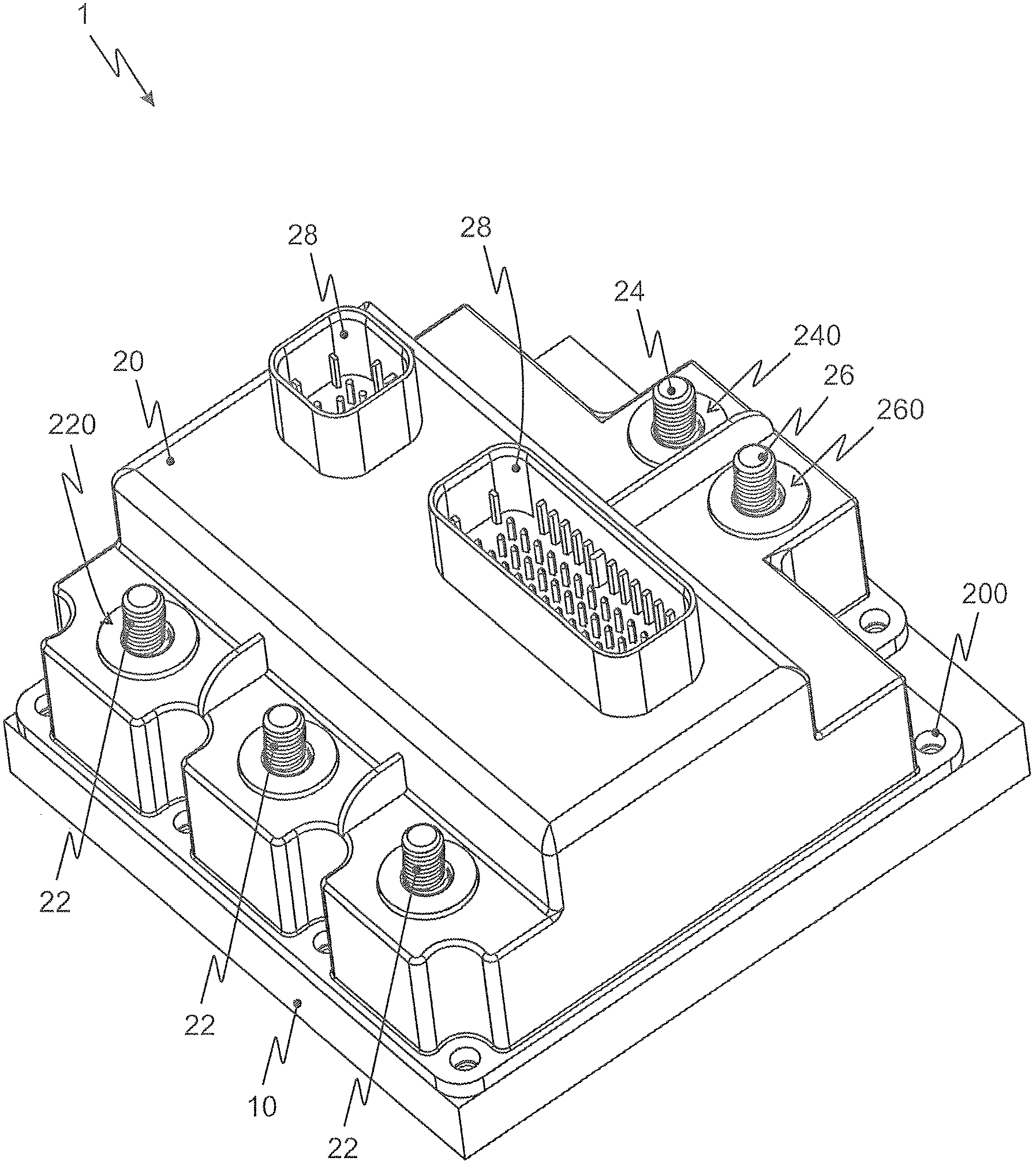

[0021] figure 1 The first power electronics system 1 according to the invention in the design of a three-phase inverter is shown in a three-dimensional illustration. A cooling device 10 , for example configured as a water cooling device, is shown schematically. The internal components of the system are covered by a housing 20 facing the cooling device 10 . The housing 10 itself is penetrated by the external coupling elements 22 , 24 , 26 at the respective recesses 220 , 240 , 260 .

[0022] Two outer DC voltage load connection elements 24 , 26 designed as screw connections are arranged on a first end side of housing 10 . On the second, opposite end side of the housing 10 , an external AC voltage load connection element 22 is shown in substantially the same technical manner.

[0023] External auxiliary coupling elements 28 are provided in two groups on the upper end side, in particular for coupling control signals and sensor signals.

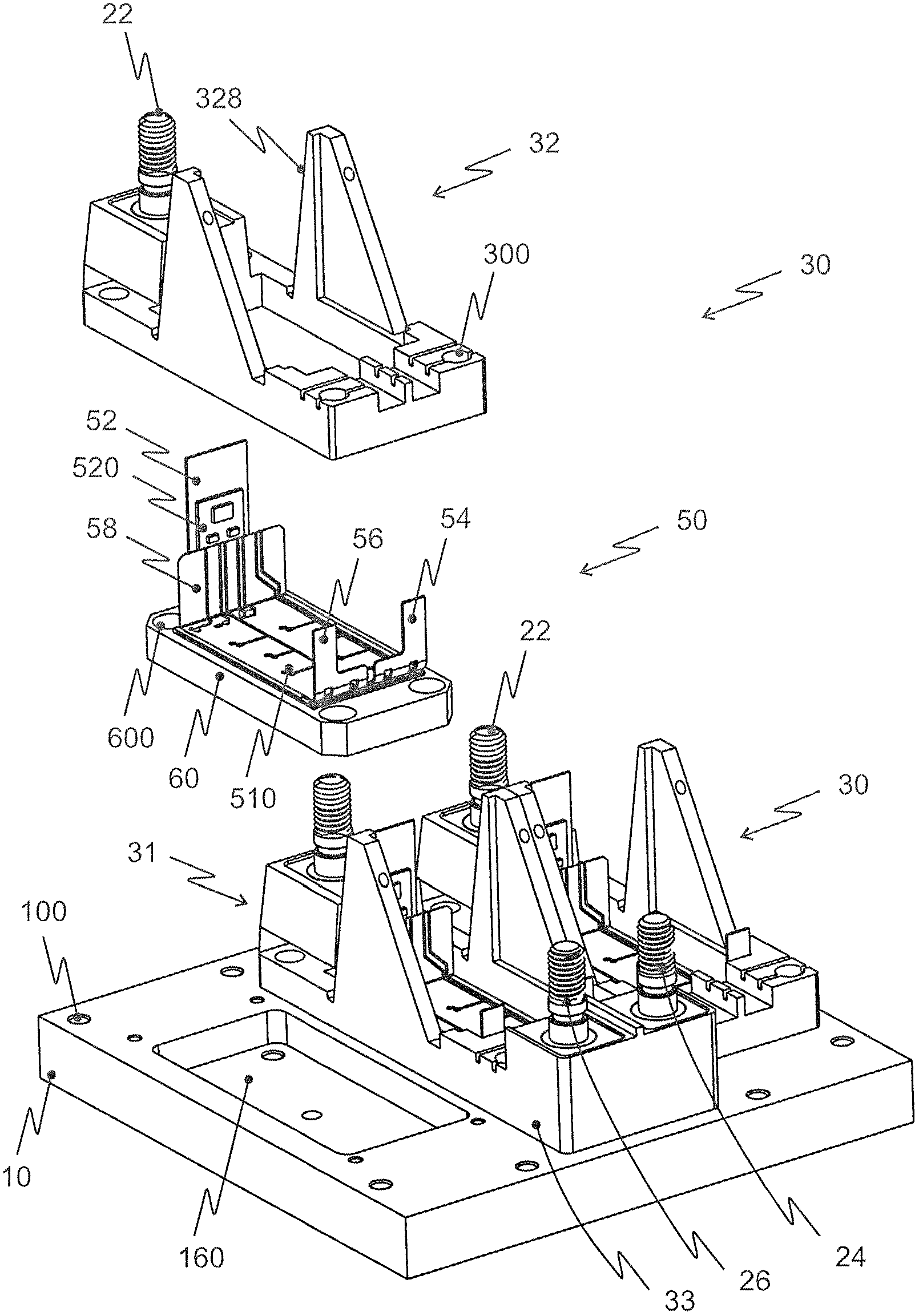

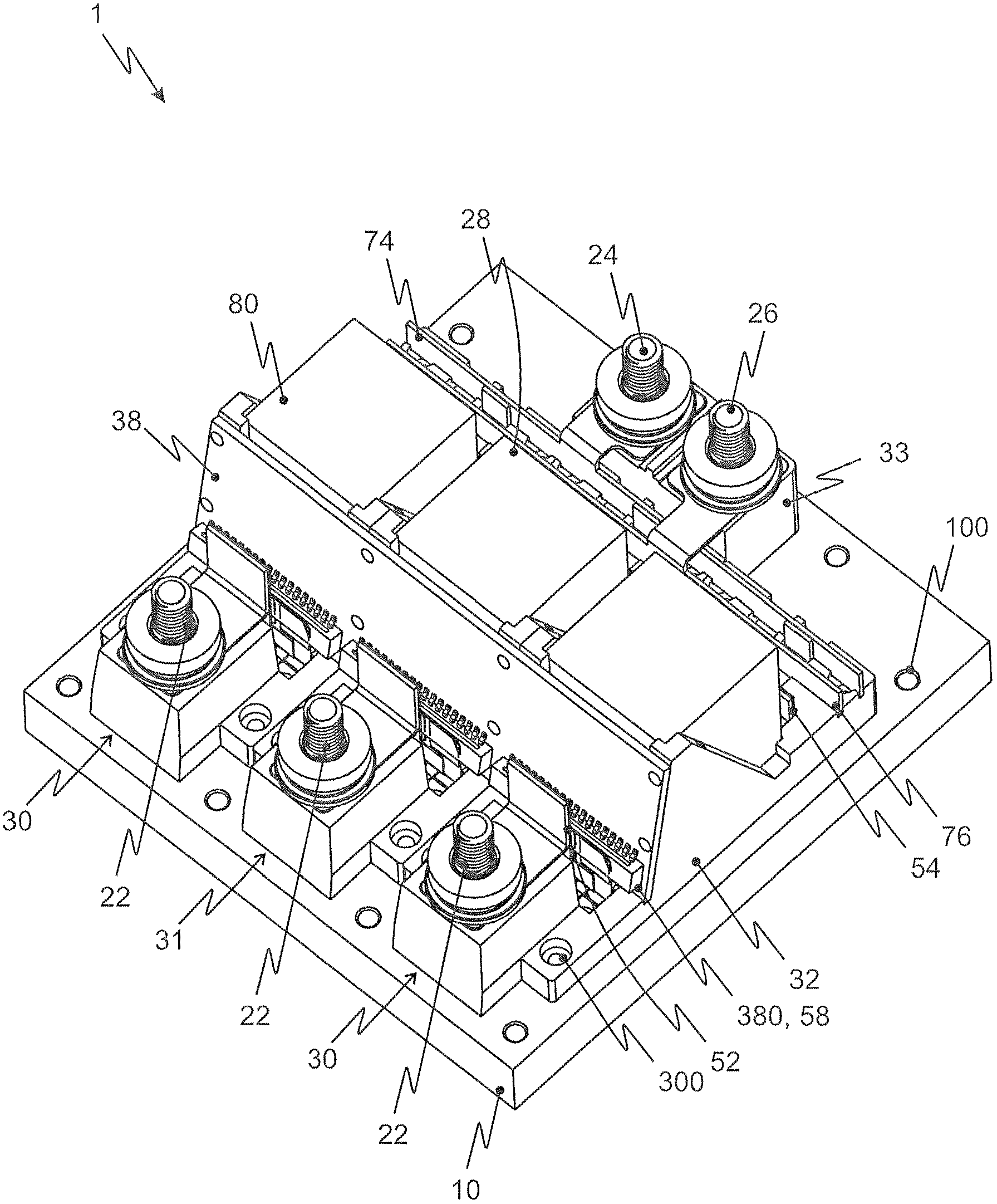

[0024] figure 2 and 3 A partially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com