Processing method for preserved litchis

A processing method and technology of lychee pulp, which are applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of backward processing technology, poor sanitation quality, browning and rotten deterioration, etc., and achieve good market prospects and sales prospects, Solve the effect of short shelf life and lychee fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

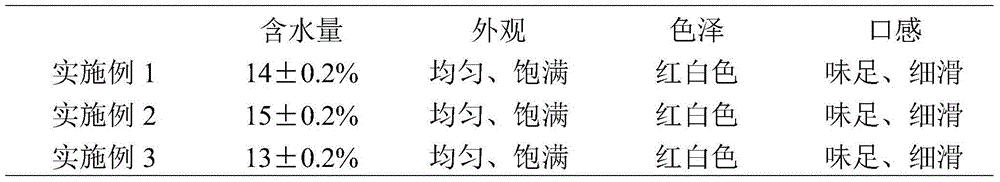

Embodiment 1

[0024] Embodiment 1, choose ripe, fresh " concubine laughs " lychee 10Kg, " concubine laughs " lychee flesh is thick, and core is small, is particularly suitable for making lychee meat jerky, also can shape after drying without filling. After treatment, the jerky has a good plumpness and is in the shape of "lantern meat". The sweet and sour taste is suitable, and the lychee fragrance is full. Lychee pulp is obtained by washing, peeling, and pitting the lychees, and the lychee pulp is guaranteed to be intact and not damaged. To harden the lychee pulp, put the lychee pulp into 0.2% NaHSO 3 , 0.1% citric acid, 0.2% CaCl 2 Soak in the aqueous solution for 2 hours; the hardened lychee pulp can keep the shape in the subsequent saccharification and drying, and ensure the smooth processing of preserved fruit. To scald the hardened lychee pulp, put the hardened lychee pulp into hot water at 80°C for 3 minutes; take it out and drain at room temperature. Blanching can inactivate enzym...

Embodiment 2

[0025] Embodiment 2, choose ripe, fresh " concubine laughs " lychee 10Kg, " concubine laughs " lychee flesh is thick, and core is little, is particularly suitable for making lychee meat jerky, also can shape after drying without filling. After treatment, the jerky has a good plumpness and is in the shape of "lantern meat". The sweet and sour taste is suitable, and the lychee fragrance is full. Lychee pulp is obtained by washing, peeling, and pitting the lychees, and the lychee pulp is guaranteed to be intact and not damaged. To harden the lychee pulp, put the lychee pulp into 0.2% NaHSO 3 , 0.1% citric acid, 0.2% CaCl 2 Soak in the aqueous solution for 3 hours; the hardened lychee pulp can keep the shape in the subsequent saccharification and drying, and ensure the smooth processing of preserved fruit. To scald the hardened lychee pulp, put the hardened lychee pulp into hot water at 90°C for 2 minutes; take it out and drain at room temperature. Blanching can inactivate enzy...

Embodiment 3

[0026] Embodiment 3, choose ripe, fresh " concubine laughs " lychee 10Kg, " concubine laughs " lychee meat is thick, and core is little, is particularly suitable for making lychee meat jerky, also can shape after drying without filling. After treatment, the jerky has a good plumpness and is in the shape of "lantern meat". The sweet and sour taste is suitable, and the lychee fragrance is full. Lychee pulp is obtained by washing, peeling, and pitting the lychees, and the lychee pulp is guaranteed to be intact and not damaged. To harden the lychee pulp, put the lychee pulp into 0.2% NaHSO 3 , 0.1% citric acid, 0.2% CaCl 2 Soak in the aqueous solution for 3 hours; the hardened lychee pulp can keep the shape in the subsequent saccharification and drying, and ensure the smooth processing of preserved fruit. To scald the hardened lychee pulp, put the hardened lychee pulp into hot water at 95°C for 2 minutes; take it out and drain at room temperature. Blanching can inactivate enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com