Method for predicating critical instability of brittle material through using energy characteristic value of acoustic emission signal

A technology of acoustic emission signals and energy characteristics, applied in the direction of material analysis using acoustic emission technology, can solve difficult and insufficient problems, and achieve the effect of overcoming the fast Fourier transform analysis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] In this embodiment, the brittle material to be monitored is Al 2 o 3 Ceramic, to Al 2 o 3 Ceramics were subjected to compression failure tests.

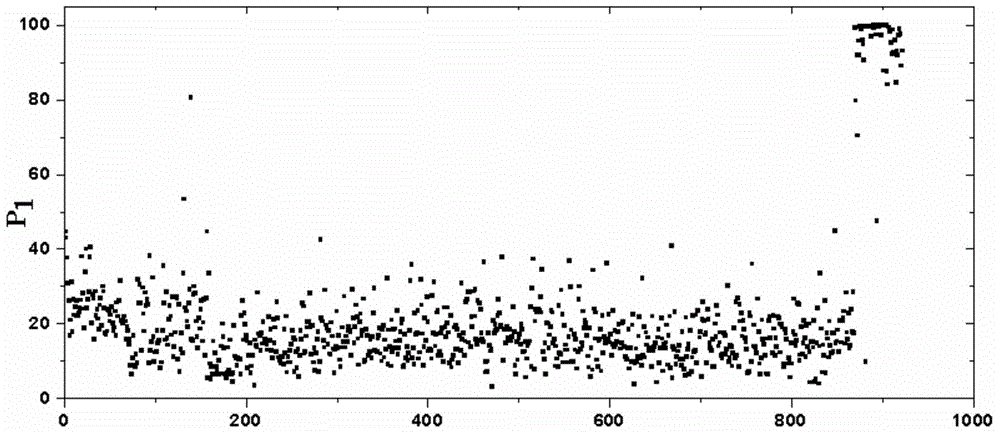

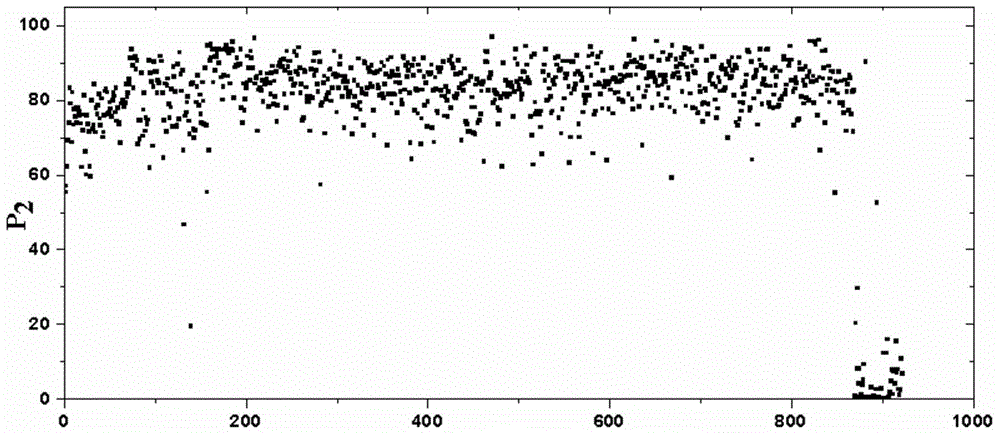

[0033] Using the method proposed by the present invention to predict critical instability of brittle materials using acoustic emission signal energy eigenvalues 2 o 3 Ceramic monitoring, the process of judging that it is in a critical instability state is as follows:

[0034] Step 1. An acoustic emission sensor is installed on the brittle material to be monitored for real-time collection of acoustic emission signals on the brittle material to be monitored.

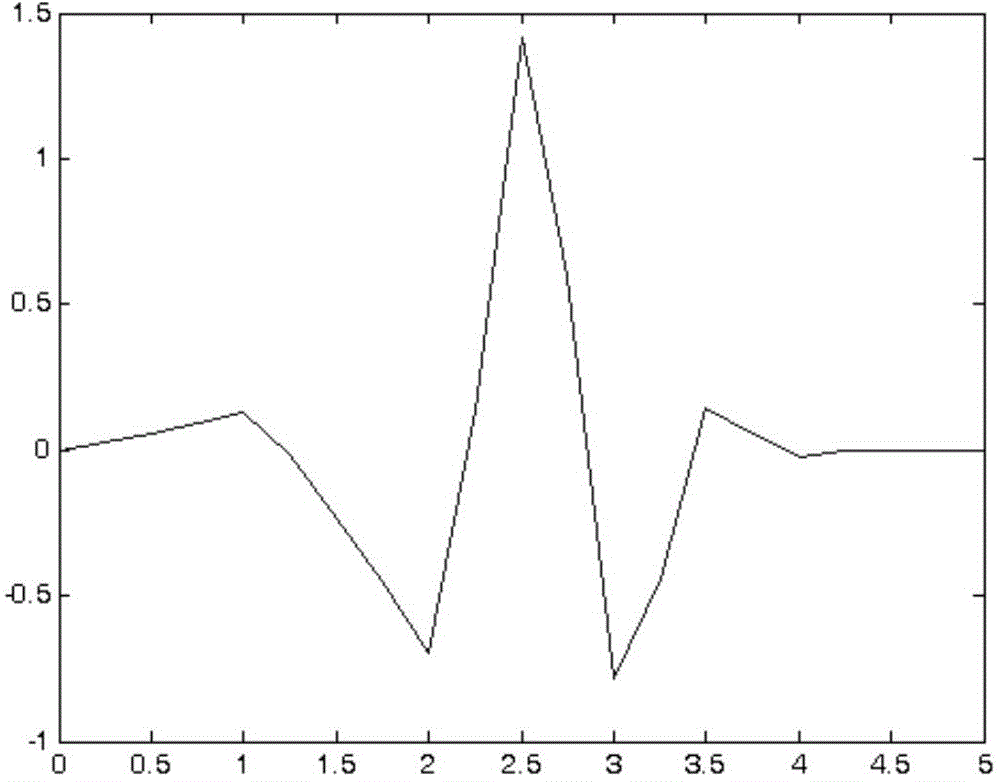

[0035] Step 2. According to the waveform characteristics of the acoustic emission signal collected in step 1, select the db3 wavelet basis, and the db3 wavelet basis function diagram is as follows figure 1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com