Production technology of oreochromis mossambicus granulated feed

A technology of pellet feed and production process, which is applied in the field of fish feed, can solve the problems that shrimp feed production equipment and technology are not suitable for producing tilapia pellet feed, etc., and achieve the effects of improving palatability, reducing compression ratio, and stabilizing the current of the main machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

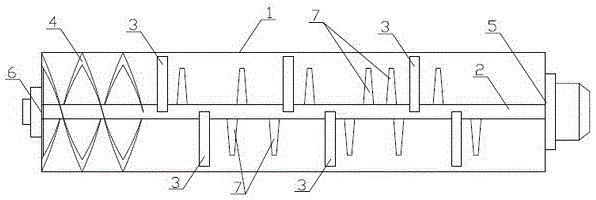

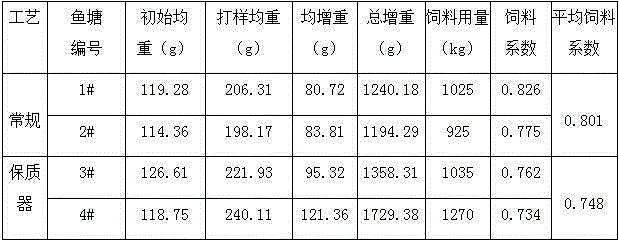

[0029] A production process of tilapia pellet feed, comprising: the raw material of tilapia feed is subjected to a first conditioning treatment by a first conditioner, then continues to be subjected to a quality preservation treatment by a conditioner, and then is subjected to a second conditioning treatment by a second conditioner. Conditioning treatment, and finally enter the pellet mill to obtain tilapia pellet feed; the quality preservation treatment time of the raw materials in the quality preserver is 130 seconds.

[0030] In the basic technical solution of the present invention, other steps of pellet feed production can adopt conventional steps in this field. The process parameters of the first quenching and tempering treatment, the second quenching and tempering treatment, and other process parameters of the quality assurance treatment except time can all adopt conventional processes in the field.

Embodiment 2

[0032] A production process of tilapia pellet feed, comprising: the raw material of tilapia feed is subjected to a first conditioning treatment by a first conditioner, then continues to be subjected to a quality preservation treatment by a conditioner, and then is subjected to a second conditioning treatment by a second conditioner. Conditioning treatment, and finally enter the pellet mill to obtain tilapia pellet feed; the quality preservation treatment time of the raw materials in the quality preserver is 150 seconds.

[0033] In the basic technical solution of the present invention, other steps of pellet feed production can adopt conventional steps in this field. The process parameters of the first quenching and tempering treatment, the second quenching and tempering treatment, and other process parameters of the quality assurance treatment except time can all adopt conventional processes in the field.

Embodiment 3

[0035]A production process of tilapia pellet feed, comprising: the raw material of tilapia feed is subjected to a first conditioning treatment by a first conditioner, then continues to be subjected to a quality preservation treatment by a conditioner, and then is subjected to a second conditioning treatment by a second conditioner. Conditioning treatment, and finally enter the granulator to obtain tilapia pellet feed; the quality preservation treatment time of the raw materials in the quality preserver is 140 seconds.

[0036] In the basic technical solution of the present invention, other steps of pellet feed production can adopt conventional steps in this field. The process parameters of the first quenching and tempering treatment, the second quenching and tempering treatment, and other process parameters of the quality assurance treatment except time can all adopt conventional processes in the field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com