Single-chain-plate expanding and shrinking mechanism

An expansion and contraction, single-chain technology, applied in the field of single-chain plate expansion and contraction mechanism, can solve the problems of high cost, complex structure, inconvenient disassembly and maintenance, etc., and achieve the effect of realizing the expansion and contraction function and increasing the expansion and contraction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

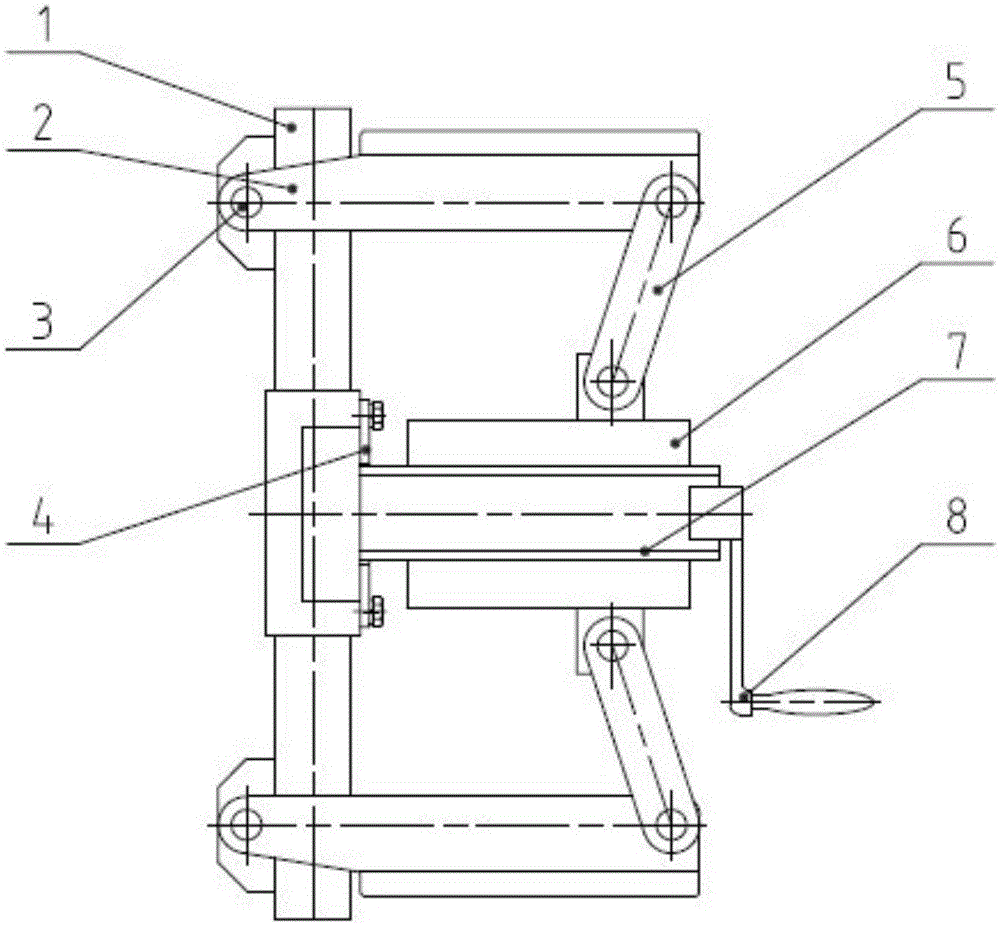

[0012] Referring to the accompanying drawings, a single chain plate expansion and contraction mechanism includes a fixed frame 1, at least two hinges are arranged on the outside of the fixed frame 1, the hinged ports are hinged to one end of the expansion and contraction plate 2 through a pin shaft 3, and the other end of the expansion and contraction plate 2 is hinged. One end of the chain plate 5 is hinged through the pin shaft 3, and only one chain plate 5 is hinged on one expansion and contraction plate 2; the other end of the chain plate 5 is hinged through the pin shaft 3 and the hinge on the screw sleeve 6; the screw sleeve 6 is provided with an internal thread , the screw 7 is provided with an external thread, and the screw sleeve 6 is threadedly matched with the screw 7; one end of the cylindrical head of the screw 7 is embedded in the blind hole at the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com