Steel bar full-grouting sleeve for prefabricated concrete strong connection

A technology of grouting sleeves and concrete, which is applied in the direction of building reinforcements, structural elements, building components, etc., to achieve the effect of enhancing the bonding force and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

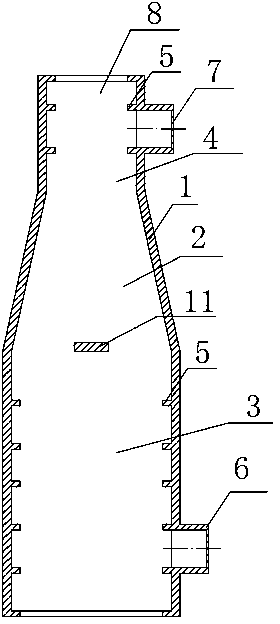

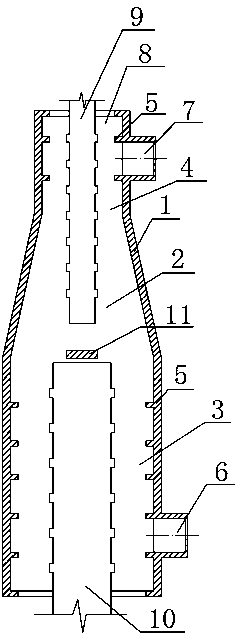

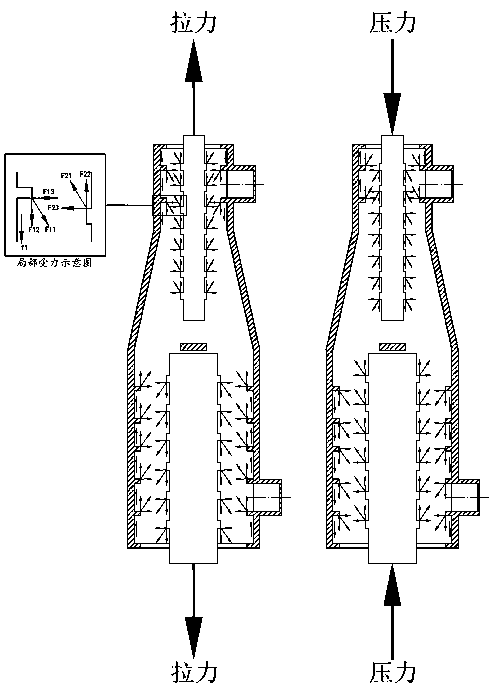

[0019] Such as figure 1 , 2 As shown, the steel bar full grouting sleeve used for the prefabricated concrete strong connection of the present invention includes a grouting sleeve body 1 with a cavity inside, the two ends of the grouting sleeve body 1 are steel bar insertion sections with different apertures, one end It is the insertion section 4 of small-diameter steel bar, and the other end is the insertion section 3 of large-diameter steel bar. The length of the insertion section 3 of large-diameter steel bar is greater than the length of the insertion section 4 of small-diameter steel bar. The key function of the grouting sleeve of the present invention is that the two ends of the grouting sleeve body 1 will be used to connect the small-diameter steel bar 9 and the large-diameter steel bar 10 respectively, and the small-diameter steel bar will penetrate the variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com