Ground terminal of ground wire

A grounding terminal and grounding wire technology, applied in the direction of electrical connection seat, clamping/spring connection, etc., can solve the problems of easy falling, safety accident, plane tilt, etc., and achieve the effect of increasing reliability and preventing safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

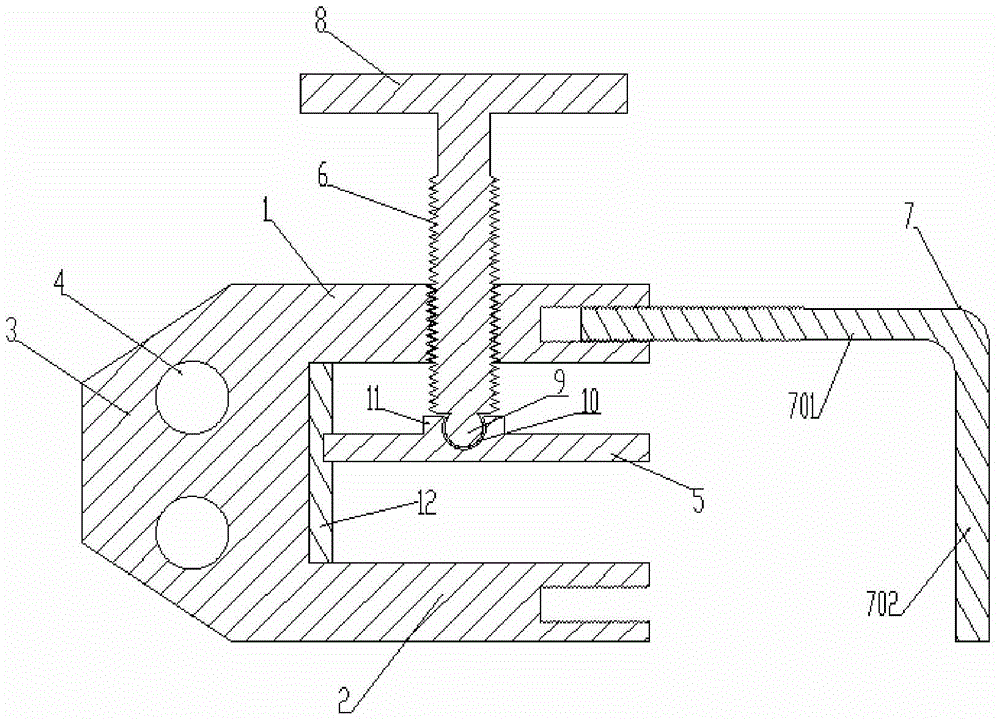

[0031] figure 1 It is a schematic structural diagram of the ground terminal of the ground wire provided in Embodiment 1 of the present invention, Figure 4 It is a schematic diagram of the structure between the intermediate pressure plate and the sliding rod, refer to figure 1 with Figure 4 , The grounding terminal includes a wire clamp body, the wire clamp body includes an upper pressing plate 1, a lower pressing plate 2, and a connecting plate 3 between the upper pressing plate 1 and the lower pressing plate 2. The upper pressing plate 1 and the lower pressing plate 2 are arranged in parallel, so The upper pressing plate 1, the lower pressing plate 2 and the connecting plate 3 are formed as an integral structure, so that the integrity of the grounding terminal is good, and loosening is avoided. The cross-section of the wire clip body is U-shaped, the connecting plate 3 is provided with two wire holes 4, the inside of the wire clip body is provided with a movable middle press...

Embodiment 2

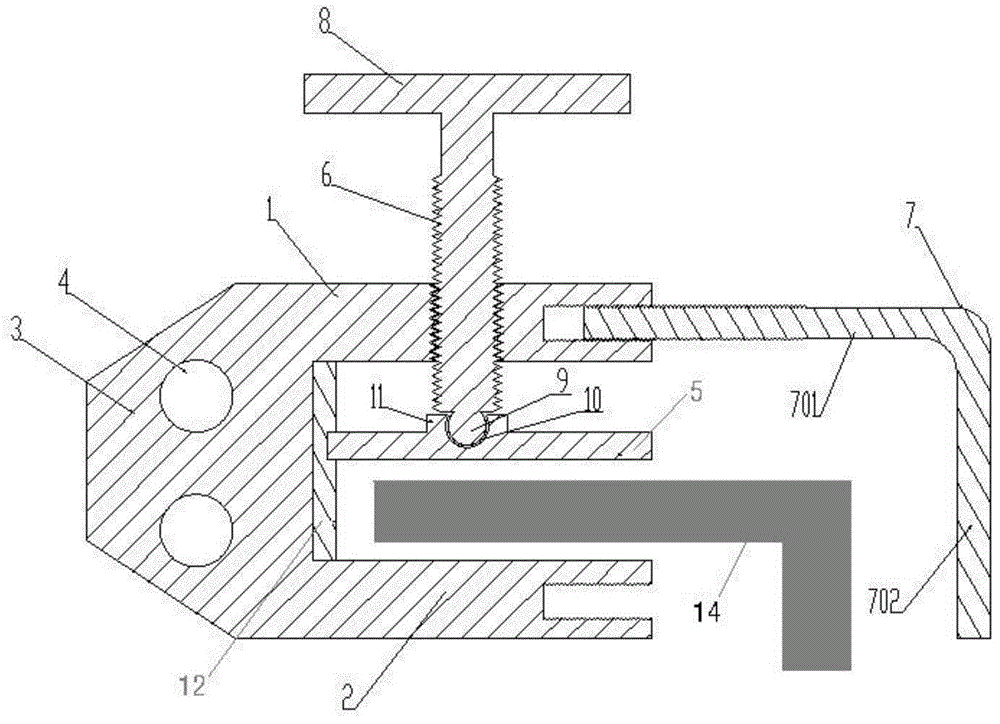

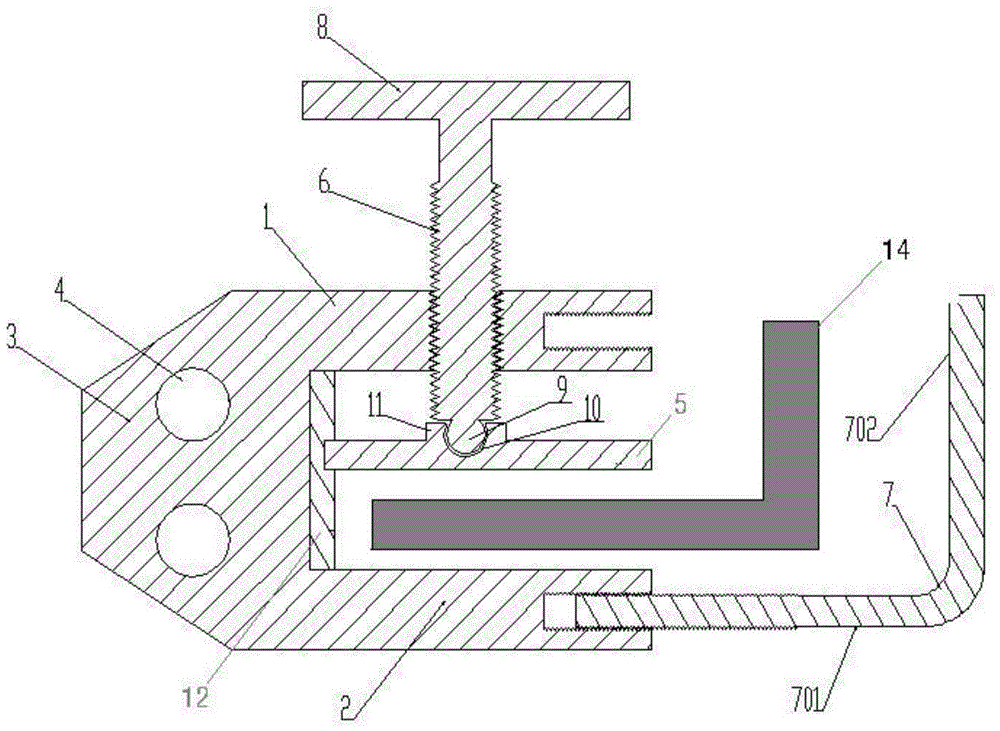

[0036] image 3 It is a schematic diagram of the structure of the ground terminal of the ground wire provided in Embodiment 2 of the present invention, Figure 4 It is a schematic diagram of the structure between the intermediate pressure plate and the sliding rod, refer to image 3 with Figure 4 The grounding terminal includes a wire clamp body, which includes an upper pressure plate 1, a lower pressure plate 2, and a connecting plate 3 between the upper pressure plate 1 and the lower pressure plate 2. The upper pressure plate 1 and the lower pressure plate 2 are arranged in parallel, so The upper pressing plate 1, the lower pressing plate 2 and the connecting plate 3 are an integrated structure, the cross section of the wire clip body is U-shaped, the connecting plate 3 is provided with more than one wire hole 4, the wire clip body There is a movable middle pressing plate 5 inside the middle pressing plate 5, the upper pressing plate 1 and the lower pressing plate 2 are para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com