Fourth-axis and fifth-axis clamp

A shaft clamp, the fourth technology, applied in the field of fixtures, can solve the problems of low product processing accuracy, waste of processing time, and large cumulative tolerances, and achieve high processing accuracy, avoid collision damage, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

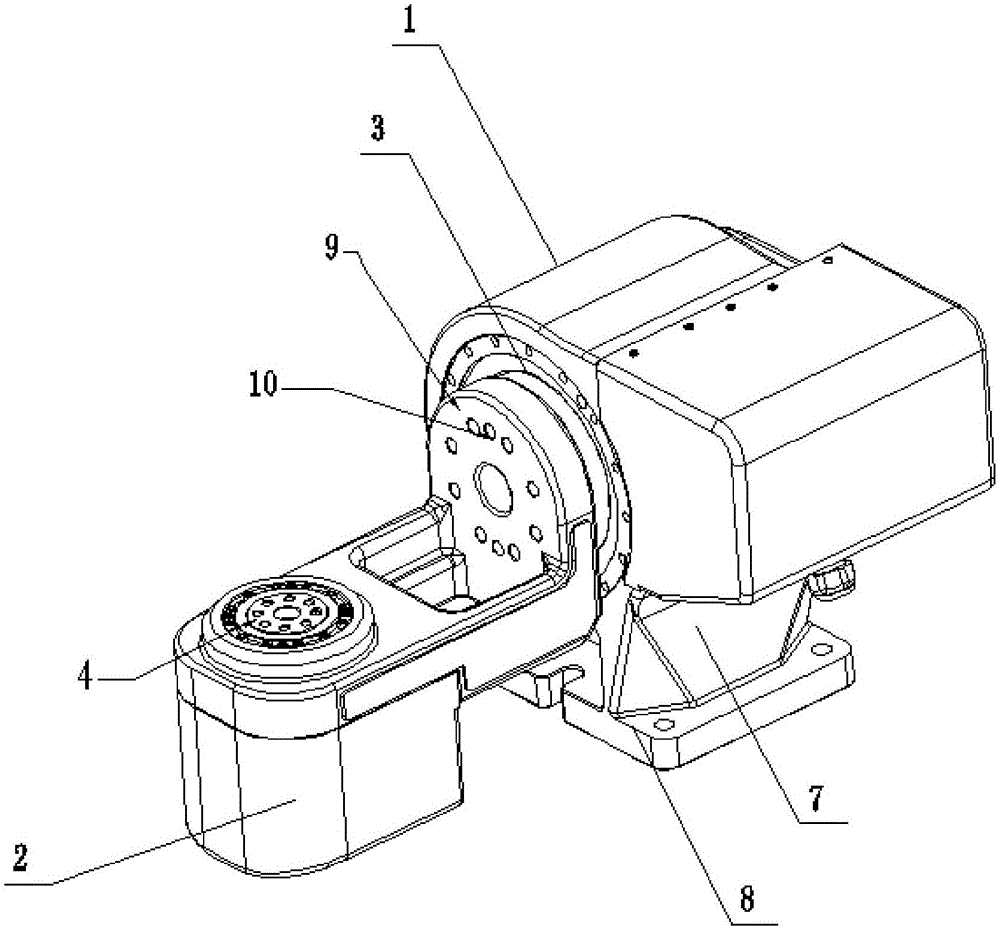

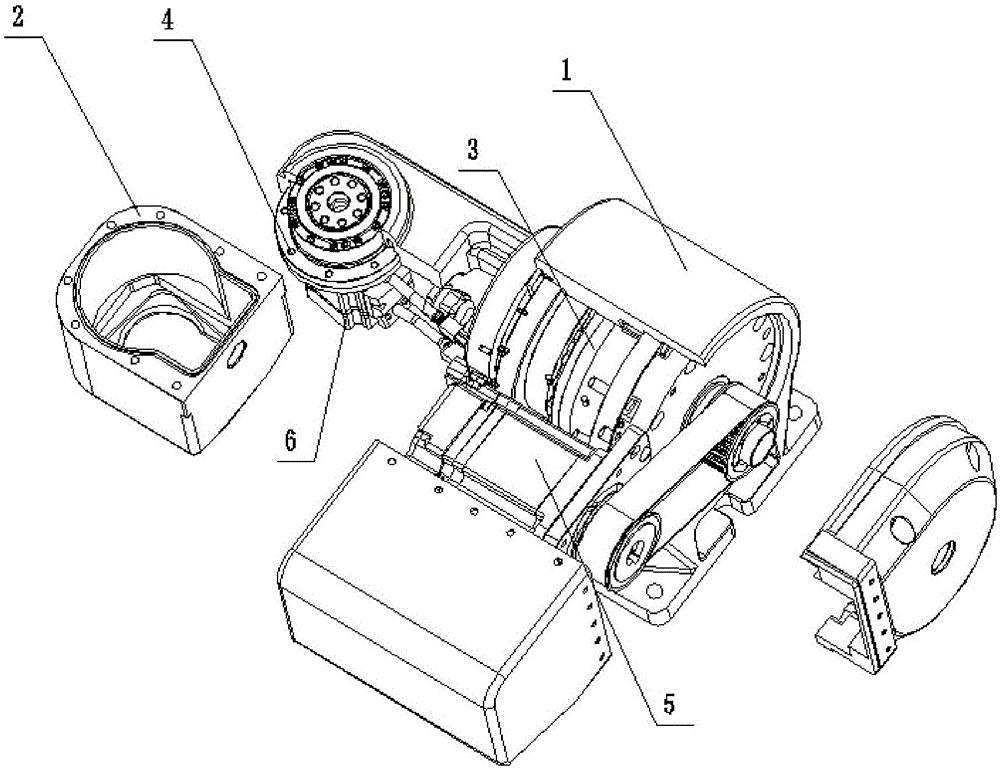

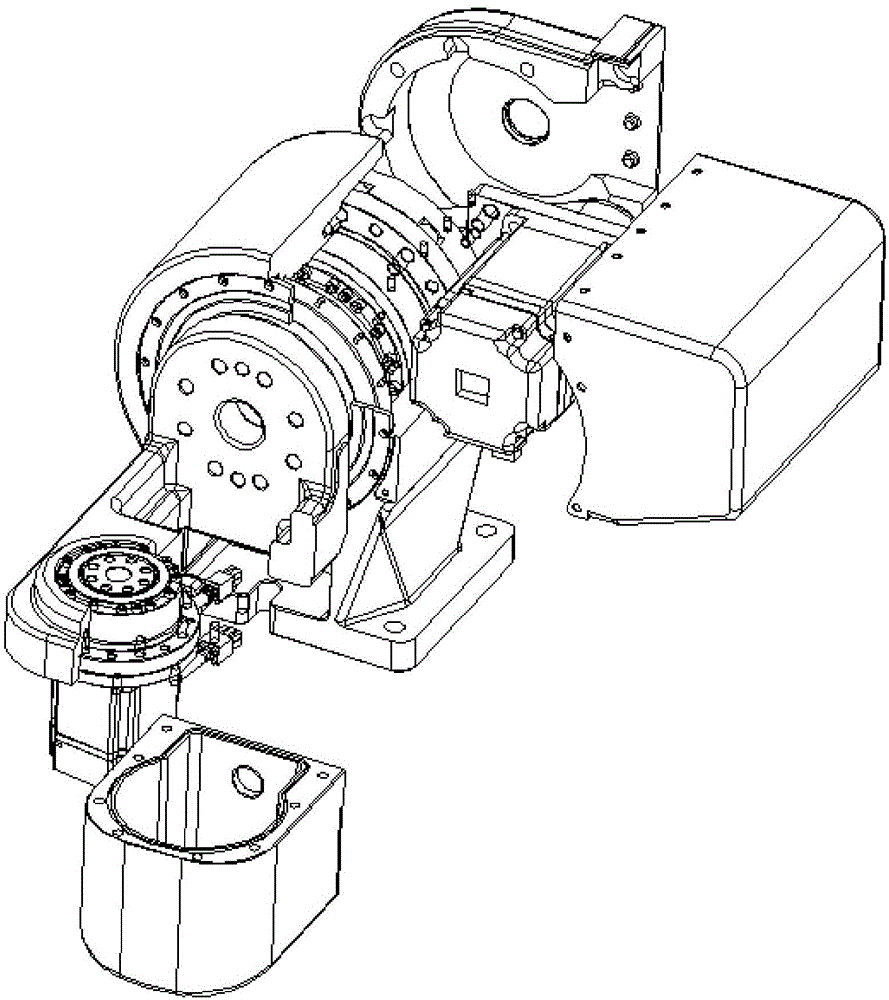

[0016] Embodiment: A fourth and fifth axis fixture, including first and second bodies 1 and 2, first and second harmonic reducers 3 and 4, first and second motors 5 and 6, fixtures and controllers, the first The steel wheel of a harmonic reducer is fixedly installed in the first body, the power output end of the first servo motor is fixedly connected with the waveform generator of the first harmonic reducer, and the second body is connected with the flexible motor of the first harmonic reducer. The wheels are fixedly connected, the steel wheel of the second harmonic reducer is fixedly installed in the second body, the power output end of the second servo motor is fixedly connected with the waveform generator of the second harmonic reducer, and the first and second harmonic The axial directions of the wave reducer 3 and 4 are perpendicular to each other, and the tooling fixture is fixedly installed on the flexible wheel of the second harmonic reducer. The tooling fixture is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com