Bundling band disk mechanism

A technology of belt reel and deceleration motor, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of high cost, difficult implementation, inconvenient disassembly and maintenance, and achieve increased expansion and contraction Range, the effect of realizing the expansion and contraction function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

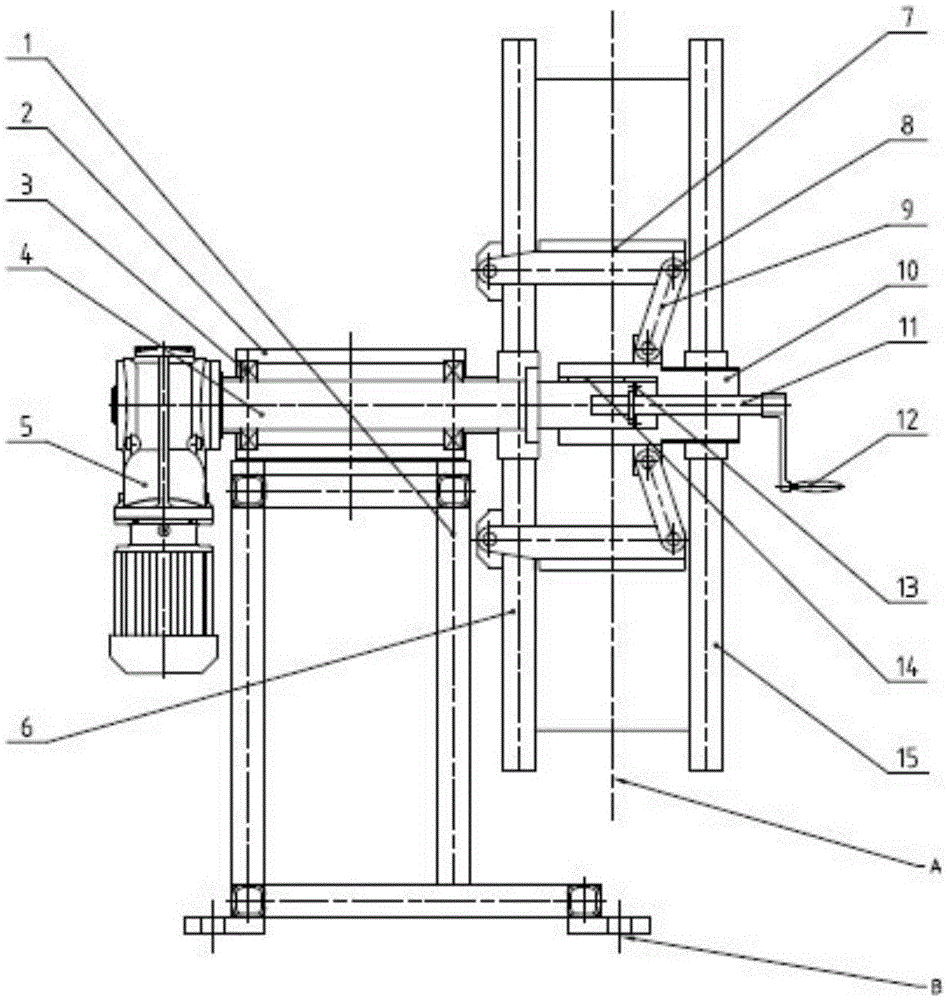

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] Referring to the accompanying drawings, a strapping reel mechanism includes a base 1, a bearing seat 2 is fixed on the base 1, a rotating shaft 4 is supported on a bearing 3 in the bearing seat 2, and the left end of the rotating shaft 4 is connected with a decelerating motor 5, and the decelerating motor 5 The rotating shaft 4 is driven to rotate, and the shaft shoulder of the rotating shaft 4 is connected with the inner guard plate 6. There are no less than two hinged joints on the outer side of the inner guard plate 6, and each hinged joint is hinged with one end of the expansion-contraction plate 7 through a pin shaft 8, and the expansion-contraction plate 7 is hinged. 7 The other end is hinged with one end of the chain plate 9 through the pin shaft 8, and the other end of the chain plate 9 is hinged with the hinge joint above the screw sleeve 10 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com