An Optical Fiber Temperature Measuring Structure for 10kv Distribution Transformer

A distribution transformer and optical fiber temperature measurement technology, applied in the field of distribution transformers, can solve the problems of large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiment:

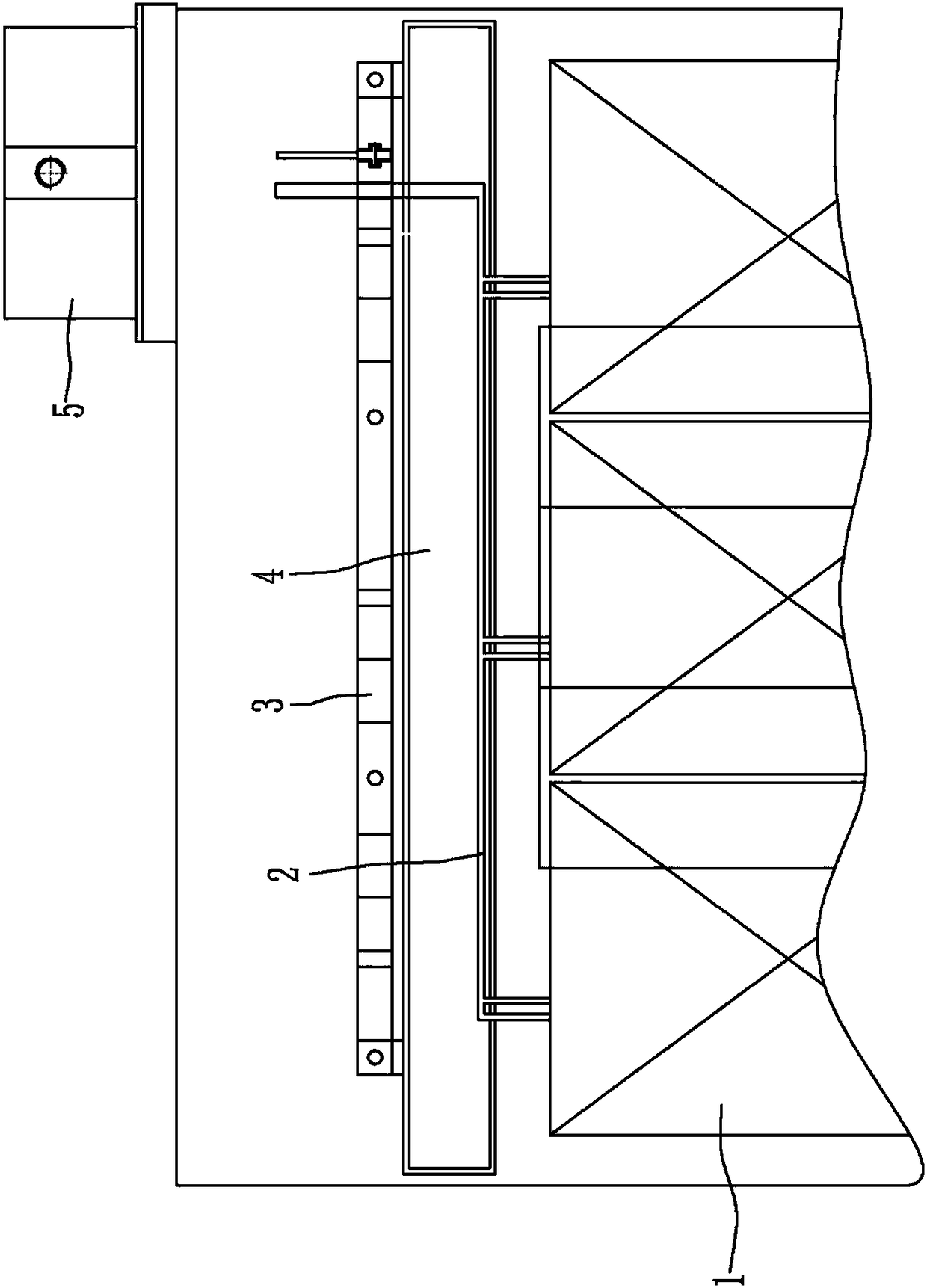

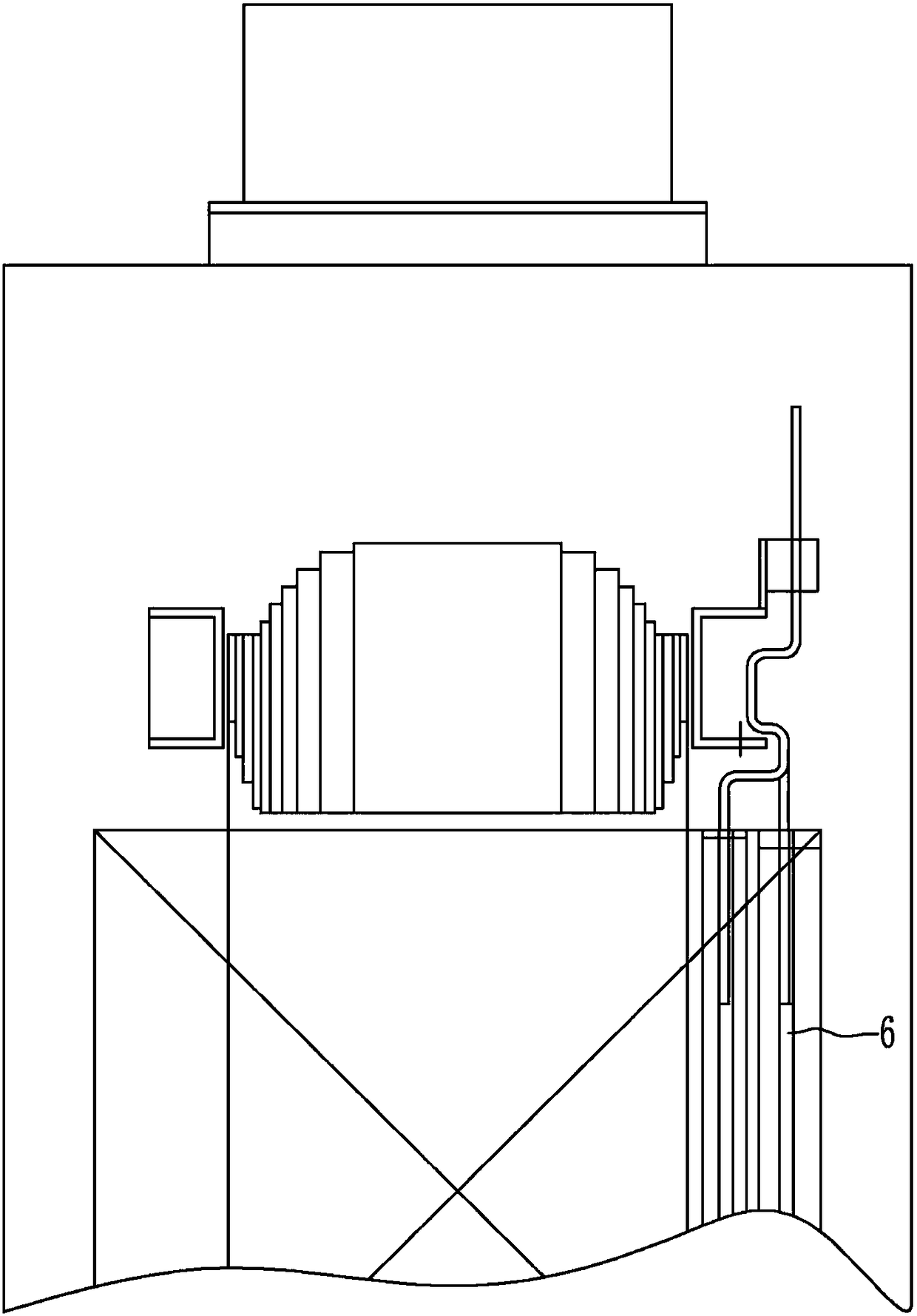

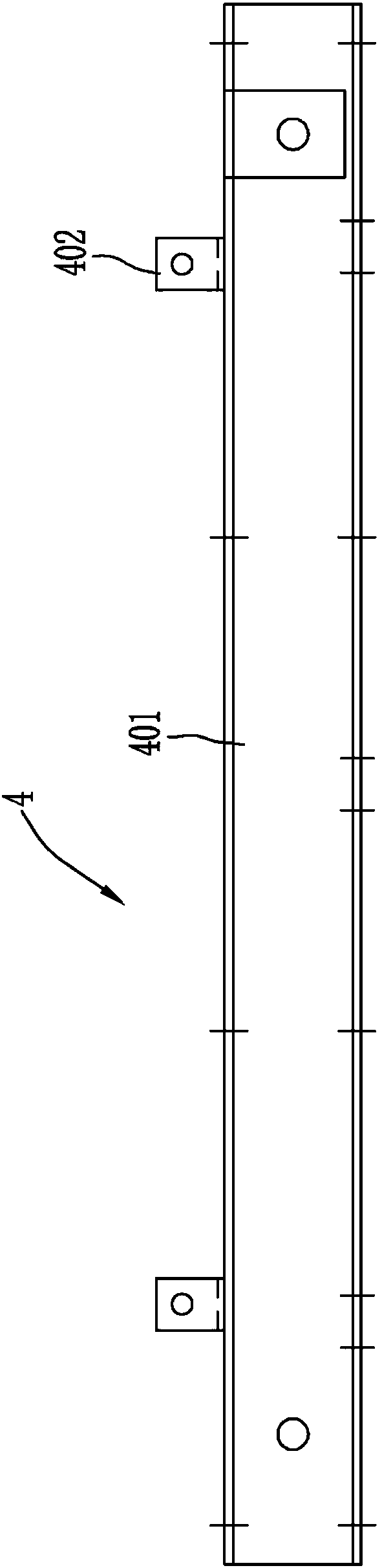

[0018] See attached figure 1 and 2 As shown, an optical fiber temperature measurement structure for a 10KV distribution transformer described in this embodiment includes a high and low voltage winding 1, a sensor oil passage stay 6 installed on the high and low voltage winding 1, and is used to detect high An optical fiber temperature sensor 2 for the inner coil temperature of the low-voltage winding 1, an optical fiber junction box 5 connected to the optical fiber temperature sensor 2 through an optical fiber, a wire clamp 3 for fixing the optical fiber, and a clip 4 for fixing and installing the wire clamp 3. Among them, the low-voltage winding in this scheme adopts a multi-layer cylindrical structure, the oil channel on it is located at 1 / 2 of the overall height of the low-voltage winding, and the sensor oil channel stay is set opposite to the low-voltage outlet; the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com