Jet Studio Translation Multi-Mold Casting Room

A studio and casting well technology, applied in the field of aluminum alloy smelting, can solve the problems of staying in small batch production and influence, and achieve the effect of increasing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings.

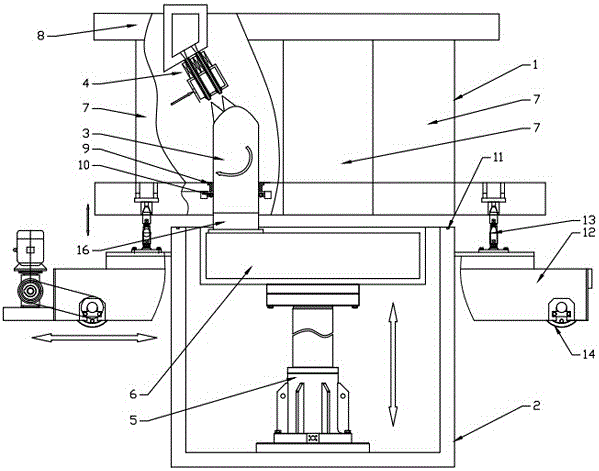

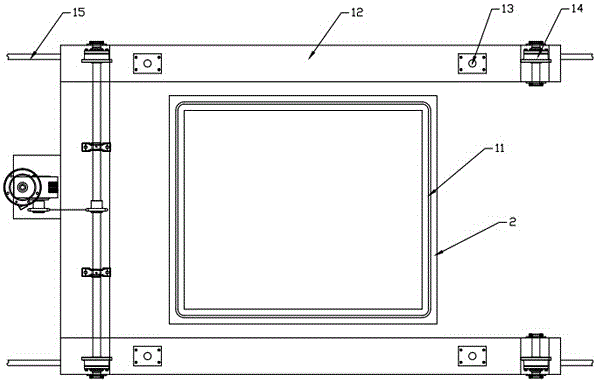

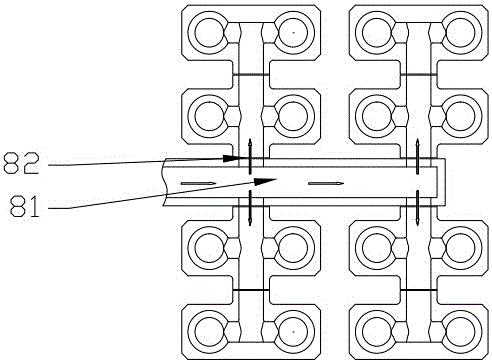

[0017] Such as Figure 1-3 Shown, the injection working chamber translational multi-mode casting room provided by this embodiment includes a casting tray 1 and a casting well 2, a high-speed injector assembly 4 is provided in the casting tray 1, and a lifting cylinder is provided in the casting well 2 5 and the dummy platform 6 that moves up and down with the lifting cylinder, the dummy platform 6 is provided with a plurality of independent dummy ring seats 16 that can rotate 360° in the horizontal direction, and the casting disc 1 is located on the horizontal ground , the casting well 2 is located under the horizontal ground, a seal 11 is provided between the casting plate 1 and the casting well 2; a casting mold ring 9 and a locator used in conjunction with the casting mold ring are provided at the bottom of the casting plate 1, so The casting disc 1 is divided into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com