Thermal insulation kettle sealing ring and thermal insulation kettle

A heat preservation pot and sealing ring technology, applied in non-pressure containers, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve problems such as hot water spraying, achieve good sealing, and solve the effect of steam or hot water spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

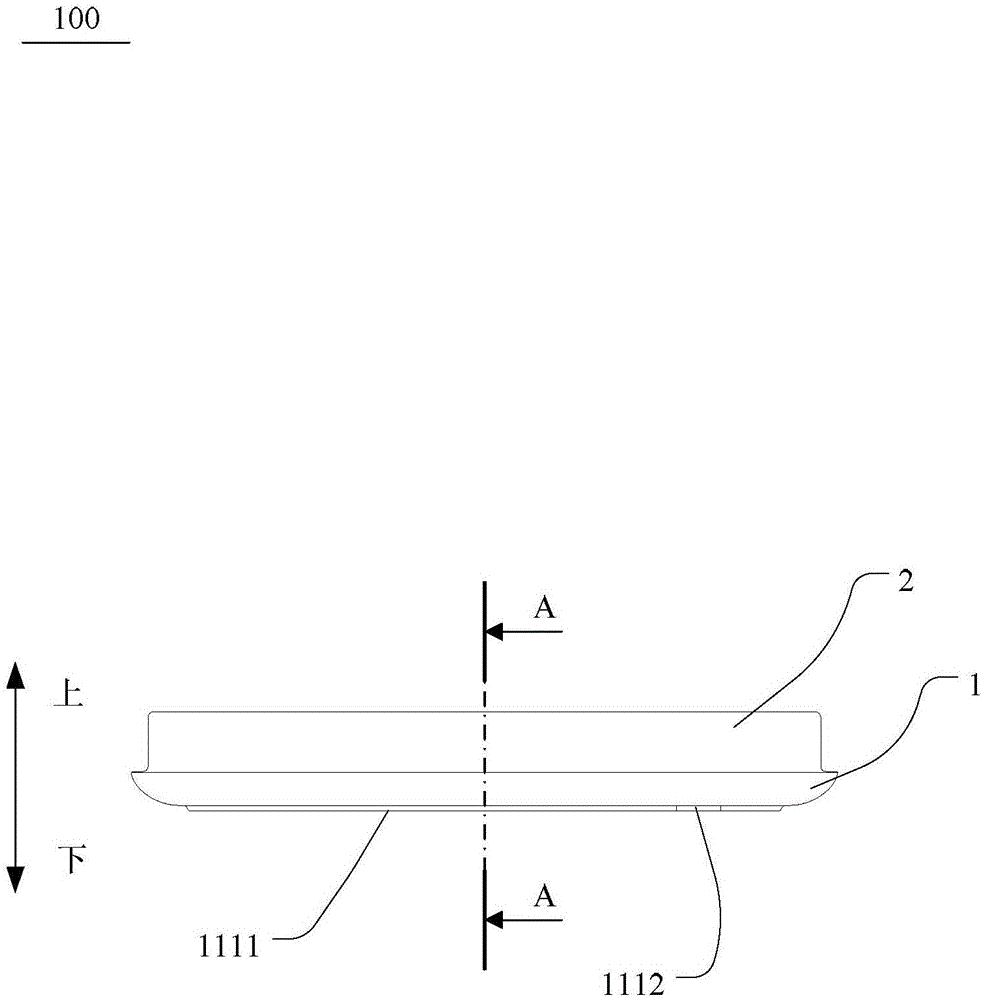

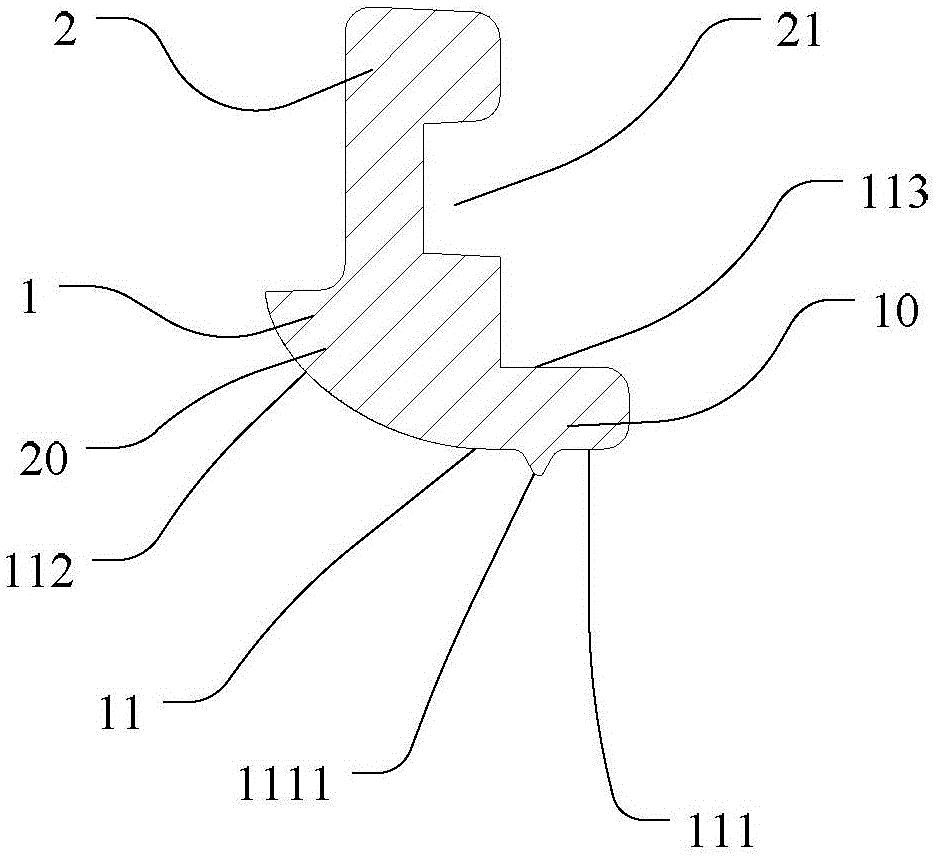

[0022] Description: if Figure 1-3 As shown, the direction facing the annular protrusion 1111 on the sealing ring 100 of the thermos pot is referred to as the downward direction, and the opposite side is referred to as the upper side.

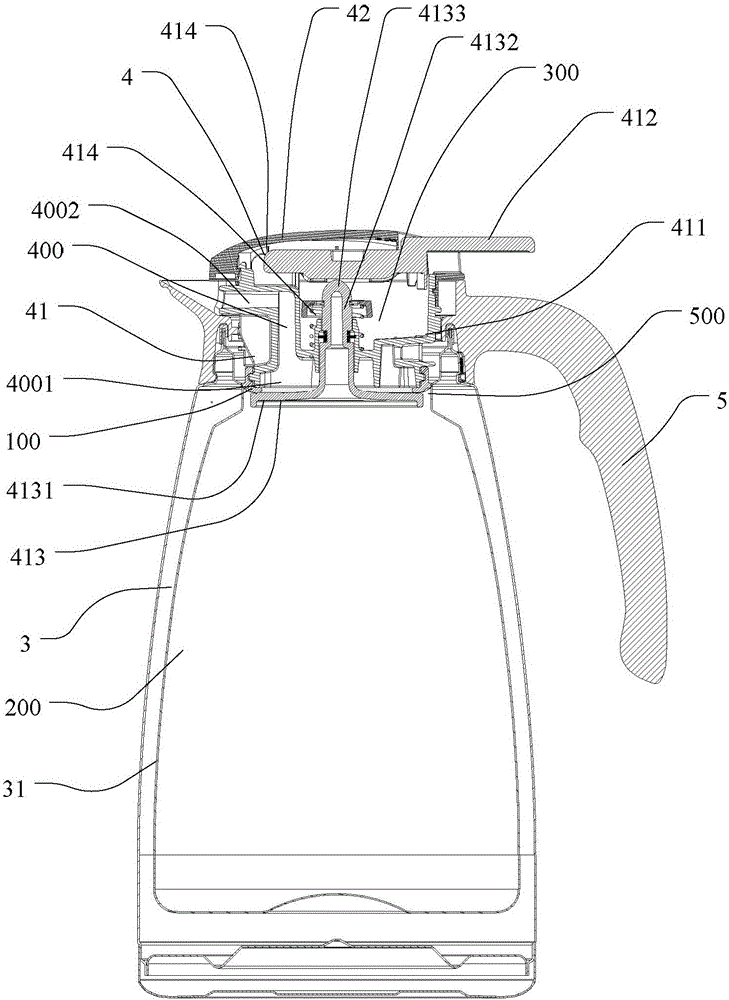

[0023] Such as Figure 1-2 As shown, the insulating pot sealing ring 100 in the present invention includes an annular sealing portion 1 and an annular fixing portion 2, the upper end of the sealing portion 1 is connected to the lower end of the fixing portion 2, and the fixing portion 2 is provided with There is a snap-fit structure 21 for the pot lid assembly 4 (such as image 3 shown) are connected; the sealing part 1 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com