Electromagnetic sucking-disc claw

An electromagnetic chuck and gripper technology, applied in the field of mechanical grippers, can solve problems such as unreasonable structural design of electromagnetic chucks, and achieve the effects of small residual magnetism, low risk, and strong suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

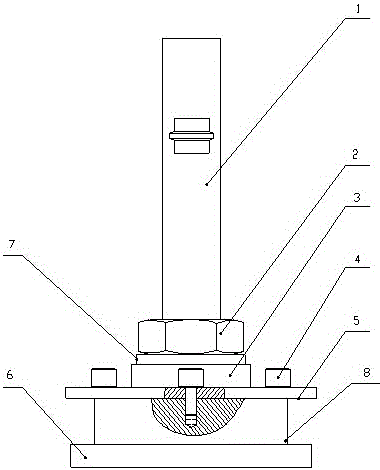

[0016] Such as figure 1 As shown, the present invention discloses an electromagnetic sucker gripper, comprising a handle 1, an insulating plate 5, a connection block 3 connecting the handle 1 and the insulating plate 5, screws 4, a fixing plate 8 and an electromagnetic sucker 6; the electromagnetic sucker gripper There is a pair of grooves on the upper part of the handle 1 for the installation of the external mechanism, which is connected with the connecting plate through the nut 2, a gasket 7 is arranged under the nut 2, and the connecting plate 3 is connected with the insulating plate 5; four screws are evenly distributed on the panel of the insulating plate 5 4. The insulating plate 5 is connected with the fixing plate 8 through the screw 4;

[0017] When in use, connect the handle 1 with the external mechanism, place the whole mechanism on the upper part of the material, move down until the electromagnetic chuck 8 is about to contact the material, absorb the material, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com