Method for measuring plane mirror absolute surface shape based on conjugate difference method

A technology for measuring planes and plane mirrors, applied to measuring devices, instruments, and optical devices, etc., can solve problems such as high environmental conditions, complicated testing process, and inability to eliminate system errors, so as to simplify experimental operations and improve inspection accuracy , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

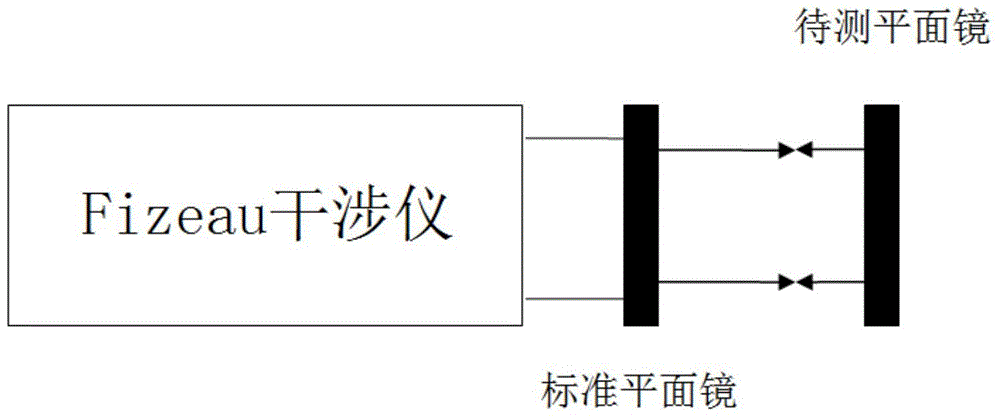

[0039] Taking the Fizeau interferometer as an example, the absolute surface shape of the plane mirror to be measured is measured according to the method of the present invention.

[0040] 1. Measuring devices such as figure 1 Align the standard lens and mount knobs as shown:

[0041] (1) Open the Fizeau interferometer application;

[0042] (2) Install the standard flat mirror: put the two probe angles on the lens frame into the groove of the interferometer bayonet bracket, rotate the lens clockwise, and then tighten it;

[0043] (3) Adjust the standard plane mirror: Press the "Adjustment / Test" button on the remote control to switch the display screen to the "Adjustment" state, and a crosshair image appears on the plane. Adjust the knob of the interferometer bayonet bracket until the bright spot on the screen is in the middle of the crosshairs;

[0044] (4) Place the plane mirror under test on the five-dimensional adjustment frame, and adjust the knob of the adjustment frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com