Z-axial 128-pole magnet ring

A technology of polar magnetism and magnetic poles, which is applied in the field of magnetic ring encoders, can solve the problems of only electronic Z phase, no calibration, loss of signal, etc., and achieve the effects of reducing production costs, low magnetic permeability, and uniform magnetic poles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

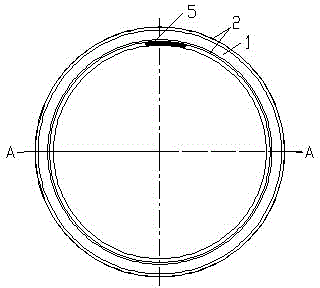

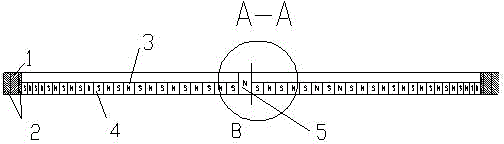

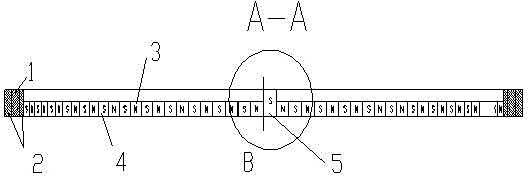

[0020] The 128-pole magnetic ring with Z direction of the present invention includes a ring-shaped base layer 1, a ferrite layer 2 injection-molded on the base layer 1, and 64 pairs of NS magnetic poles are magnetically arranged in sequence on the inner ring of the base layer 1. The 64 pairs of NS poles include 64 N single poles 3 and 64 S single poles 4 . The present invention has adopted 5 embodiments, and embodiment is as figure 2 As shown, the marked magnetic pole is composed of one N single magnetic pole in 64 pairs of NS magnetic poles. Example two such as image 3 As shown, the marked magnetic pole is composed of one S single magnetic pole among 64 pairs of NS magnetic poles. Embodiment three such as Figure 4 As shown, the marked magnetic poles are composed of one S single magnetic pole and one N single magnetic pole among 64 pairs of NS magnetic poles. Embodiment four such as Figure 5 As shown, the marked poles are composed of 64 pairs of NS poles, two N single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com