A multi-discharge pressure rolling rotor compressor

A rolling rotor type, exhaust pressure technology, used in rotary piston machines, machines/engines, rotary piston pumps, etc., can solve the problems of large compressor power consumption, increased cost, complex system, etc., to reduce space occupation , reduce the number, and control the effect of simple logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

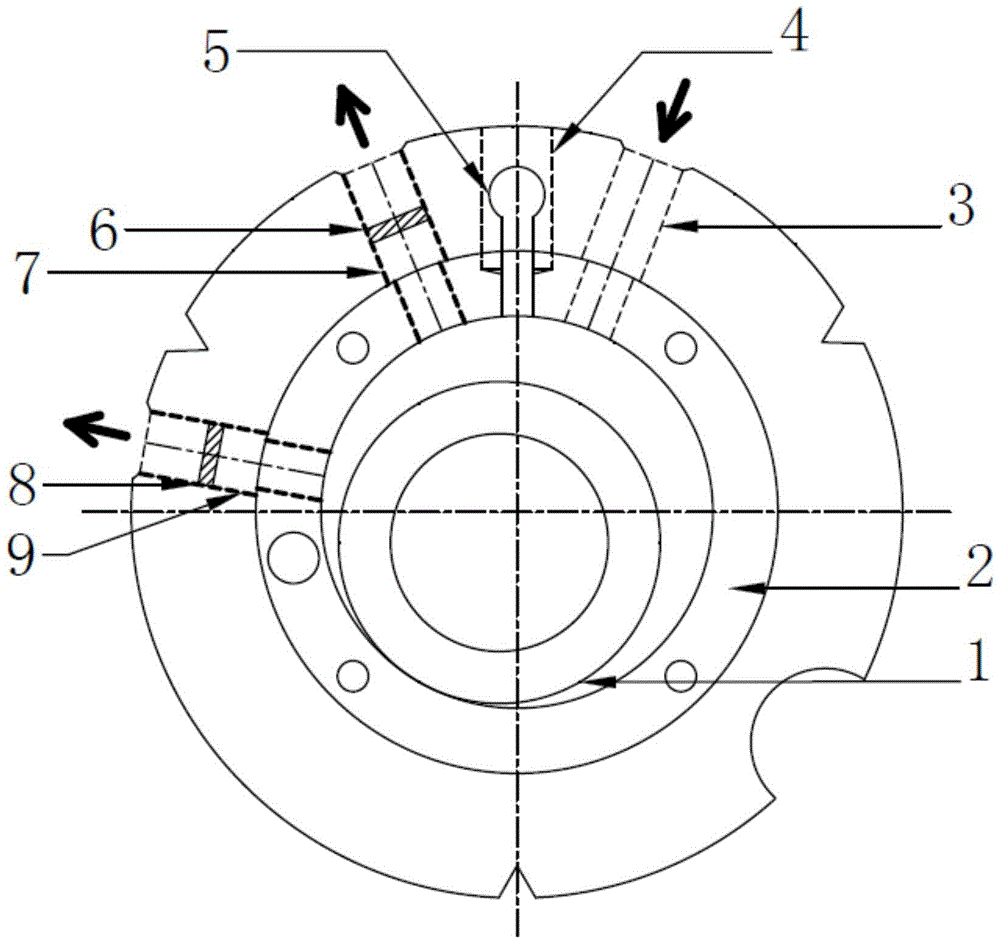

[0024] A dual-exhaust pressure rolling rotor compressor, comprising a cylinder 2 installed in the compressor housing and an eccentric rotor 1 arranged in the cylinder 2. The outer surface of the eccentric rotor 1 and the inner surface of the cylinder 2 form a crescent shape The crescent-shaped space moves with the rotation of the rotor. The cylinder 2 is provided with a reciprocating sliding plate, which is pressed against the outer surface of the eccentric rotor 1 at all times, and divides the crescent-shaped space into a high pressure cavity and a low pressure cavity. The cylinder 2 is provided with an intake channel 3 connected with the low pressure chamber and an exhaust channel connected with the high pressure chamber. There are two exhaust channels, namely a low pressure exhaust channel 9 and a high pressure exhaust channel 7, respectively. The channel 9 and the high-pressure exhaust channel 7 have the same structure. A low pressure exhaust valve 8 is provided in the low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com