Control method of dry cleaning machine and dry cleaning machine

A control method and technology for a dry cleaning machine, applied in the field of washing machines, can solve problems such as inability to judge the concentration of dry cleaning solvent vapor, waste of dry cleaning solvent, environmental pollution, etc., and achieve the effects of avoiding dry cleaning solvent leakage, improving safety, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In this embodiment, the set value Pb is stored in the dry cleaning machine, which is compared with the detection value P to determine whether the drying of the dry cleaning machine is over; and the safety value Pa is compared with the detection value P to determine The value of whether the door of the dry cleaner can be opened. Said set value Pb>safety value Pa.

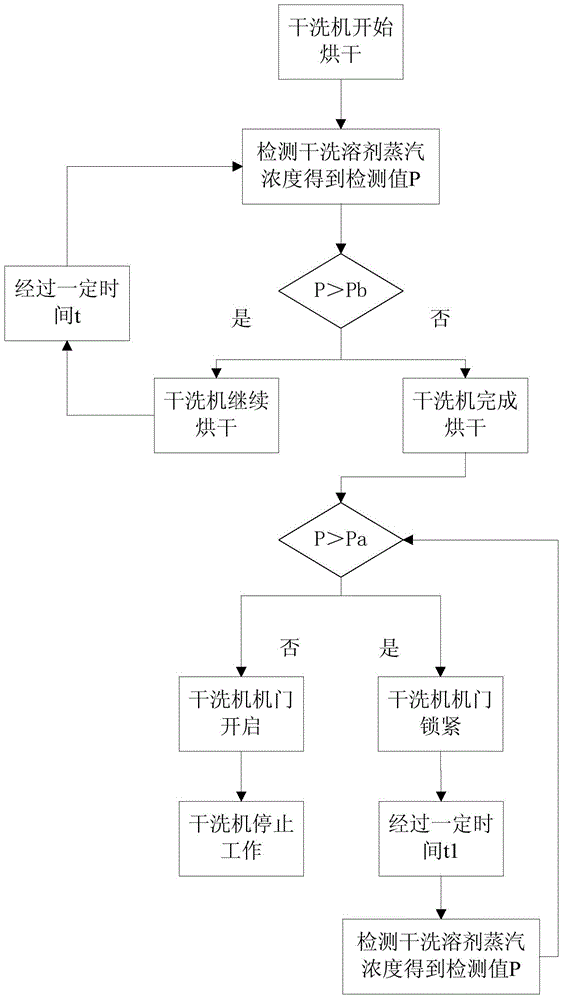

[0055] like figure 1 As shown, the specific working process of the dry cleaning machine is as follows:

[0056] 1) The dry cleaning machine starts to work. After performing the washing and drying procedures in sequence, it starts to enter the drying procedure, and uses the concentration sensor to detect the concentration value of the dry cleaning solvent vapor in the circulating air path composed of the drying air path and the outer cylinder, and obtains the detection value. value P;

[0057] 2) Compare the detection value P with the preset value Pb in the dry cleaning machine: when P>Pb, the dry cleaning m...

Embodiment 2

[0064] The difference between this embodiment and the first embodiment is that: the set value Pb=safety value Pa.

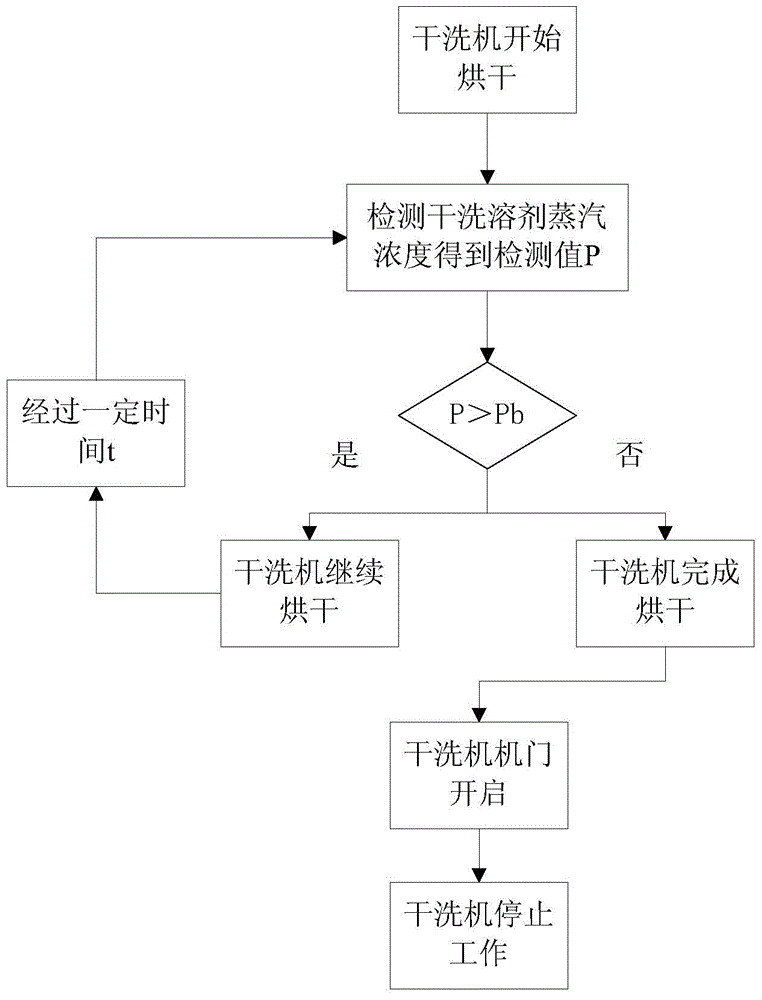

[0065] like figure 2 As shown, the specific working process of the dry cleaning machine is as follows:

[0066] 1) The dry cleaning machine starts to work. After performing the washing and drying procedures in sequence, it starts to enter the drying procedure, and uses the concentration sensor to detect the concentration value of the dry cleaning solvent vapor in the circulating air path composed of the drying air path and the outer cylinder, and obtains the detection value. value P;

[0067] 2) Compare the detection value P with the preset value Pb in the dry cleaning machine: when P>Pb, the dry cleaning machine continues to dry, and perform step 3); when P≤Pb, the dry cleaning machine stops drying, Execute step 4);

[0068] 3) After a certain period of time t, the concentration sensor detects the concentration value of the dry cleaning solvent vapor again t...

Embodiment 3

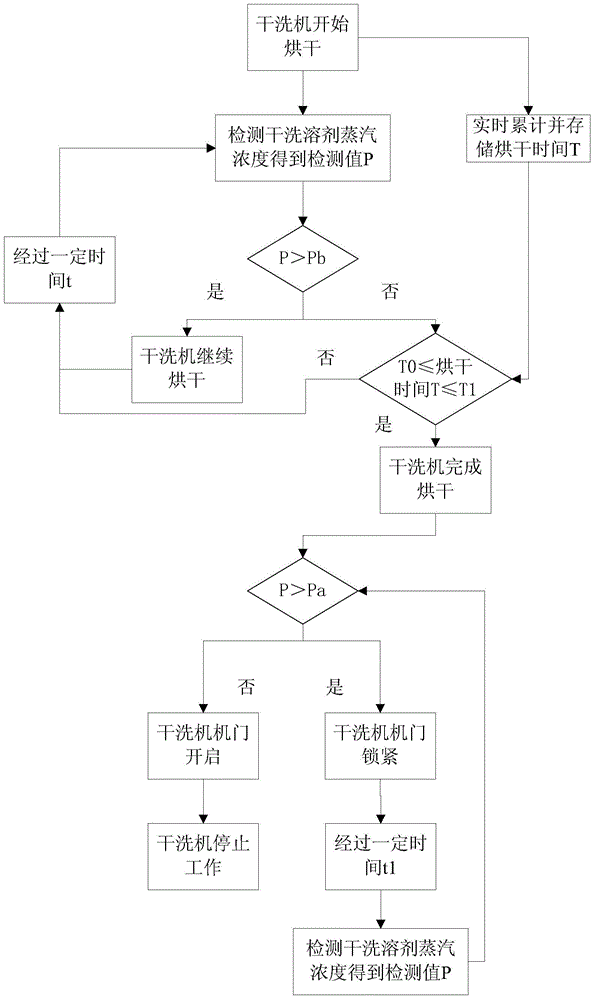

[0071] The difference between this embodiment and Embodiment 1 is that the dry cleaning machine is provided with a pre-judgment time T0-T1. When the dry cleaning machine satisfies the following two conditions at the same time: the drying time T is between the predicted time T0 ~ T1, and the detection value of the dry cleaning solvent vapor concentration P ≤ the set value Pb, the dry cleaning machine will finish drying.

[0072] like image 3 As shown, the specific working process of the dry cleaning machine is as follows:

[0073] 1) The dry cleaning machine starts to work. After performing the washing and drying procedures in sequence, it starts to enter the drying procedure, time the drying time T, and use the concentration sensor to detect the concentration in the circulating air path composed of the drying air path and the outer cylinder The concentration value of dry-cleaning solvent vapor obtains the detection value P;

[0074] 2) Compare the detection value P with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com