A centering device before barrel grinding

A centering device and crystal ingot technology, which is applied in positioning devices, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as inability to bond crystal rods and centering blocks, so as to improve product production efficiency, Avoid bad alignment problems, high precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

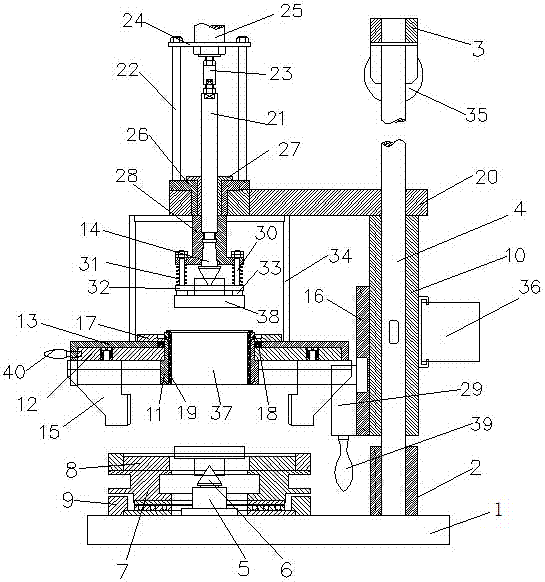

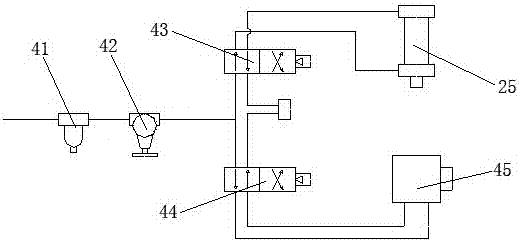

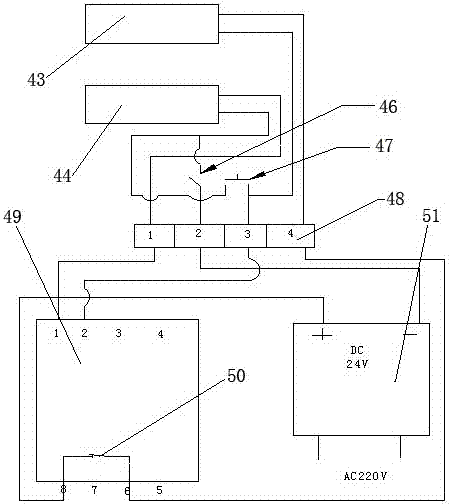

[0022] Such as figure 1 As shown, a centering device before crystal ingot rolling includes a lower positioning mechanism, an intermediate chuck mechanism for clamping the crystal ingot, an upper positioning mechanism and a column 4, wherein the lower end of the column 4 is fixed on one side of the lower positioning mechanism, and the upper The positioning mechanism is fixedly connected to the upper part of the column 4 through the suction cup base 20. The sliding sleeve in the middle of the column 4 is provided with a sliding sleeve 10 and a sliding sleeve brake assembly 36 that controls the sliding of the sliding sleeve 10 on the column 4. The middle chuck mechanism is fixed by the chuck. Plate 16 is fixed with sliding sleeve 10;

[0023] The lower positioning mechanism includes a base plate 1, a lower cone sleeve 5 disposed on the base plate 1, and a lower centering cone 6 disposed on the lower cone sleeve 5;

[0024] Described intermediate chuck mechanism comprises chuck 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com