A brushless motor support structure with a power control box

A power control box, brushless motor technology, applied in the direction of the casing/cover/support, electromechanical devices, electrical components, etc., can solve the problem of not effectively solving the rotation and movement of the shock absorbing ring, and increasing the difficulty and cost of maintenance and repair , the increase in the overall size of the equipment, etc., to achieve the effect of compact structure, avoiding rotation and movement, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

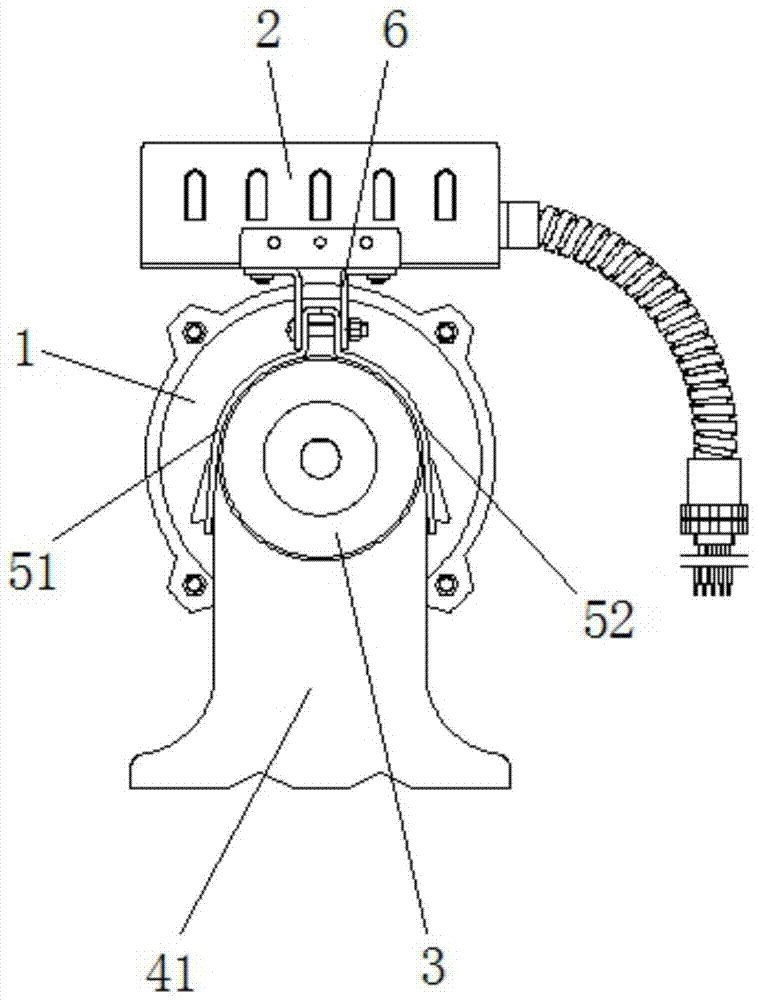

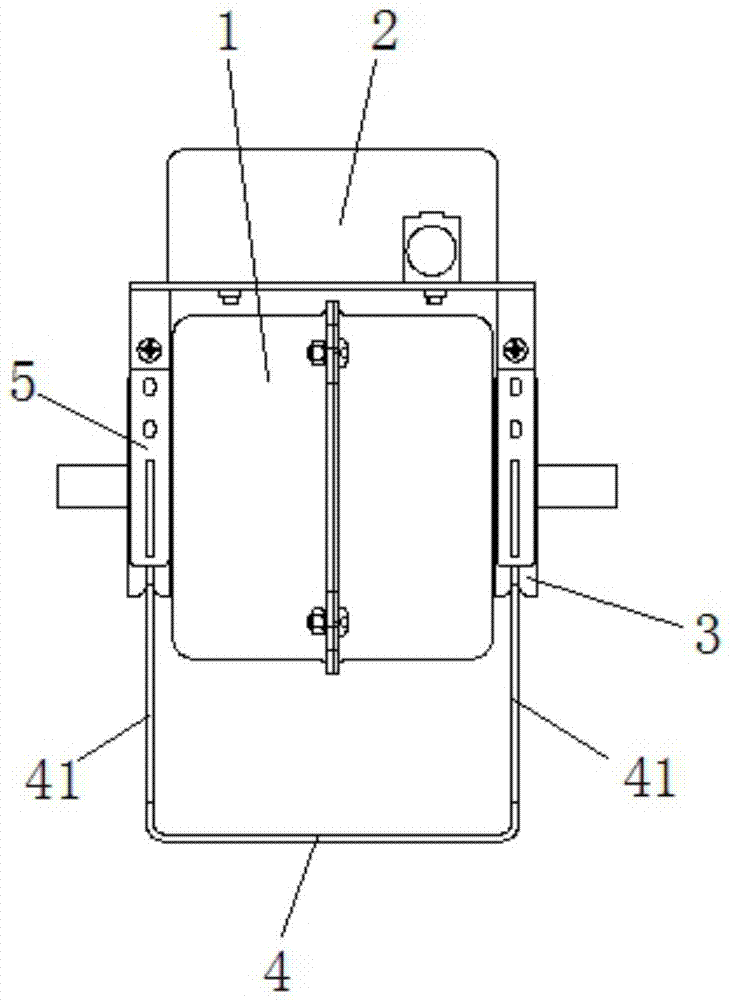

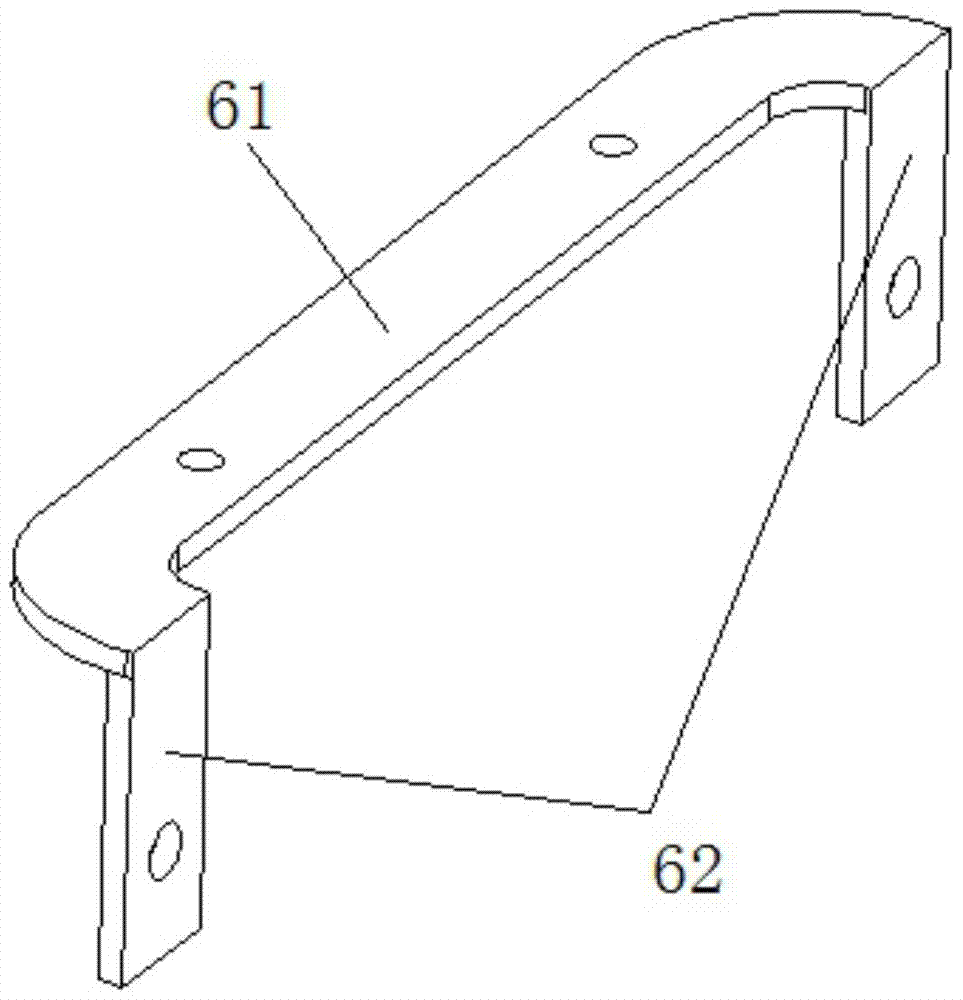

[0016] See Figure 1 to Figure 3 , the present invention includes a motor 1, a power control box 2, a shock absorbing ring 3, a base bracket 4 and a clamp assembly 5; the two ends of the base bracket 4 protrude upward from support plates 41, and each support plate 41 is provided with a concave slot and block; the clip assembly 5 includes a first clip 51, a second clip 52 and a connecting bolt; Buckle slots, the upper ends of the first buckle clip 51 and the second buckle clip 52 are provided with connecting holes; the two ends of the shell of the motor 1 are provided with shock absorbing rings 3, and the shock absorbing rings 3 are clamped on the two ends of the base bracket 4. In the groove of the support plate 41; the lower ends of the first buckle clip 51 and the second buckle clip 52 are fastened on the support plate 41 through the buckle groove and the block, and the first buckle clip 51 and the second buckle clip 52 are clamped After the damping ring 3 is held, the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com