Manufacturing method for posterior column lag screw 3D navigation module used for acetabulum fracture

A navigation module and fracture model technology, applied in the field of fracture reduction, can solve problems such as mismatch and reduced navigation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

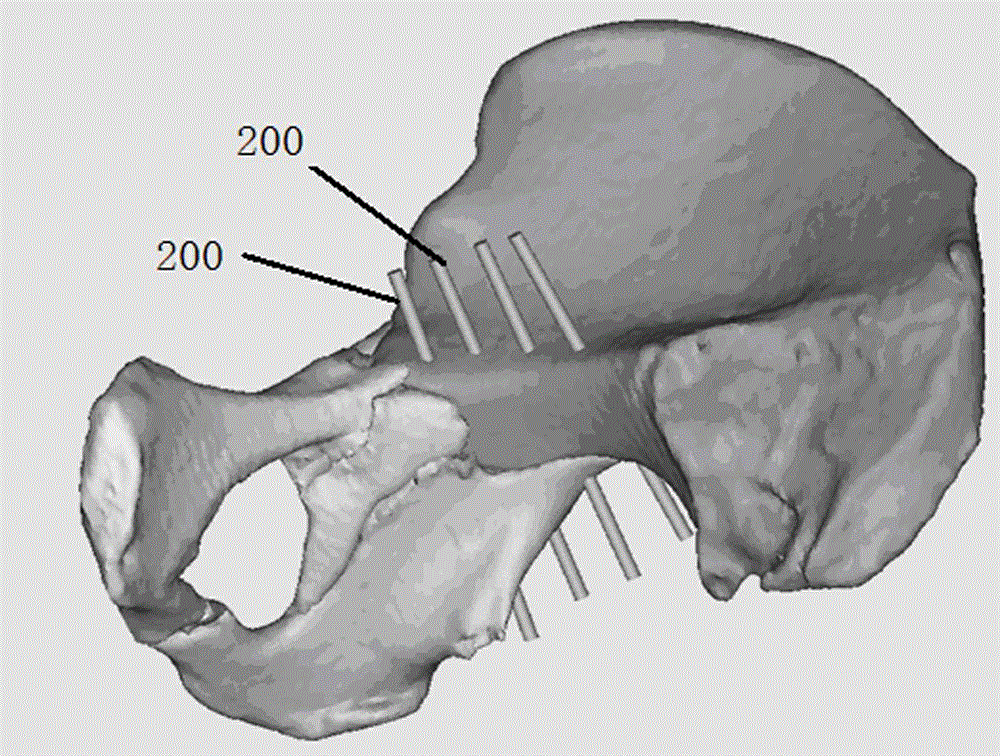

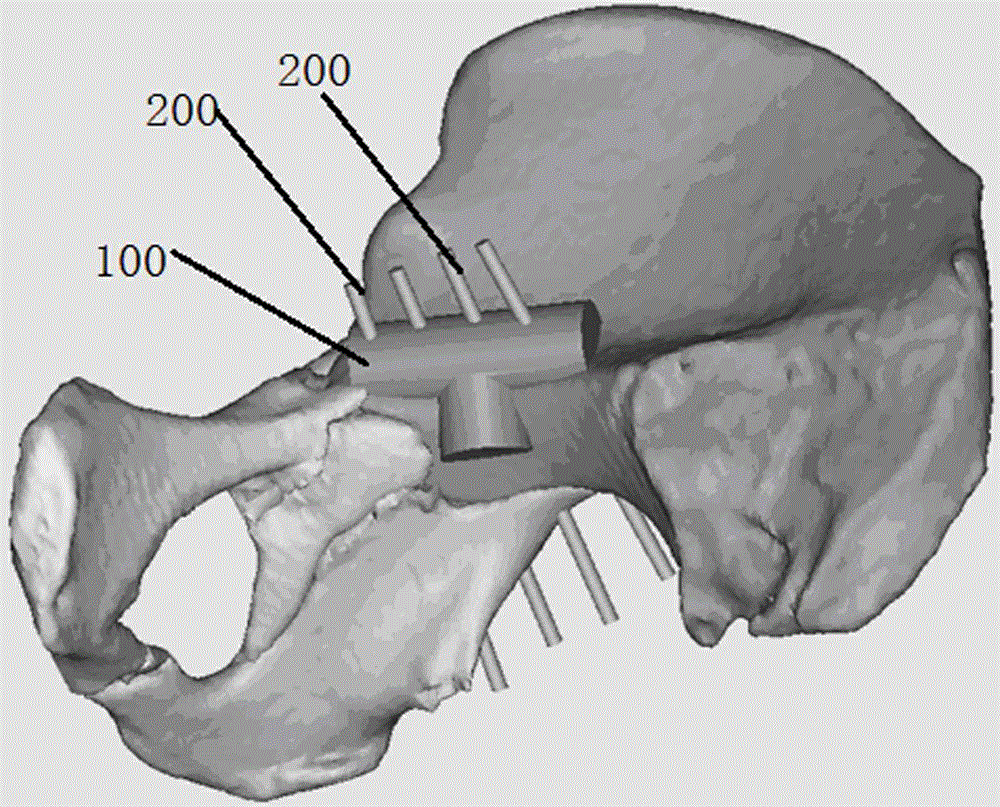

[0038] A method for preparing a posterior column lag screw 3D navigation module for acetabular fractures is carried out through the following steps.

[0039] A. Simulation reconstruction.

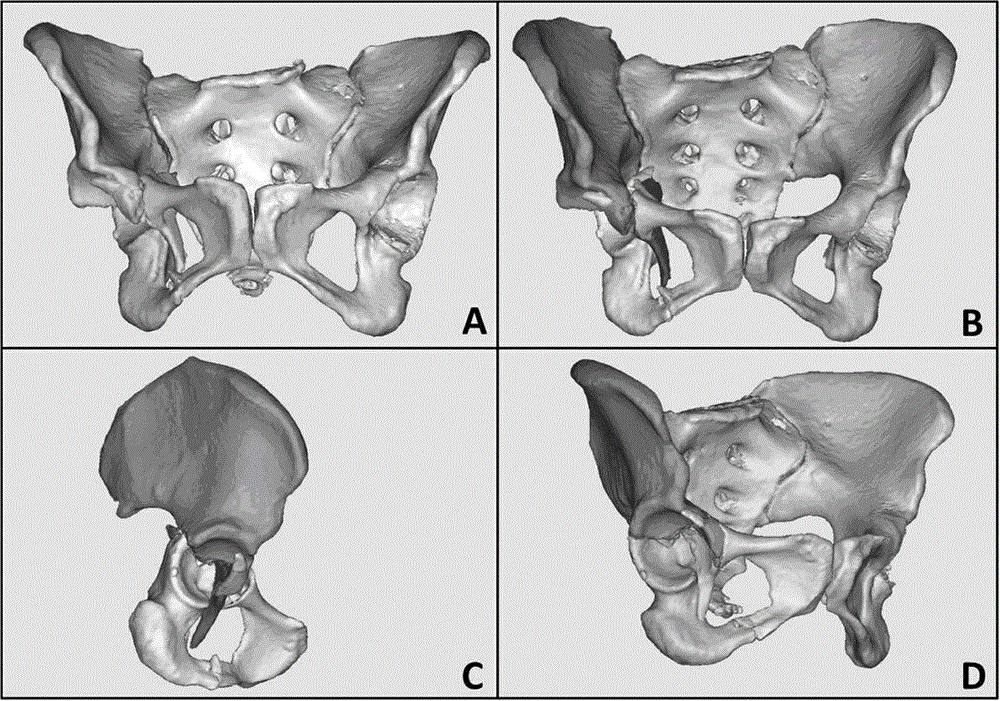

[0040] The original three-dimensional reconstruction model was obtained by three-dimensional reconstruction based on the thin-section CT scan data of the pelvis of the subject with acetabular fracture. Specifically, under the scanning conditions that the scanning layer distance is ≤1mm, the scanning current is 200-250mAs, the scanning voltage is 80-130kv, the scanning matrix is 521×512, the scanning window level is soft tissue window, and the scanning site is the pelvis and upper femur, the hip can be obtained by scanning. Thin-layer CT scan data of the pelvis of the subjects with acetabular fractures, and the original 3D reconstruction model was obtained by performing 3D reconstruction with the medical 3D reconstruction software Mimics14.0.

[0041] On the basis of the original 3D reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com