Trailer bogie

A technology for bogies and trailers, applied in the field of trailer bogies, which can solve the problems of inconvenient installation and disassembly of magnetic rail hangers, small space, and difficulty in making magnetic rail hangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

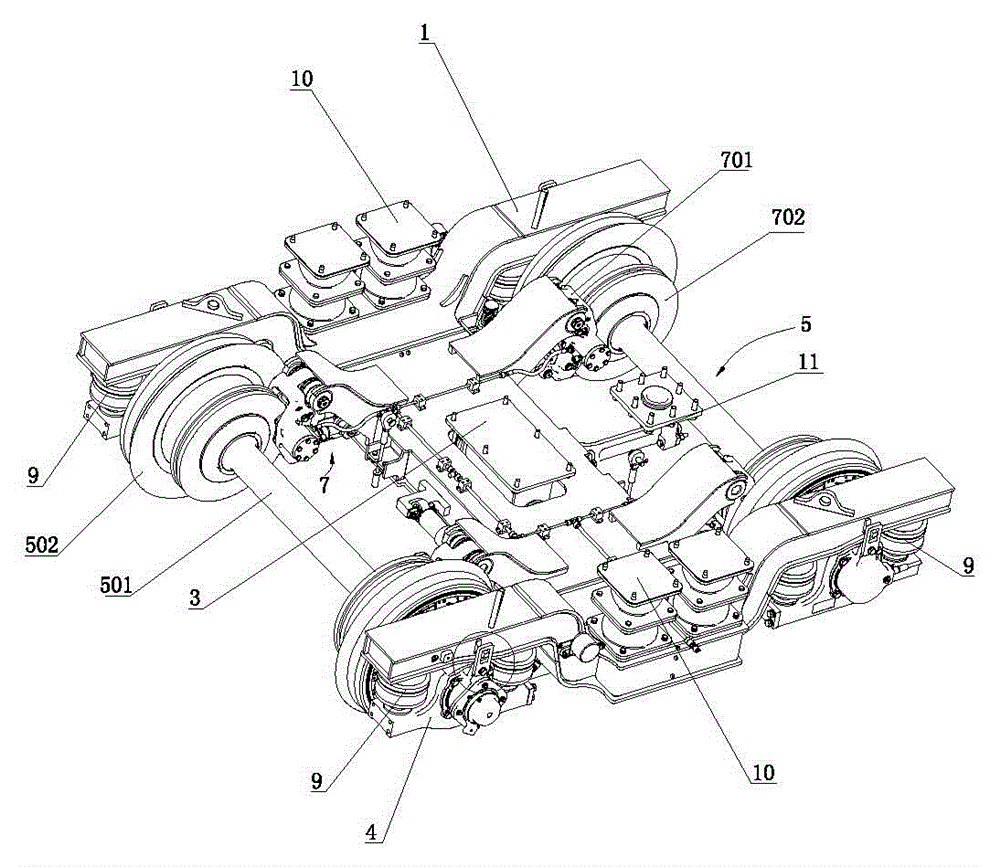

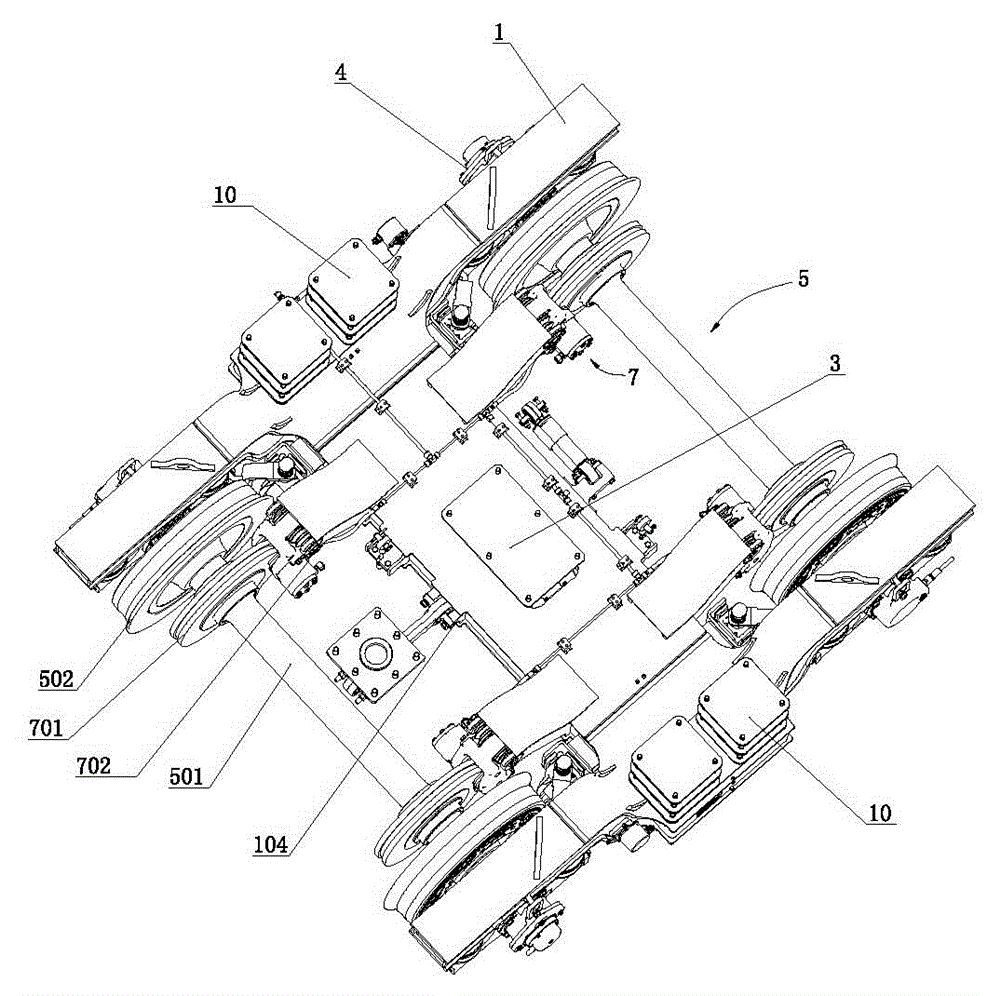

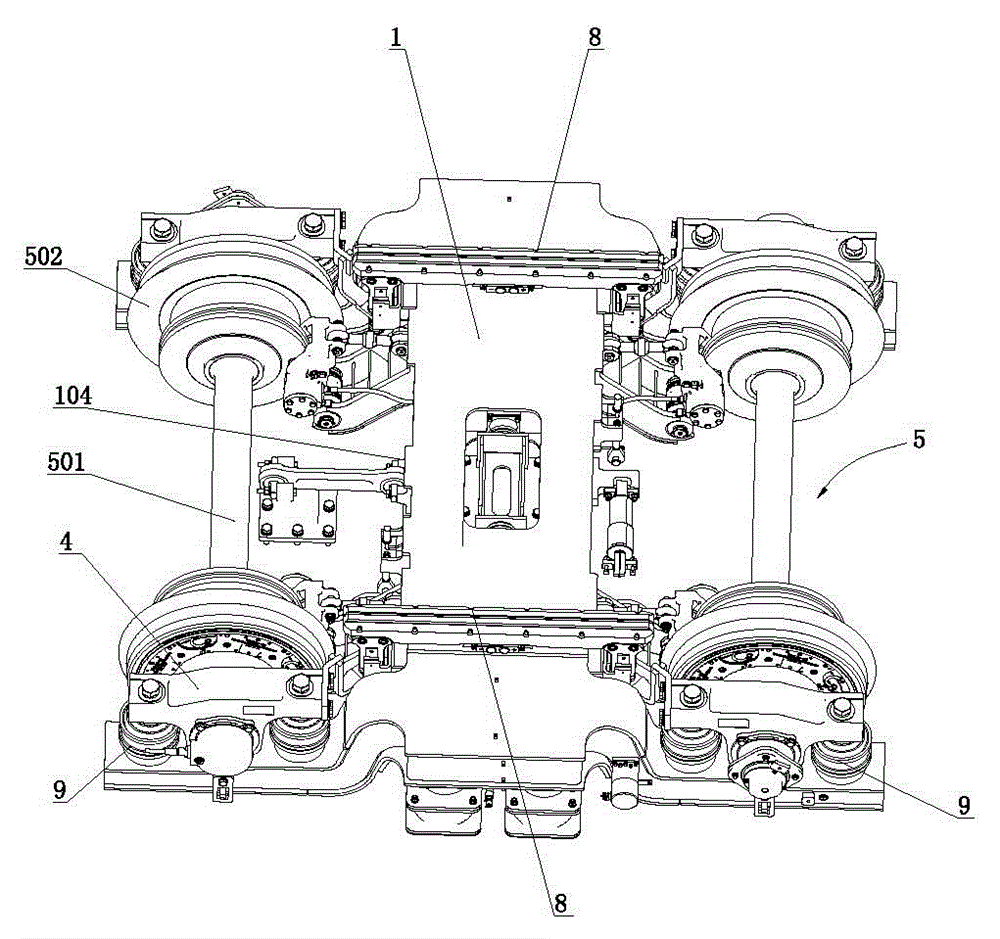

[0034] Such as Figure 1 to Figure 6 As shown, the trailer bogie includes a frame 1, a transverse stop seat 3, an axle box 4, a wheel set 5, a braking device 7, a magnetic rail braking device 8, a primary suspension 9, a secondary suspension 10, and a traction device 11.

[0035] Such as Figure 7 to Figure 9 As shown, the frame 1 includes side beams 101 and cross beams 103 .

[0036]Side beam 101 is made up of two, and is parallel to each other, and described side beam 101 is formed box-shaped structure by base plate, cover plate, side plate and end plate, can reduce the weight of side beam, in by base plate, cover plate, side plate Ribs can be welded in the side sill formed by the end plate to improve the strength of the side sill 101; as Figure 7 As shown, the middle part of the side beam 101 is depressed downward to form a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com