Push chain type concrete spraying machine with distributor

A concrete sprayer and push chain technology, which is applied in earthwork drilling, construction material processing, wellbore lining, etc., can solve the problem of not drying the concrete on the chain piston, the local resistance coefficient is large, and the injection hole is easy to rust and other problems, to achieve the effect of good promotion and use value, reduction of loss coefficient, and stable injection effect

Inactive Publication Date: 2015-10-21

李艮

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] 1) Existing technology: the air distribution injection hole is drilled on the cylinder body, and the sharp-edged inlet cylindrical through hole has a large local resistance coefficient and no energy conversion function, resulting in poor injection effect, and the concrete on the chain piston is not easy to clean. Suspension;

[0009] 2) Existing technology: the air distribution injection holes are drilled on carbon steel pipes, and the injection holes are easily rusted, which reduces the injection efficiency;

[0010] 3) Existing technology: the air distribution injection holes are drilled on seamless steel pipes, each drills more than 30 holes, the labor intensity is high, and the manufacturing cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0031] The working principle of the present invention is as follows:

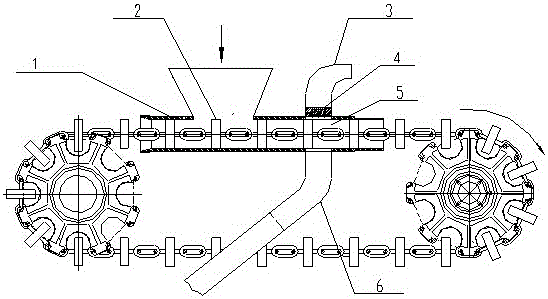

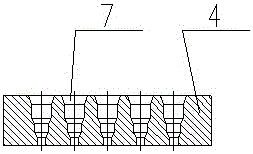

[0032] The mixed concrete is poured into the injection cylinder through the hopper, and the chain piston is driven by the driving sprocket to push it to the mixing chamber. Injection elbow to realize three-phase flow injection.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Provided in the invention is a push chain type concrete spraying machine with a distributor. The spraying machine comprises a chain type piston, an injection cylinder, a high-pressure pipe, a mixing chamber, and a spraying elbow. The mixing chamber is arranged in the middle of the injection cylinder; and the chain type piston penetrates the injection cylinder. The machine is characterized in that a distributor is arranged above the mixing chamber; the high-pressure pipe is connected to the top of the distributor; the spraying elbow is linked below the mixing chamber; air injection holes are formed in the middle of the distributor and the lower ends of the air injection holes are opposite to the upper space of the chain type piston in the mixing chamber, so that attachments of the chain type piston can be cleaned. The distributor is arranged on the mixing chamber; the high-pressure pipe is arranged on the distributor; the chain type piston passes through the injection cylinder; and compresses air is processed by flow acceleration of the distributor and thus the concrete is blown to the spraying elbow. Compared with the prior art, the spraying machine has the following beneficial effects: with the reducing injection pipe type distributor, the outlet injection speed of the compressed air is improve, thereby enhancing the injection capability; a problem that hanging materials can not be blown completely by the chain type piston can be solved; and the machine has the great popularization value.

Description

technical field [0001] The invention relates to engineering machinery equipment, in particular to a push-chain type concrete sprayer with an air distribution seat which integrates conveying, pouring and tamping into one process. Background technique [0002] The push chain concrete sprayer with air distribution seat has a wide range of applications, and its application range is as follows: [0003] 1. Underground engineering: mine shafts, traffic tunnels, water conservancy culverts and various chambers; [0004] 2. Thin-walled structural engineering: thin-shell roofs, building construction, storage warehouses, etc.; [0005] 3. Repair and reinforcement works: reinforcement and repair of bridges, highway slope protection, seawalls and dams; [0006] 4. Refractory and protective engineering: construction and repair of thermal furnaces. [0007] At present, a large number of rotor-type concrete sprayers in use in China have been banned in mines due to reasons such as low ser...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21D11/10E04G21/02E02D15/02

Inventor 李德安王德玲李铭李青李艮王子木李宗远

Owner 李艮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com