Electrical connector and method for manufacturing electrical connector

An electrical connector and adjacency technology, which is applied to the parts, connections, circuit/collector parts of the connecting device, etc., can solve problems such as complex methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

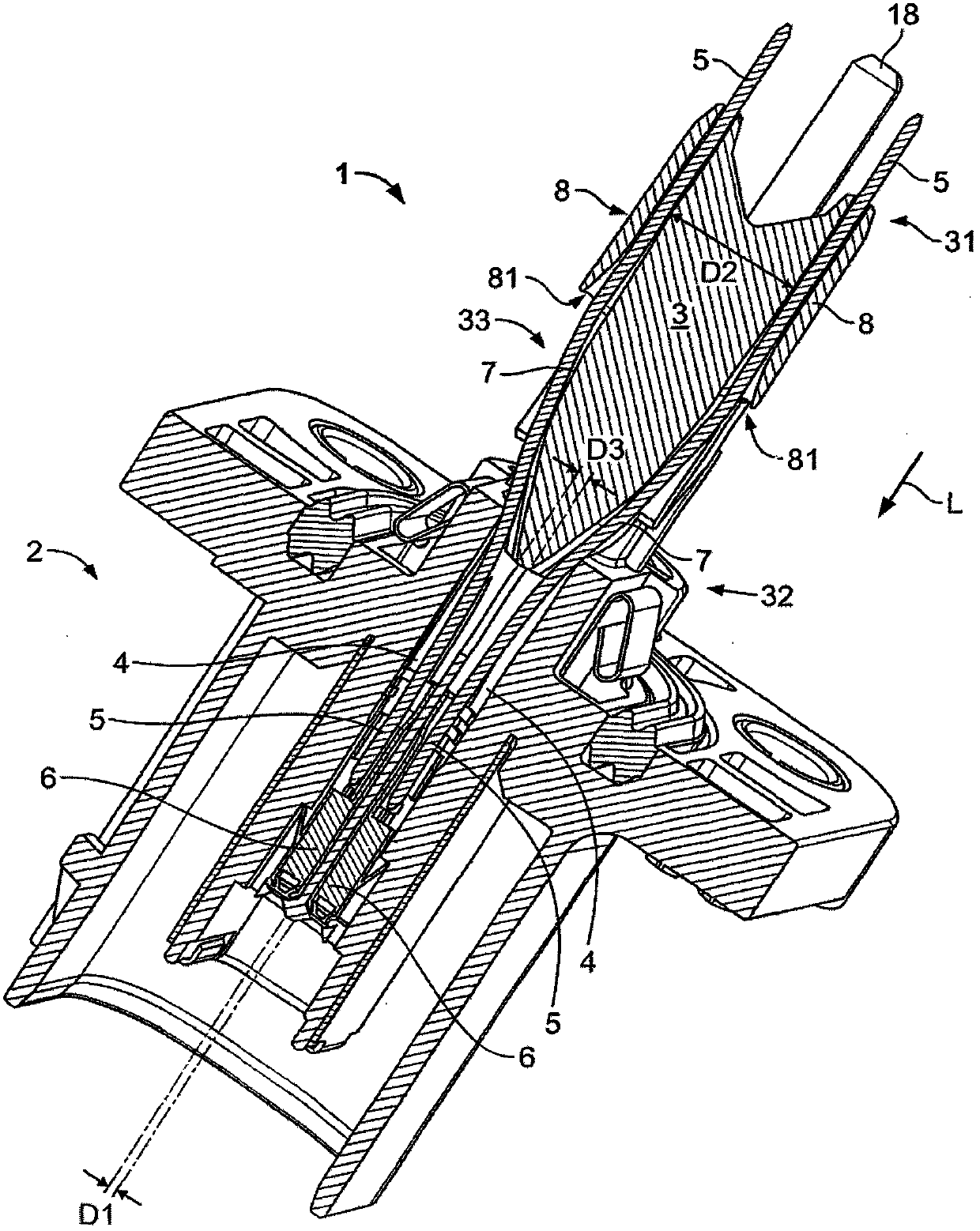

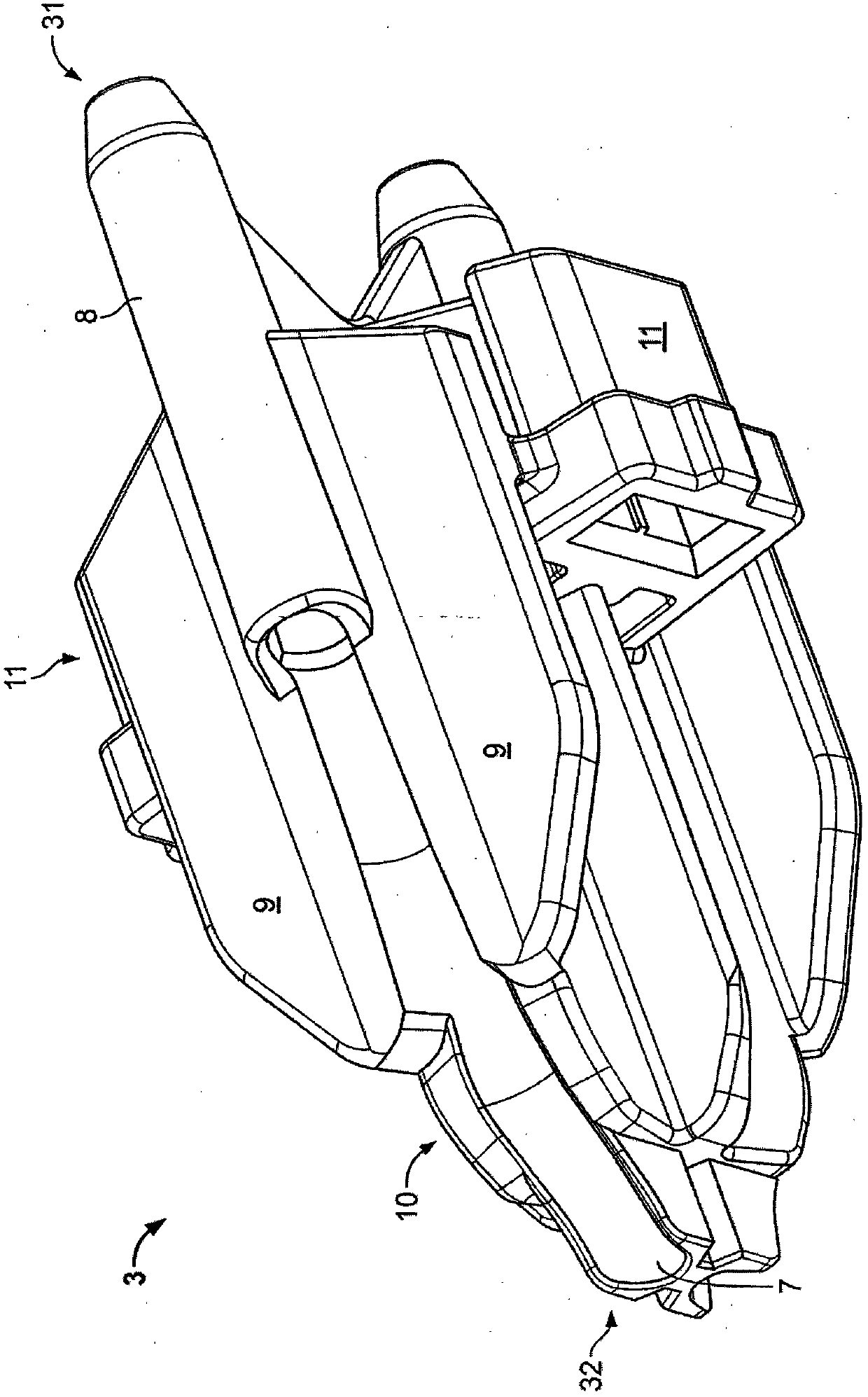

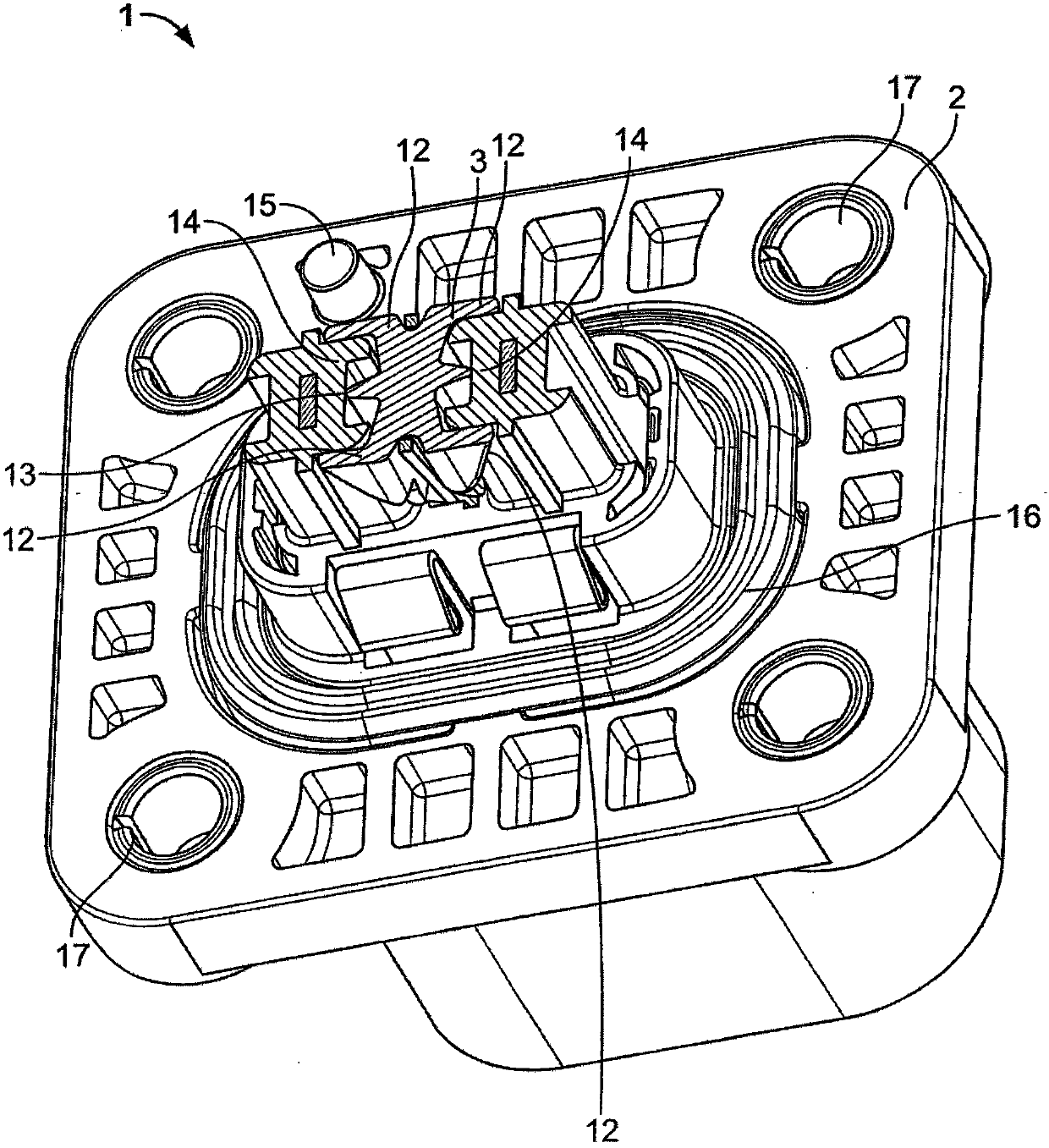

[0032] figure 1 An electrical connector 1 according to the invention is shown. It comprises a housing part 2 and an expansion part 3 .

[0033] In the housing part 2 there are two guide channels 4 for each contact element 5 . The contact elements 5 are designed as substantially rigid pins or pins and have a certain elasticity.

[0034] At the end of the contact element 5 arranged in the housing part 2, a terminal 6 in the form of a socket is mounted so that contact with a mating connector can be made in a simple manner. Alternatively, pin contacts can also be provided, for example. When it is not necessary to form a connection by plug-in, the contact element 5 can be fixed to the further conductor, for example by crimping or soldering.

[0035] The guide channels 4 extend in a linear manner and are parallel to each other in the longitudinal direction L through the housing part 2 .

[0036] The contact element 5 extends out of the housing part 2 and continues along the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com