A positioning reference mechanism

A positioning datum and positioning block technology, which is applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of inaccurate positioning and achieve the effect of fast and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

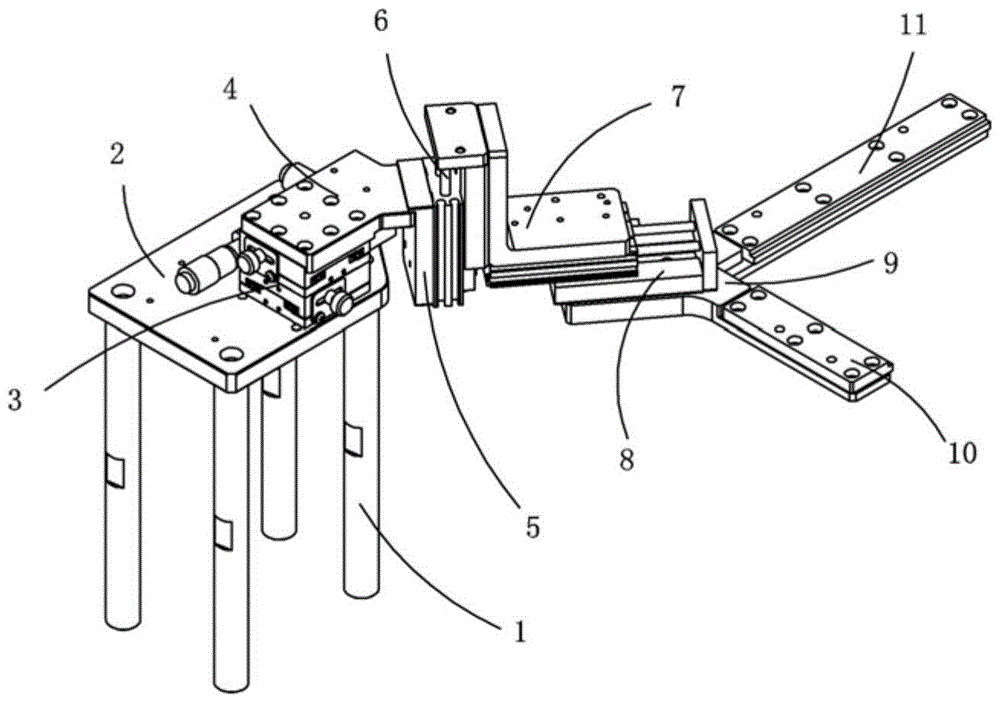

[0017] Examples, see attached figure 1 with 2 , a positioning reference mechanism, which includes a support column 1, a support plate 2 is installed on the support column, there are four sets of support columns, and each set of support columns is respectively installed at the four corners of the bottom of the support plate.

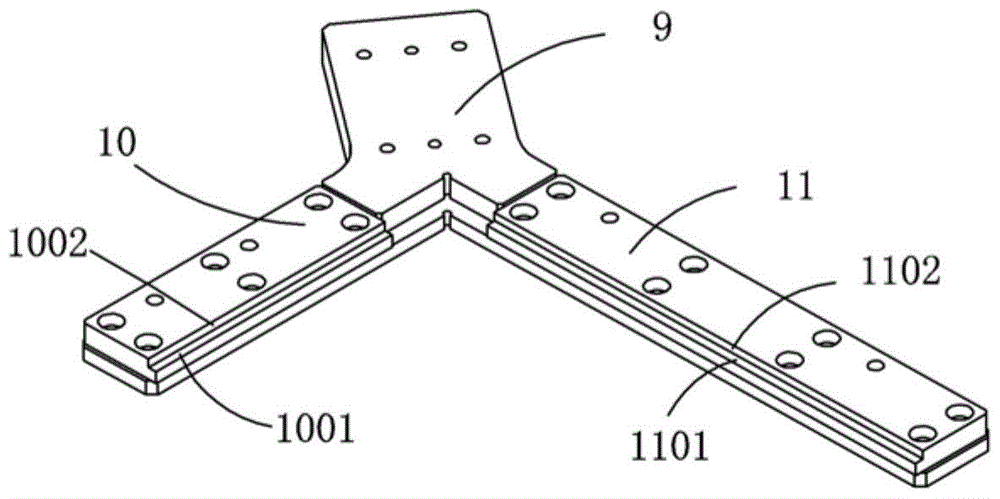

[0018] A precision sliding table 3 is installed on the support plate, and the precision sliding table can finely adjust the position of the positioning reference block. A slide table connection plate 4 is installed on the precision slide table, and a lift cylinder connection plate 5 is vertically installed on the front side of the slide table connection plate; a lift cylinder 6 is installed on the lift cylinder connection plate; the slide table of the lift cylinder Telescopic cylinder connecting plate 7 is installed on it, and telescopic cylinder 8 is installed on the bottom of telescopic cylinder connecting plate, and positioning reference block 9 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com