A kind of pneumatic current receiver at the lower part of the third rail

A current collector and current collector shoe technology, which is applied in the field of pneumatic current collectors at the lower part of the third rail, to achieve good coupling and current collection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

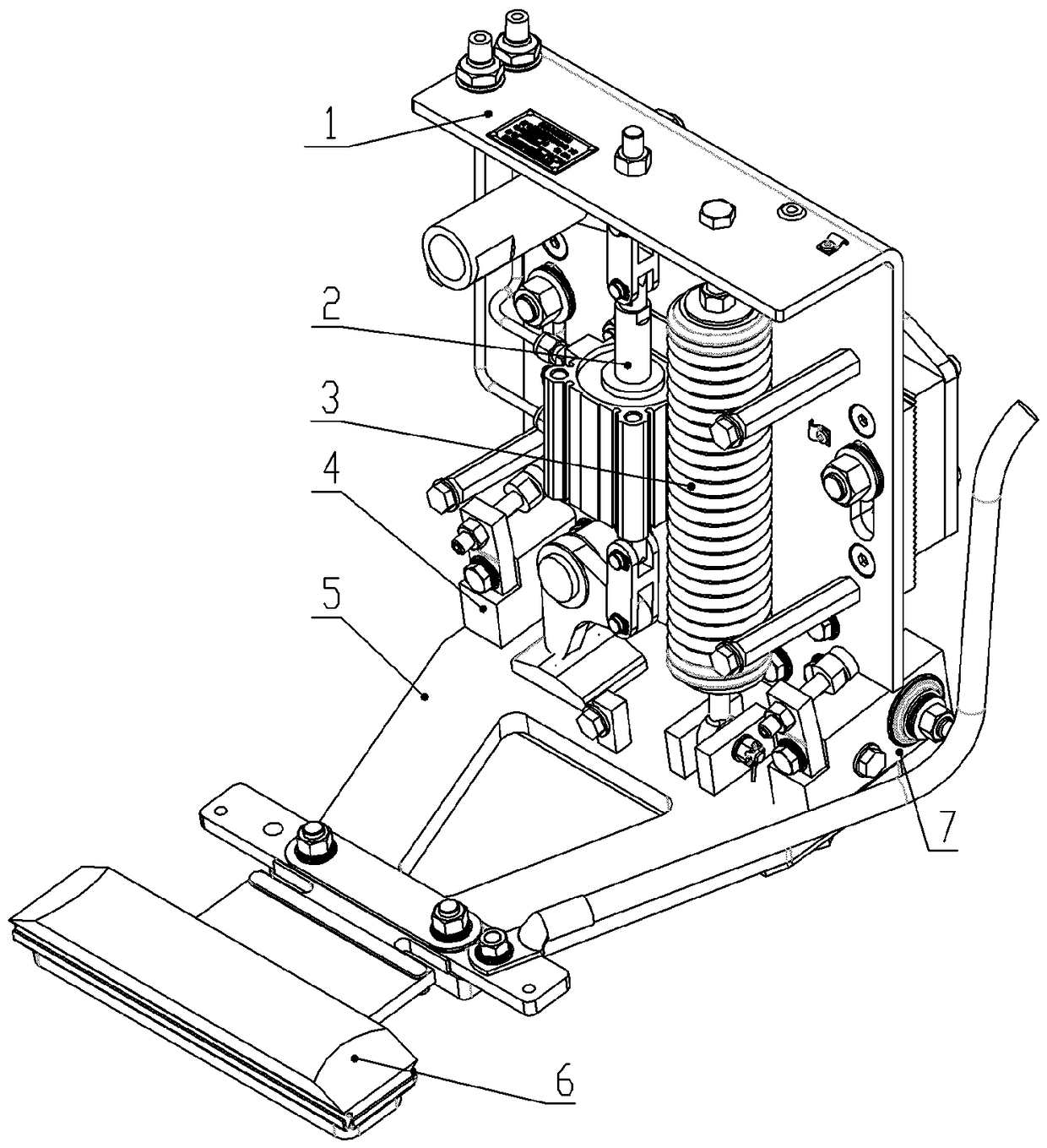

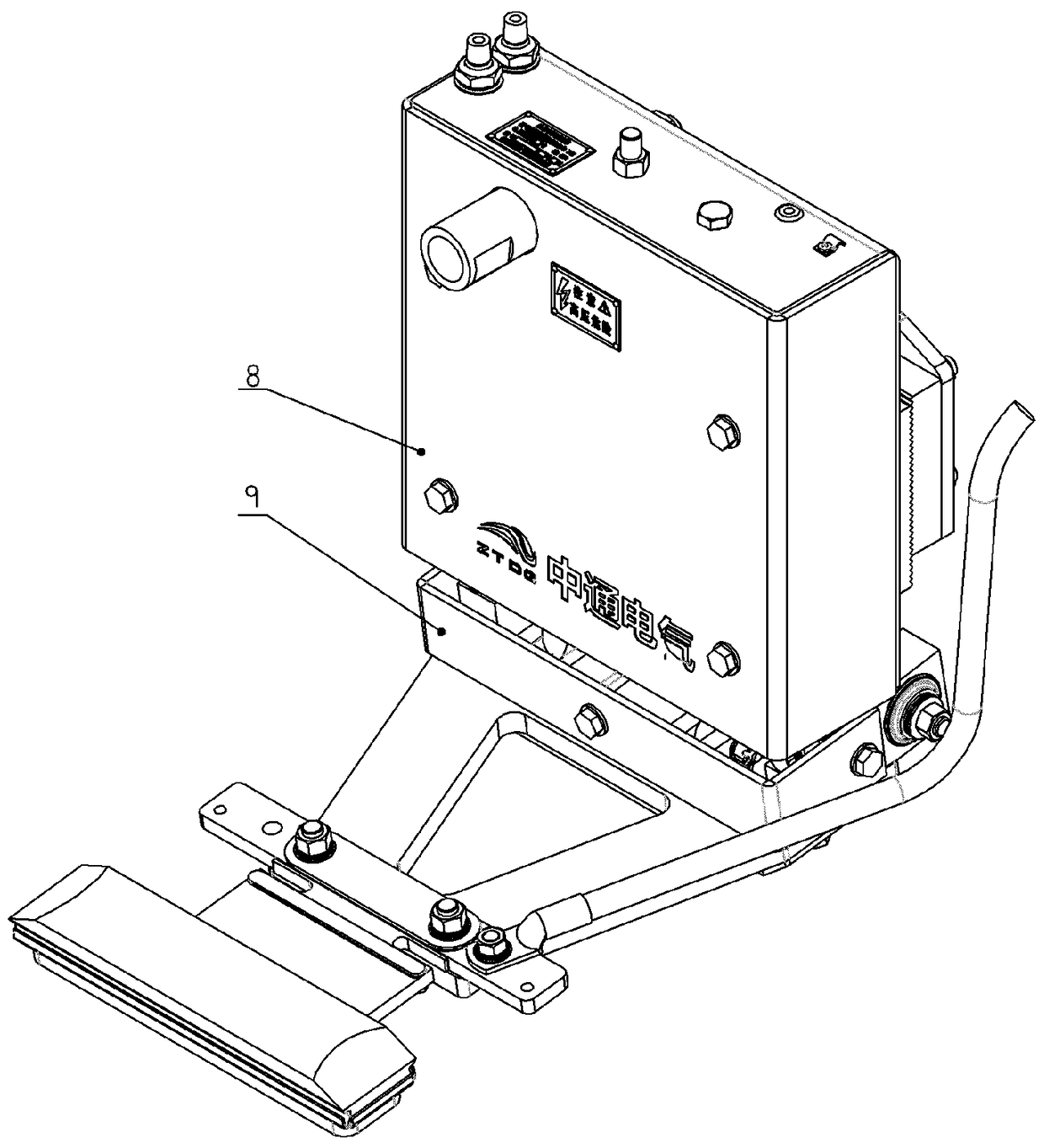

[0019] Embodiment 1, the present invention is installed on the back plate assembly 1, the cylinder and the upper and lower crank connecting rod assembly 2 connected, the tension spring assembly 3, the left and right flexible bearing seats 4 and 7 connected to the swing arm, and the insulating swing arm 5. The flow receiving shoe 6 on the swing arm, the upper insulating shield 8 and the lower insulating shield 9 etc. constitute the lower pneumatic current collector. Cylinder and connected upper and lower crank and connecting rod assembly 2 only need to use a double-acting cylinder, the lower end piston rod of the double-acting cylinder is connected to the shoe-off crank through the connecting rod, and the acting force is on the swing arm to make the swing arm swing downward, so that the flow receiving Pneumatic shoe removal is realized when the sliding shoe is separated from the third rail, or the shoe removal crank does not act on the swing arm and the swing arm swings upward u...

Embodiment 2

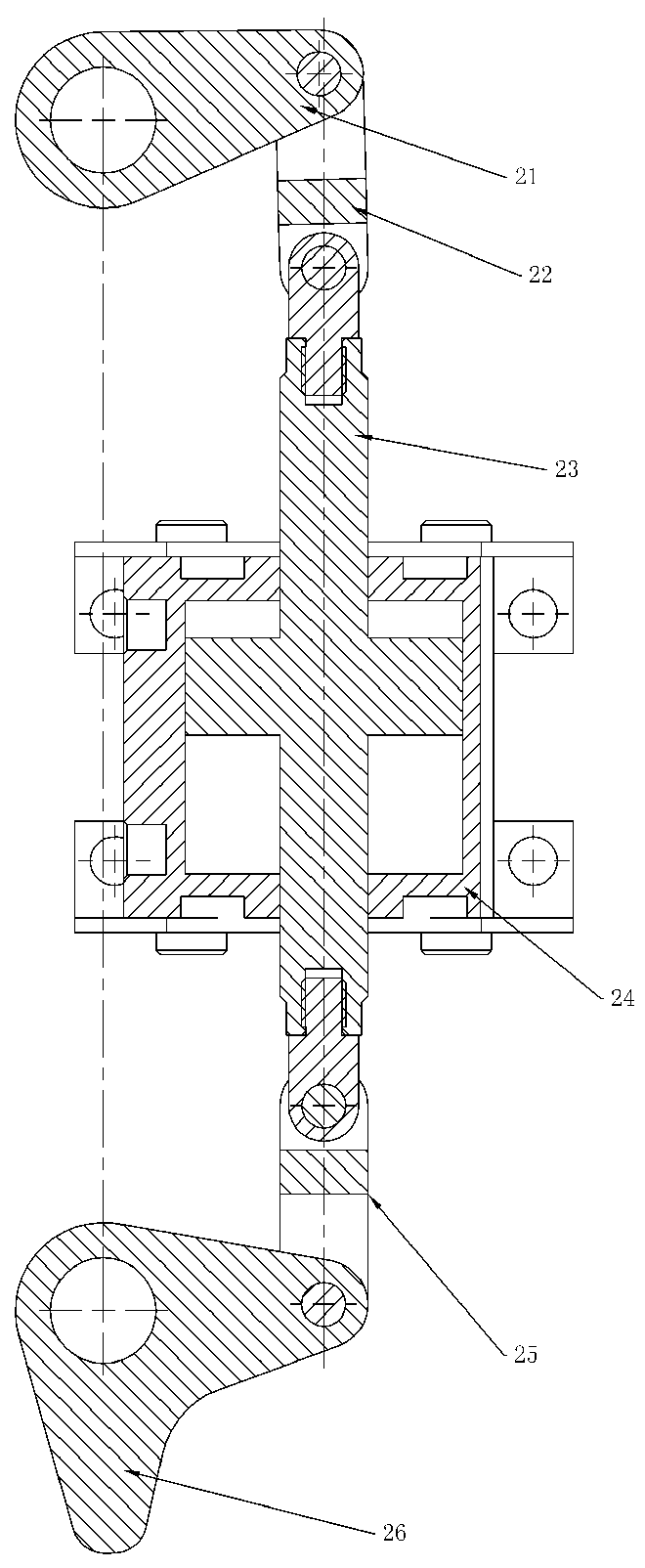

[0020] Embodiment 2, the cylinder of the present invention and the connected upper and lower crank and connecting rod assembly 2. The piston rod at the lower end of the cylinder is connected to the boot-off crank and the manual boot-off crank connected to the upper piston rod. When the boot-off crank makes the swing arm reach the boot-off position At or slightly past bottom dead center. A limit adjustment bolt is set on the top of the manual boot-off crank, and the position can be adjusted slightly so that the boot-off crank can be kept at the bottom dead center or slightly past the bottom dead point, and it can be held against the swing arm to maintain the boot-off position. Close the air source without being in a long-term ventilation working state. refer to figure 1 and Figure 4 , and the rest are the same as Example 1.

Embodiment 3

[0021] Embodiment 3, the left and right flexible bearing seats 4 and 7 connecting the swing arm and the back plate of the present invention adopt rubber elastic bearings, which can connect the swing arm and make the swing arm swing at a certain angle, so that when the current receiver operates normally, the current receiver can be guaranteed Adapt to the irregularity changes of the three rails and the wear changes of the current collector shoes, realize the automatic adjustment of the elastic components of the current receiver, balance and maintain the good coupling and current reception between the current collector shoes and the three rails, and play a role in damping vibrations to highlight its Good dynamic following performance of the receiver. refer to figure 1 and Figure 4 , and the rest are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com