The structure of the pressure balance valve with built-in louvers in double-layer insulating glass

A technology of double-layer insulating glass and blinds, which is applied in the direction of windows/doors, building components, building structures, etc., can solve the problems of mildew, trouble in manufacturing and assembling, breeding of bacteria, etc. of double-layer insulating glass, so as to avoid human touch. damage, beneficial to production and installation, good concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

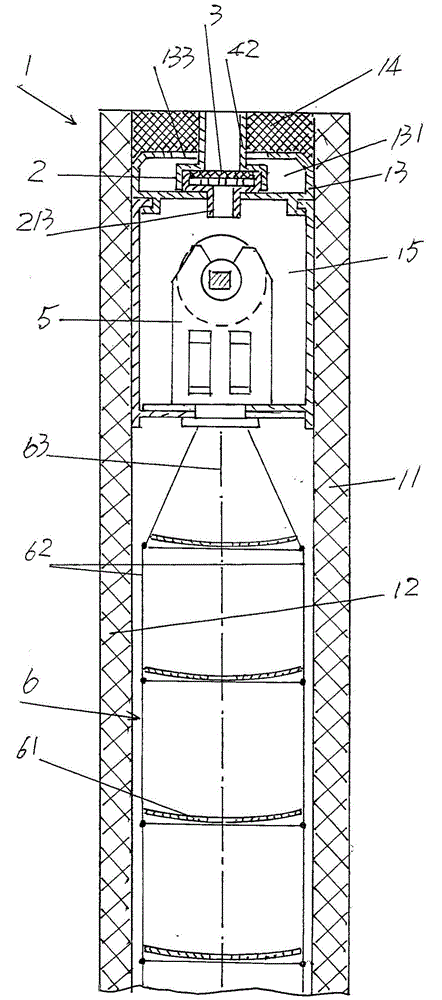

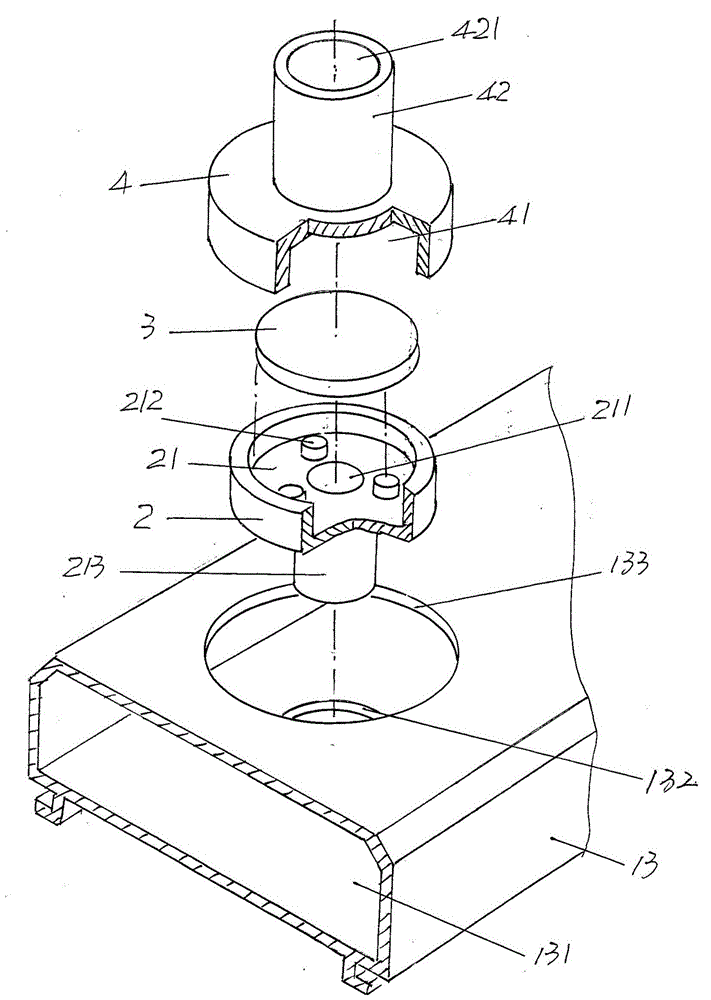

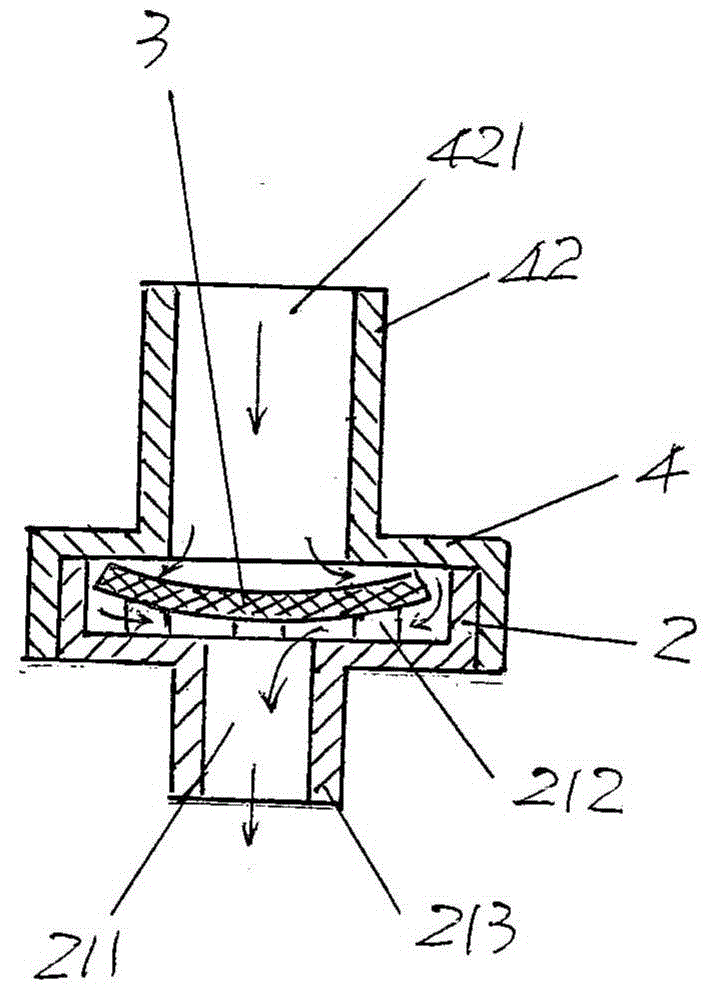

[0023] See figure 1 , gives the window 1 belonging to the structural system of the double-layer hollow glass inner shutter, the window 1 includes the inner glass 11, the outer glass 12, the window frame tube 13 and the sealing strip 14, the inner and outer glass 11, 12 are connected with each other The state is arranged face to face, and the space formed between the inner and outer glass 11, 12 constitutes a hollow cavity 15, and the window frame tube 13 is arranged around the peripheral edge of the inner glass 11 and the outer glass 12. The inner and outer glass 11, 12 between, and the window frame pipe 13 forms a window frame lumen 131, and the sealing strip 14 is embedded between the inner and outer glass 11, 12 on the side corresponding to the window frame pipe 13 facing away from the aforementioned hollow cavity 15, by The sealing strip 14 bonds the inner and outer glass 11 , 12 as a whole and simultaneously seals the surrounding edges of the hollow cavity 15 . exist fi...

Embodiment 2

[0034] Not shown in the figure, only the end surface of the air pipe 42 is retracted from the surface of the sealing strip 14 facing outward, and the degree of retraction is less than 2 mm, and the rest are the same as the description of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com