Material mechanical testing machine capable of performing stretching, compressing, shearing and bending tests

A bending test and material mechanics technology, applied in the direction of analyzing materials, measuring devices, scientific instruments, etc., can solve the problems of cumbersome maintenance and high purchase cost, and achieve the effect of low purchase cost, easy use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below according to the drawings and embodiments.

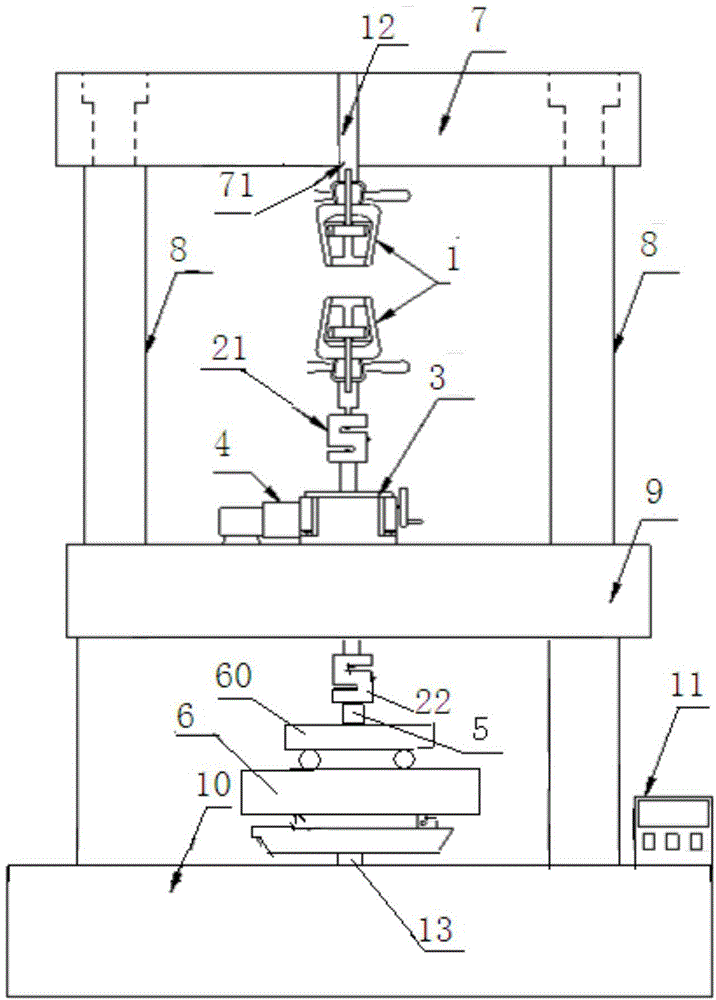

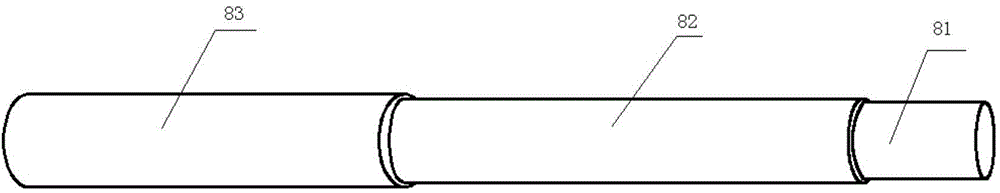

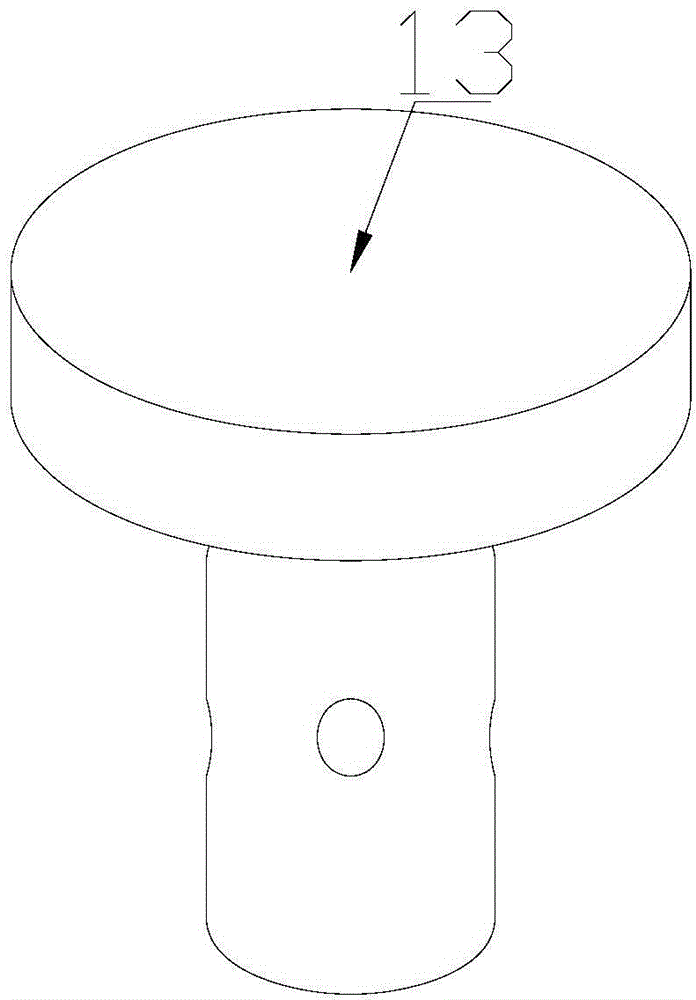

[0017] refer to Figure 1-Figure 3 , the present invention, the material mechanics testing machine that can carry out tension, compression, shearing and bending test, comprises: upper beam 7, middle support beam 9, base 10, two columns 8, hand-operated worm gear booster mechanism 3, two A tensile test fixture 1, a bending test indenter 5, a slider support 6 with an adjustable span for the bending test, the above-mentioned upper beam 7, the middle support beam 9, and the base 10 are arranged in parallel from top to bottom in sequence, and the above-mentioned two columns 8 are arranged on both sides of the row, all passing through the above-mentioned middle support beam 9, the top and the bottom are respectively connected to the above-mentioned upper beam 7 and the above-mentioned base 10, the above-mentioned hand-operated worm gear booster mechanism 3 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com