Aluminum-wood composite stand column of house

An aluminum-wood composite and column technology is applied in the field of building materials, which can solve the problems of aging and damage, low per capita wood occupation, affecting the normal use of houses, etc., and achieves improved tensile capacity, reduced construction costs, and improved bending resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

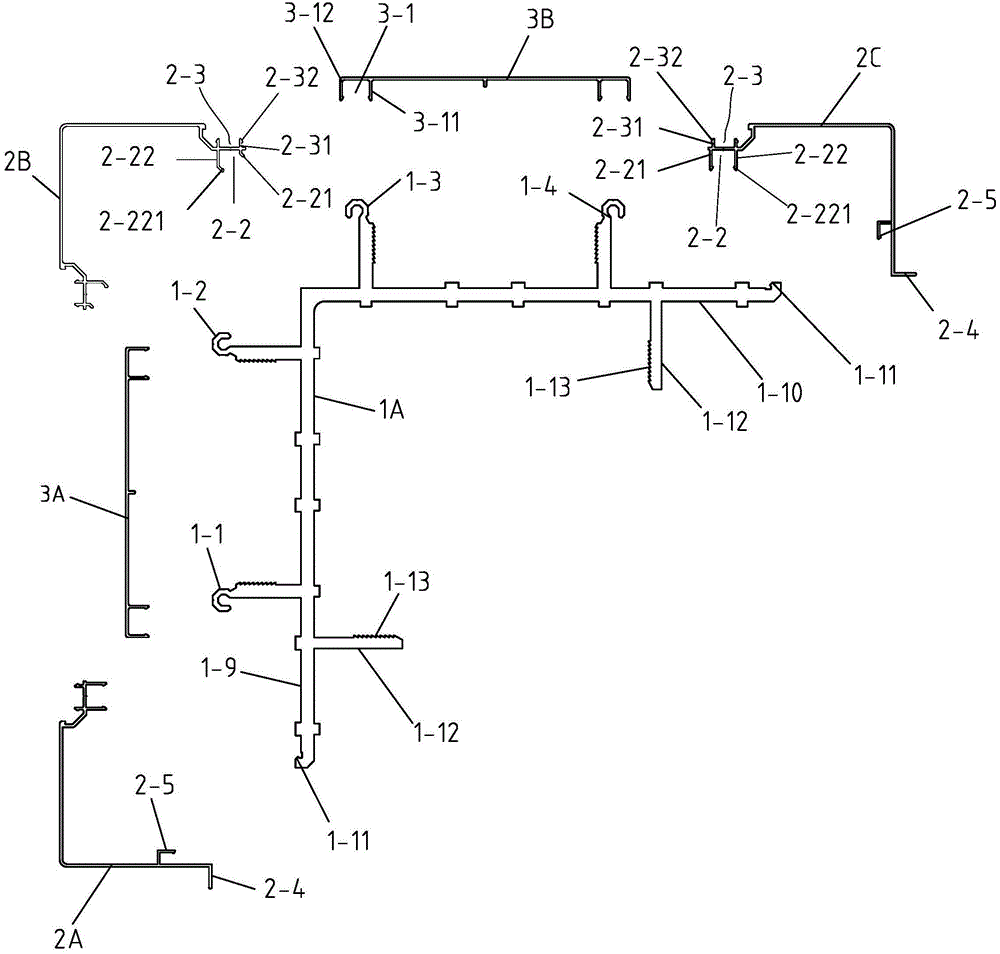

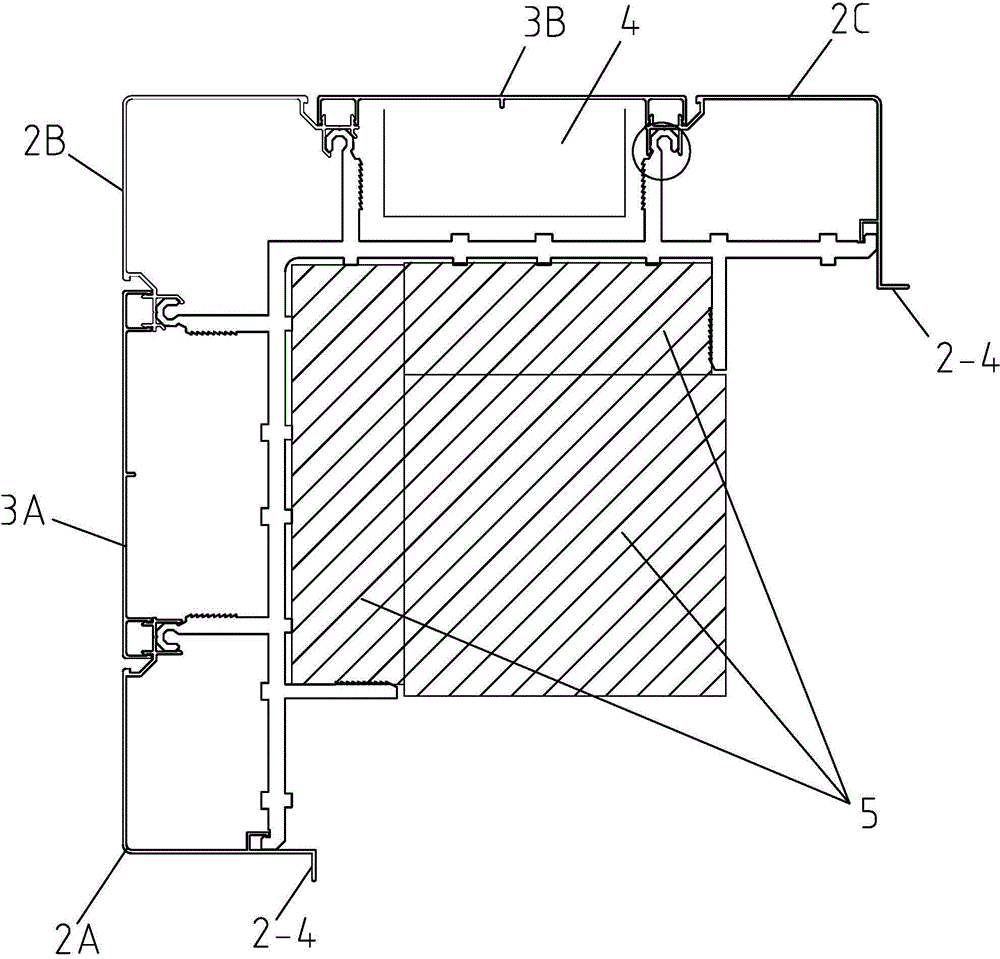

[0041] Such as figure 1 , figure 2 As shown, the present embodiment 1 provides an aluminum-wood composite column, which can be installed at the corner of the wall, including a composite wooden column (square in cross section) as a base, an aluminum column assembly and an aluminum cover plate assembly fixed on the composite wooden column, and the aluminum The cover plate assembly is positioned on the aluminum column assembly through a snap-in structure. The composite wood column is made of carbonized wood strips or wood-plastic composite strips 5 (or various types of flame-retardant treated wood or flame-retardant wood-plastic materials); the number of carbonized wood strips or wood-plastic composite strips is at least one, as shown in the figure for three.

[0042] The aluminum column assembly includes a No. 1 aluminum column 1A, and the cross section of the No. 1 aluminum column is a right-angle shape with two right-angle sides 1-9, 1-10. The two right-angled sides of th...

Embodiment 2

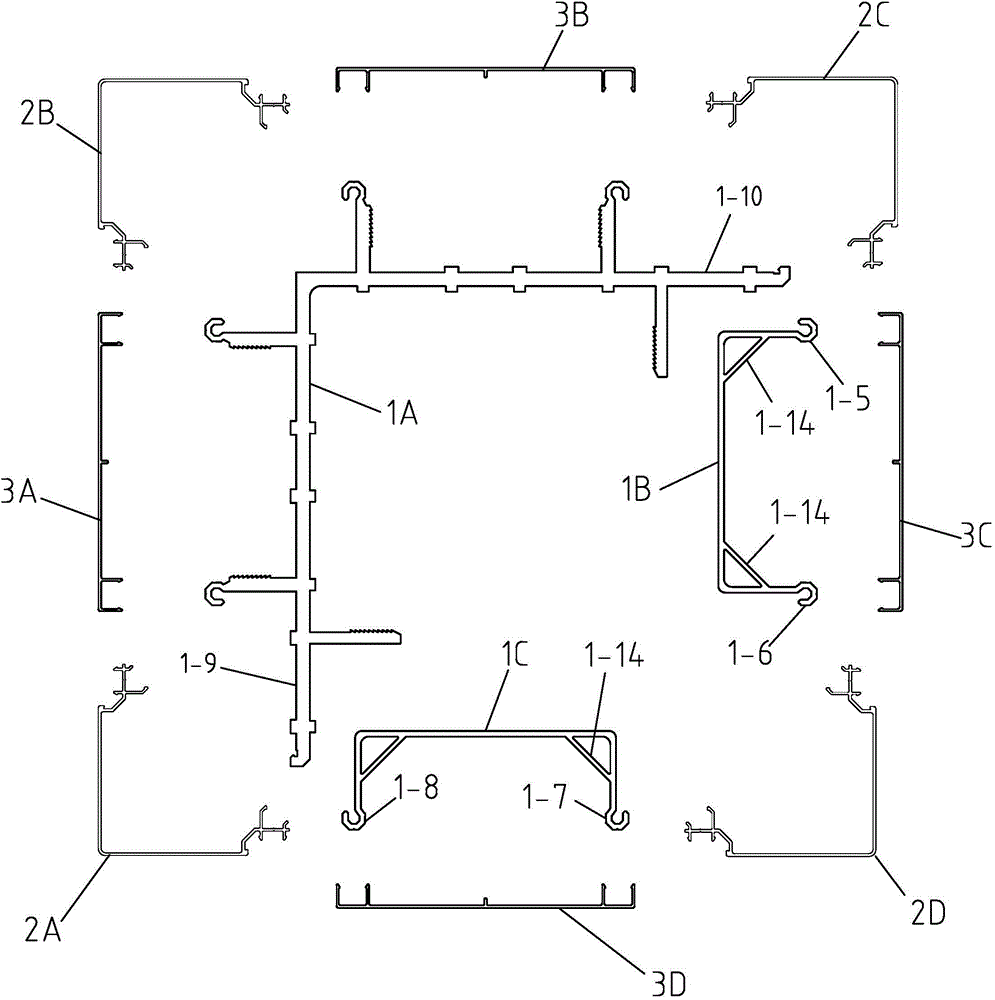

[0048] Such as image 3 , Figure 4 As shown, the aluminum-wood composite column provided in Embodiment 2 can be arranged independently. On the basis of Example 1, in this Example 2, the aluminum column assembly also includes No. 2 1B and No. 3 aluminum column 1C, and the aluminum cover assembly also includes No. 4 side aluminum cover 2D and No. 3 and No. 4 Medium aluminum cover plate 3C, 3D.

[0049] The No. 2 and No. 3 aluminum columns are respectively fixed on the other two side walls of the composite wooden column. The cross-sections of the No. 2 and No. 3 aluminum columns are groove-shaped. No. 1 and No. 6 hook plugs 1-5, 1-6, No. 7 and No. 8 hook plugs 1-7, 1-8 are respectively shaped on the top of No. 3 aluminum column both sides groove walls.

[0050] The No. 4 side aluminum cover is arranged between the No. 2 and No. 3 aluminum columns. The two sides of the No. 4 side aluminum cover are connected with the No. 6 and No. 7 hook plugs; the No. 3 middle aluminum cover i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap